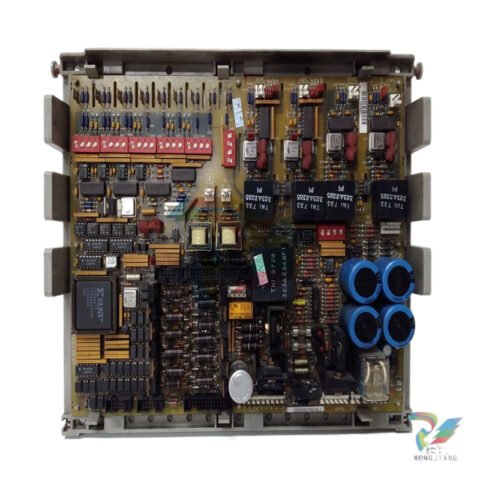

GE Electric DS200PCCAG1ABB Mark VI Control Module

Introducing the GE Electric: A New Standard in Automation Solutions

The GE Electric model stands as a beacon of innovation in the realm of automation products, showcasing a robust blend of technical prowess and versatility designed to meet the demands of modern industrial environments. With its state-of-the-art technology and user-friendly features, this model is a game-changer for businesses seeking reliability and efficiency in their operations.

Key Technical Features

At the heart of the GE Electric model is its advanced processing capability, engineered for high-performance applications. The model features a powerful microprocessor that ensures rapid data processing and seamless control over a variety of automation tasks. With integrated communication protocols, it supports both Ethernet and serial communications, allowing for flexible integration into existing systems.

The GE Electric is equipped with an extensive range of I/O options, providing unparalleled adaptability to diverse operational needs. Users can configure the model with analog and digital inputs and outputs, enhancing its suitability for both simple and complex automation tasks. Additionally, the model supports a wide voltage range, making it compatible with various power systems and reducing the need for additional converters.

One of the standout features of the GE Electric is its robust diagnostic capabilities. The built-in self-diagnostic tools and error reporting mechanisms enhance troubleshooting efficiency, enabling operators to quickly identify and rectify issues before they escalate into costly downtime. This focus on reliability is complemented by the model's durable design, built to withstand the rigors of industrial environments, ensuring long-term performance.

Usage Scenarios

The versatility of the GE Electric model opens the door to numerous practical applications across various industries. In manufacturing, it can be used to automate assembly lines, monitor equipment performance, and manage production schedules, enhancing both efficiency and productivity. The model's capability to interface with sensors and actuators allows it to control machinery with precision, ensuring optimal operation.

In the energy sector, the GE Electric model can play a vital role in monitoring and controlling power distribution systems. By integrating with smart grid technologies, it helps optimize energy usage, manage loads, and ensure reliable power delivery. This model also finds applications in water treatment facilities, where it can automate processes such as chemical dosing and filtration, thereby improving operational effectiveness and safety.

Additionally, the GE Electric is ideal for transportation systems. Its advanced control capabilities make it suitable for managing traffic signals, monitoring public transport systems, and ensuring the efficient flow of vehicular and pedestrian traffic. This adaptability makes it a preferred choice for municipalities looking to enhance their infrastructure.

Comparison with Other Models

When comparing the GE Electric model to other offerings in the GE automation products lineup, several key distinctions emerge. For instance, the GE IS220PPROS1B, while also a robust automation device, is tailored more towards process control applications and features a different set of I/O configurations suited for specific industrial tasks. In contrast, the GE Electric model offers a broader range of applications due to its flexible I/O options and enhanced processing capabilities.

Another model worth mentioning is the GE IC697MDL250, which is known for its reliability in digital control systems. However, it lacks the comprehensive diagnostic features of the GE Electric, making troubleshooting more manual and time-consuming. The GE Electric's self-diagnostic tools provide a significant advantage in maintaining operational continuity and minimizing downtime.

For users focused on energy management, the GE IS215UCVEH2AB model is designed specifically for energy applications, but it may not provide the same level of versatility as the GE Electric. The latter model excels in environments where diverse automation tasks are required, making it a more suitable choice for organizations looking to streamline multiple processes within a single platform.

Related Models

To give potential users a broader perspective, here are ten related models that complement the GE Electric within the GE automation products range:

1. GE IS200TBCIH1BBC – A versatile controller designed for a range of applications, often used in conjunction with the GE Electric.

2. GE CT7P70500470CW24 – Ideal for control applications, offering high reliability and performance.

3. GE EVMECNTM13 – A model suited for various industrial tasks with a focus on ease of use and efficiency.

4. GE IS220PAICH2A – Known for its exceptional analog processing capabilities, often used in advanced automation scenarios.

5. GE IC693CPU374 – A powerful CPU that provides robust processing for complex automation tasks.

6. GE IS200TPROH1BBB – Designed for precise control in dynamic environments, complementing the GE Electric's capabilities.

7. GE 531X307LTBAJG1 – A versatile I/O module that expands the functionality of the GE Electric model.

8. GE IS200DSPXH1DBC – Focused on digital signal processing applications, it pairs well with the GE Electric for enhanced control.

9. GE DS200SDCCG1AGD – A controller designed for demanding applications, offering advanced diagnostics and communications.

10. GE IC660ELB912G – A modular I/O system that can enhance the capabilities of the GE Electric model in various settings.

In conclusion, the GE Electric model is a powerful addition to the GE automation products portfolio, offering unmatched versatility, advanced diagnostics, and robust performance. Whether in manufacturing, energy management, or transportation systems, this model is engineered to elevate operational efficiency and reliability. With its outstanding features and adaptability to diverse applications, the GE Electric stands ready to meet the challenges of today’s dynamic industrial landscape. Explore how the GE Electric can transform your automation processes and drive your business toward a more efficient future.

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE Electric model stands as a beacon of innovation in the realm of automation products, showcasing a robust blend of technical prowess and versatility designed to meet the demands of modern industrial environments. With its state-of-the-art technology and user-friendly features, this model is a game-changer for businesses seeking reliability and efficiency in their operations.

Key Technical Features

At the heart of the GE Electric model is its advanced processing capability, engineered for high-performance applications. The model features a powerful microprocessor that ensures rapid data processing and seamless control over a variety of automation tasks. With integrated communication protocols, it supports both Ethernet and serial communications, allowing for flexible integration into existing systems.

The GE Electric is equipped with an extensive range of I/O options, providing unparalleled adaptability to diverse operational needs. Users can configure the model with analog and digital inputs and outputs, enhancing its suitability for both simple and complex automation tasks. Additionally, the model supports a wide voltage range, making it compatible with various power systems and reducing the need for additional converters.

One of the standout features of the GE Electric is its robust diagnostic capabilities. The built-in self-diagnostic tools and error reporting mechanisms enhance troubleshooting efficiency, enabling operators to quickly identify and rectify issues before they escalate into costly downtime. This focus on reliability is complemented by the model's durable design, built to withstand the rigors of industrial environments, ensuring long-term performance.

Usage Scenarios

The versatility of the GE Electric model opens the door to numerous practical applications across various industries. In manufacturing, it can be used to automate assembly lines, monitor equipment performance, and manage production schedules, enhancing both efficiency and productivity. The model's capability to interface with sensors and actuators allows it to control machinery with precision, ensuring optimal operation.

In the energy sector, the GE Electric model can play a vital role in monitoring and controlling power distribution systems. By integrating with smart grid technologies, it helps optimize energy usage, manage loads, and ensure reliable power delivery. This model also finds applications in water treatment facilities, where it can automate processes such as chemical dosing and filtration, thereby improving operational effectiveness and safety.

Additionally, the GE Electric is ideal for transportation systems. Its advanced control capabilities make it suitable for managing traffic signals, monitoring public transport systems, and ensuring the efficient flow of vehicular and pedestrian traffic. This adaptability makes it a preferred choice for municipalities looking to enhance their infrastructure.

Comparison with Other Models

When comparing the GE Electric model to other offerings in the GE automation products lineup, several key distinctions emerge. For instance, the GE IS220PPROS1B, while also a robust automation device, is tailored more towards process control applications and features a different set of I/O configurations suited for specific industrial tasks. In contrast, the GE Electric model offers a broader range of applications due to its flexible I/O options and enhanced processing capabilities.

Another model worth mentioning is the GE IC697MDL250, which is known for its reliability in digital control systems. However, it lacks the comprehensive diagnostic features of the GE Electric, making troubleshooting more manual and time-consuming. The GE Electric's self-diagnostic tools provide a significant advantage in maintaining operational continuity and minimizing downtime.

For users focused on energy management, the GE IS215UCVEH2AB model is designed specifically for energy applications, but it may not provide the same level of versatility as the GE Electric. The latter model excels in environments where diverse automation tasks are required, making it a more suitable choice for organizations looking to streamline multiple processes within a single platform.

Related Models

To give potential users a broader perspective, here are ten related models that complement the GE Electric within the GE automation products range:

1. GE IS200TBCIH1BBC – A versatile controller designed for a range of applications, often used in conjunction with the GE Electric.

2. GE CT7P70500470CW24 – Ideal for control applications, offering high reliability and performance.

3. GE EVMECNTM13 – A model suited for various industrial tasks with a focus on ease of use and efficiency.

4. GE IS220PAICH2A – Known for its exceptional analog processing capabilities, often used in advanced automation scenarios.

5. GE IC693CPU374 – A powerful CPU that provides robust processing for complex automation tasks.

6. GE IS200TPROH1BBB – Designed for precise control in dynamic environments, complementing the GE Electric's capabilities.

7. GE 531X307LTBAJG1 – A versatile I/O module that expands the functionality of the GE Electric model.

8. GE IS200DSPXH1DBC – Focused on digital signal processing applications, it pairs well with the GE Electric for enhanced control.

9. GE DS200SDCCG1AGD – A controller designed for demanding applications, offering advanced diagnostics and communications.

10. GE IC660ELB912G – A modular I/O system that can enhance the capabilities of the GE Electric model in various settings.

In conclusion, the GE Electric model is a powerful addition to the GE automation products portfolio, offering unmatched versatility, advanced diagnostics, and robust performance. Whether in manufacturing, energy management, or transportation systems, this model is engineered to elevate operational efficiency and reliability. With its outstanding features and adaptability to diverse applications, the GE Electric stands ready to meet the challenges of today’s dynamic industrial landscape. Explore how the GE Electric can transform your automation processes and drive your business toward a more efficient future.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.