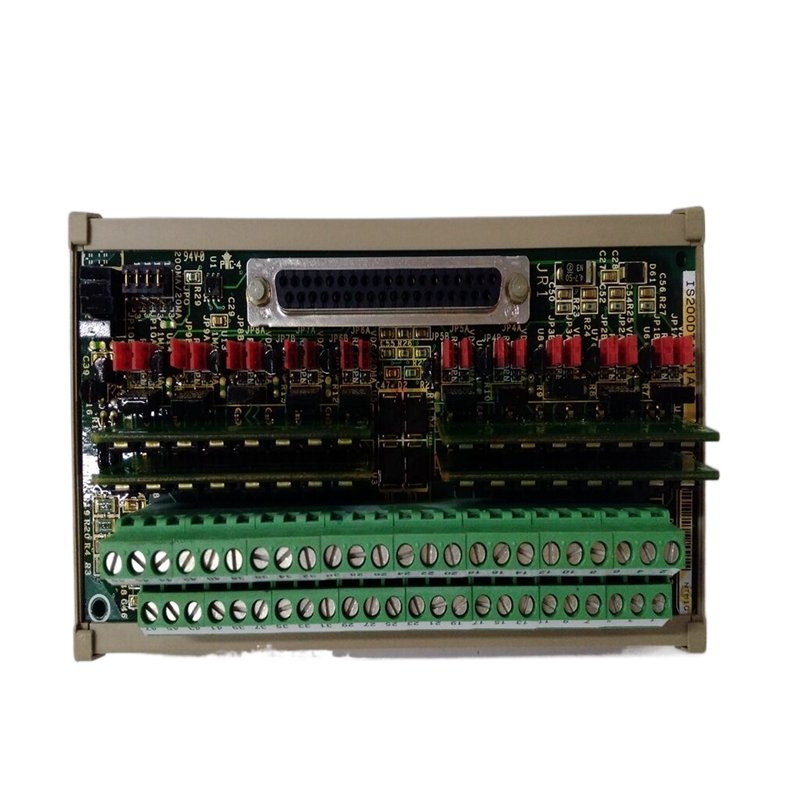

GE Fanuc DS3800NCLA High-Performance Turbine Control Module

Introducing the GE Fanuc, the pinnacle of industrial automation solutions designed to enhance operational efficiency and reliability in various sectors. Known for its robust engineering and advanced technology, the GE Fanuc series stands out in the industrial landscape, providing users with unparalleled performance, flexibility, and support.

Key Technical Features

The GE Fanuc is equipped with a multitude of key technical features that make it an ideal choice for modern industrial applications. Central to its functionality is its high-performance processing capability, allowing for seamless integration with various automation systems. Supporting a wide range of I/O modules, the GE Fanuc can accommodate diverse operational requirements, making it a versatile option for industries ranging from manufacturing to energy management.

The GE Fanuc features advanced communication protocols, including Ethernet/IP, Modbus, and more, ensuring connectivity with other GE automation products and third-party devices. Its user-friendly interface simplifies programming and monitoring, facilitating quicker project deployment and operational adjustments. Additionally, the rugged design of the GE Fanuc is built to withstand harsh industrial environments, ensuring longevity and reliability even in challenging conditions.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for numerous applications across various industries. In manufacturing, it can be utilized for real-time monitoring and control of production lines, optimizing throughput and reducing downtime. In the energy sector, the GE Fanuc excels in managing the complexities of power generation and distribution, ensuring efficient operation and regulatory compliance.

Moreover, the GE Fanuc is ideal for process automation in chemical plants, where precise control over variables like temperature, pressure, and flow rate is critical. Its adaptability allows it to integrate seamlessly with existing systems, providing a scalable solution that can grow with business needs. Whether it’s for discrete manufacturing, process control, or building automation, the GE Fanuc proves to be an essential tool for enhancing productivity and ensuring operational excellence.

Comparison with Other Models

When comparing the GE Fanuc with other models in the GE portfolio, such as the GE SR750 and the GE IS200DSPXH2DBD, it becomes evident that the GE Fanuc offers a more robust feature set tailored to diverse industrial applications. Unlike the GE SR750, which is primarily geared towards specialized applications, the GE Fanuc provides broad compatibility and functionality across various sectors.

In contrast to the GE IS200EDFFH1ABA, known for its exceptional performance in process control, the GE Fanuc stands out with its enhanced communication capabilities and modular design, allowing for easier upgrades and expansions. Compared to the GE IC693APU301, the GE Fanuc’s advanced processing power and user-friendly interface provide a more intuitive experience for operators, streamlining workflows and reducing training time.

Related Models

For those considering the GE Fanuc, it is also worthwhile to explore other related models within the GE family that complement its capabilities. These include:

1. GE SR750 – A high-performance controller designed for specialized applications.

2. GE IC697MDL740 – A versatile I/O module that expands the functionality of various GE automation products.

3. GE IS200DSFCG1AEB – A digital signal processor for advanced control applications.

4. GE IC660BBA020 – A powerful bus interface for enhanced communication between devices.

5. GE DS200DDTBG2A – A dynamic digital output module catering to specific process requirements.

6. GE IS200DSPXH2DBD – A digital signal processor optimized for process automation.

7. GE IS220PPDAH1A – A process control module for precise management of production variables.

8. GE IC693ACC302 – An advanced communication module that supports various protocols.

9. GE IS200JPDMG1ADC – A module designed for data acquisition and process monitoring.

10. GE IS420YDOAS1B – A versatile output module that lends itself to various automation needs.

Each of these models offers unique features and capabilities that can be integrated with the GE Fanuc, providing a comprehensive solution for any automation challenge.

Conclusion

The GE Fanuc represents the forefront of industrial automation technology, offering a blend of performance, versatility, and reliability that is essential for modern manufacturing and process management. Its key technical features, combined with the broad range of usage scenarios, make it an invaluable tool for businesses looking to optimize their operations.

When compared to other models, the GE Fanuc shines with its advanced processing capabilities and compatibility with various GE automation products, making it a smart investment for future-proofing your operations. With its extensive range of related models, users can build a tailored automation ecosystem that meets their specific needs.

Discover the power of the GE Fanuc today and elevate your industrial automation capabilities to new heights. Whether you're looking to enhance productivity, improve process control, or streamline your operations, the GE Fanuc is the solution you've been searching for. Embrace the future of automation with GE Fanuc and experience the difference it can make in your business.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE Fanuc is equipped with a multitude of key technical features that make it an ideal choice for modern industrial applications. Central to its functionality is its high-performance processing capability, allowing for seamless integration with various automation systems. Supporting a wide range of I/O modules, the GE Fanuc can accommodate diverse operational requirements, making it a versatile option for industries ranging from manufacturing to energy management.

The GE Fanuc features advanced communication protocols, including Ethernet/IP, Modbus, and more, ensuring connectivity with other GE automation products and third-party devices. Its user-friendly interface simplifies programming and monitoring, facilitating quicker project deployment and operational adjustments. Additionally, the rugged design of the GE Fanuc is built to withstand harsh industrial environments, ensuring longevity and reliability even in challenging conditions.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for numerous applications across various industries. In manufacturing, it can be utilized for real-time monitoring and control of production lines, optimizing throughput and reducing downtime. In the energy sector, the GE Fanuc excels in managing the complexities of power generation and distribution, ensuring efficient operation and regulatory compliance.

Moreover, the GE Fanuc is ideal for process automation in chemical plants, where precise control over variables like temperature, pressure, and flow rate is critical. Its adaptability allows it to integrate seamlessly with existing systems, providing a scalable solution that can grow with business needs. Whether it’s for discrete manufacturing, process control, or building automation, the GE Fanuc proves to be an essential tool for enhancing productivity and ensuring operational excellence.

Comparison with Other Models

When comparing the GE Fanuc with other models in the GE portfolio, such as the GE SR750 and the GE IS200DSPXH2DBD, it becomes evident that the GE Fanuc offers a more robust feature set tailored to diverse industrial applications. Unlike the GE SR750, which is primarily geared towards specialized applications, the GE Fanuc provides broad compatibility and functionality across various sectors.

In contrast to the GE IS200EDFFH1ABA, known for its exceptional performance in process control, the GE Fanuc stands out with its enhanced communication capabilities and modular design, allowing for easier upgrades and expansions. Compared to the GE IC693APU301, the GE Fanuc’s advanced processing power and user-friendly interface provide a more intuitive experience for operators, streamlining workflows and reducing training time.

Related Models

For those considering the GE Fanuc, it is also worthwhile to explore other related models within the GE family that complement its capabilities. These include:

1. GE SR750 – A high-performance controller designed for specialized applications.

2. GE IC697MDL740 – A versatile I/O module that expands the functionality of various GE automation products.

3. GE IS200DSFCG1AEB – A digital signal processor for advanced control applications.

4. GE IC660BBA020 – A powerful bus interface for enhanced communication between devices.

5. GE DS200DDTBG2A – A dynamic digital output module catering to specific process requirements.

6. GE IS200DSPXH2DBD – A digital signal processor optimized for process automation.

7. GE IS220PPDAH1A – A process control module for precise management of production variables.

8. GE IC693ACC302 – An advanced communication module that supports various protocols.

9. GE IS200JPDMG1ADC – A module designed for data acquisition and process monitoring.

10. GE IS420YDOAS1B – A versatile output module that lends itself to various automation needs.

Each of these models offers unique features and capabilities that can be integrated with the GE Fanuc, providing a comprehensive solution for any automation challenge.

Conclusion

The GE Fanuc represents the forefront of industrial automation technology, offering a blend of performance, versatility, and reliability that is essential for modern manufacturing and process management. Its key technical features, combined with the broad range of usage scenarios, make it an invaluable tool for businesses looking to optimize their operations.

When compared to other models, the GE Fanuc shines with its advanced processing capabilities and compatibility with various GE automation products, making it a smart investment for future-proofing your operations. With its extensive range of related models, users can build a tailored automation ecosystem that meets their specific needs.

Discover the power of the GE Fanuc today and elevate your industrial automation capabilities to new heights. Whether you're looking to enhance productivity, improve process control, or streamline your operations, the GE Fanuc is the solution you've been searching for. Embrace the future of automation with GE Fanuc and experience the difference it can make in your business.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.