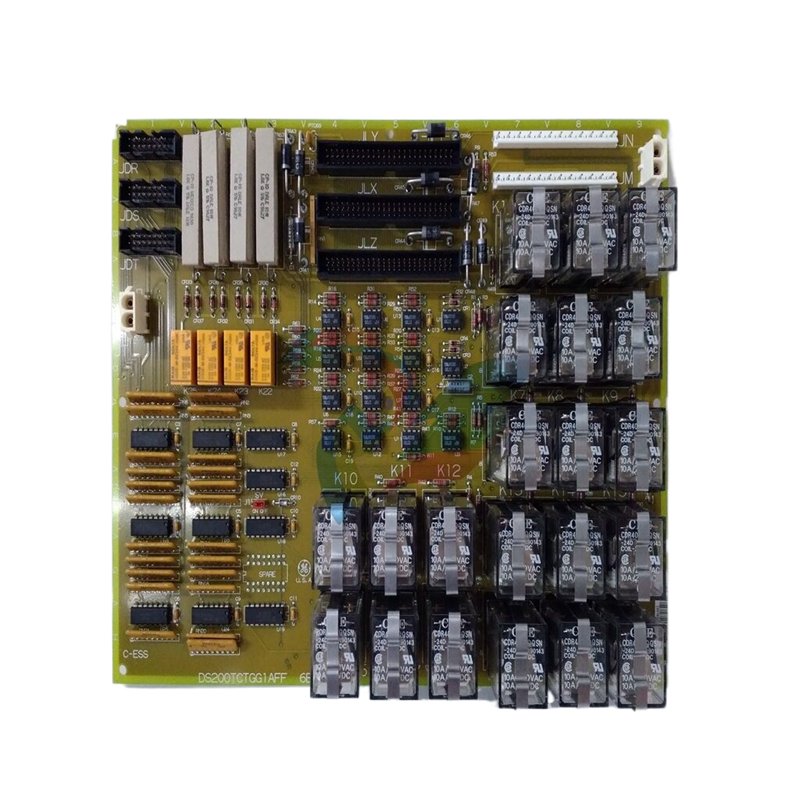

GE Fanuc HE693RTD601R Input Module Precision RTD Measurement Solution

Introducing the GE Fanuc: A Benchmark in Industrial Automation

The GE Fanuc series represents a pinnacle of innovation within the realm of industrial automation products. Renowned for their reliability and advanced technology, these systems are designed to enhance operational efficiency across various sectors. Whether you're in manufacturing, energy, or process control, GE Fanuc products embody the perfect blend of performance and adaptability, making them indispensable tools for modern enterprises.

Key Technical Features

The GE Fanuc models come equipped with an array of cutting-edge technical features that set them apart from the competition. Key highlights include:

1. **High Processing Power**: With robust CPUs such as the IC695CPE310-ABAH and IC693APU301, the GE Fanuc series delivers exceptional processing speeds, enabling quick data handling and real-time decision-making.

2. **Scalability**: Designed to accommodate future growth, GE Fanuc systems can be easily expanded with additional modules like the IC697MDL740 and IC200UAL005. This flexibility ensures that businesses can adapt their automation solutions without significant upfront investments.

3. **Comprehensive I/O Options**: The series includes various input/output modules, such as the IS200DSPXH2DBD and DS200DDTBG2A, allowing for seamless integration with sensors, actuators, and other industrial devices.

4. **Advanced Networking Capabilities**: GE Fanuc products support multiple communication protocols, including Ethernet, allowing for efficient integration into existing network infrastructures. Models like the IC660BBA020 facilitate superior connectivity and data exchange across systems.

5. **Robust Safety Features**: Safety is paramount in industrial environments. The GE Fanuc series incorporates advanced safety features to protect both personnel and equipment, making them suitable for critical applications.

6. **User-Friendly Interface**: The intuitive programming environment and user interface streamline the configuration and operation of GE Fanuc systems. This ease of use reduces training time and accelerates deployment.

Usage Scenarios

The versatility of GE Fanuc systems allows them to be employed in a wide range of applications. Here are some typical usage scenarios:

– **Manufacturing Automation**: GE Fanuc products are ideal for controlling and monitoring production lines, ensuring maximum efficiency and minimal downtime. For example, the GE SR750 model can manage complex assembly operations, adapting to changing production needs.

– **Energy Management**: In the energy sector, GE automation products play a crucial role in managing generation and distribution systems. They enable real-time monitoring and control of energy flow, contributing to optimized performance and reduced operational costs.

– **Process Control**: Industries such as oil and gas, chemicals, and pharmaceuticals rely on GE Fanuc systems for precise process control. The IS200EDFFH1ABA model can effectively manage critical parameters, ensuring product quality and compliance with regulatory standards.

– **Transportation Systems**: The GE Fanuc series is also valuable in transportation and logistics, where it can manage automated warehousing systems and facilitate efficient material handling.

Comparison with Other Models

When considering GE Fanuc products, it is essential to evaluate how they measure up against other models in the market. Compared to other brands, GE Fanuc systems excel in several areas:

– **Reliability**: GE Fanuc models such as the IS200TRPGH1BDE and IC694PWR331 are built to withstand harsh industrial conditions, offering exceptional durability and reliability over time.

– **Integration**: While many brands offer automation solutions, GE Fanuc's extensive compatibility with existing infrastructures sets it apart. The ability to integrate seamlessly with other GE products (like the GE IS220PPDAH1A) and third-party devices enhances operational flexibility.

– **Support and Resources**: GE provides extensive support and resources for its automation products, including comprehensive documentation and customer service, ensuring users can maximize their system's potential.

Related Models

In addition to the flagship GE Fanuc models, several related products complement the automation ecosystem. These include:

1. GE SR750

2. GE IC697MDL740

3. GE IS200DSFCG1AEB

4. GE IC660BBA020

5. GE DS200DDTBG2A

6. GE IS200DSPXH2DBD

7. GE IS220PPDAH1A

8. GE IS200VTURH1BAC

9. GE IC695CPE310-ABAH

10. GE IS200JPDMG1ADC

These models serve various functions and can be integrated as part of a comprehensive GE automation solution, enhancing overall operational efficiency.

Conclusion

In conclusion, the GE Fanuc series stands out as a leader in the field of industrial automation products. With their high processing power, scalability, and advanced safety features, these systems are perfect for a wide array of applications, from manufacturing to energy management. Their ability to integrate seamlessly into existing infrastructures and their exceptional reliability make them a preferred choice for businesses looking to optimize their operations.

Investing in GE Fanuc products not only ensures the enhancement of productivity but also provides peace of mind with the backing of a trusted brand in automation. Whether you are upgrading existing systems or implementing a new automation solution, GE Fanuc is the key to unlocking your operational potential. Explore the world of GE automation products and experience the difference that quality and innovation can make in your industrial processes.

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE Fanuc series represents a pinnacle of innovation within the realm of industrial automation products. Renowned for their reliability and advanced technology, these systems are designed to enhance operational efficiency across various sectors. Whether you're in manufacturing, energy, or process control, GE Fanuc products embody the perfect blend of performance and adaptability, making them indispensable tools for modern enterprises.

Key Technical Features

The GE Fanuc models come equipped with an array of cutting-edge technical features that set them apart from the competition. Key highlights include:

1. **High Processing Power**: With robust CPUs such as the IC695CPE310-ABAH and IC693APU301, the GE Fanuc series delivers exceptional processing speeds, enabling quick data handling and real-time decision-making.

2. **Scalability**: Designed to accommodate future growth, GE Fanuc systems can be easily expanded with additional modules like the IC697MDL740 and IC200UAL005. This flexibility ensures that businesses can adapt their automation solutions without significant upfront investments.

3. **Comprehensive I/O Options**: The series includes various input/output modules, such as the IS200DSPXH2DBD and DS200DDTBG2A, allowing for seamless integration with sensors, actuators, and other industrial devices.

4. **Advanced Networking Capabilities**: GE Fanuc products support multiple communication protocols, including Ethernet, allowing for efficient integration into existing network infrastructures. Models like the IC660BBA020 facilitate superior connectivity and data exchange across systems.

5. **Robust Safety Features**: Safety is paramount in industrial environments. The GE Fanuc series incorporates advanced safety features to protect both personnel and equipment, making them suitable for critical applications.

6. **User-Friendly Interface**: The intuitive programming environment and user interface streamline the configuration and operation of GE Fanuc systems. This ease of use reduces training time and accelerates deployment.

Usage Scenarios

The versatility of GE Fanuc systems allows them to be employed in a wide range of applications. Here are some typical usage scenarios:

– **Manufacturing Automation**: GE Fanuc products are ideal for controlling and monitoring production lines, ensuring maximum efficiency and minimal downtime. For example, the GE SR750 model can manage complex assembly operations, adapting to changing production needs.

– **Energy Management**: In the energy sector, GE automation products play a crucial role in managing generation and distribution systems. They enable real-time monitoring and control of energy flow, contributing to optimized performance and reduced operational costs.

– **Process Control**: Industries such as oil and gas, chemicals, and pharmaceuticals rely on GE Fanuc systems for precise process control. The IS200EDFFH1ABA model can effectively manage critical parameters, ensuring product quality and compliance with regulatory standards.

– **Transportation Systems**: The GE Fanuc series is also valuable in transportation and logistics, where it can manage automated warehousing systems and facilitate efficient material handling.

Comparison with Other Models

When considering GE Fanuc products, it is essential to evaluate how they measure up against other models in the market. Compared to other brands, GE Fanuc systems excel in several areas:

– **Reliability**: GE Fanuc models such as the IS200TRPGH1BDE and IC694PWR331 are built to withstand harsh industrial conditions, offering exceptional durability and reliability over time.

– **Integration**: While many brands offer automation solutions, GE Fanuc's extensive compatibility with existing infrastructures sets it apart. The ability to integrate seamlessly with other GE products (like the GE IS220PPDAH1A) and third-party devices enhances operational flexibility.

– **Support and Resources**: GE provides extensive support and resources for its automation products, including comprehensive documentation and customer service, ensuring users can maximize their system's potential.

Related Models

In addition to the flagship GE Fanuc models, several related products complement the automation ecosystem. These include:

1. GE SR750

2. GE IC697MDL740

3. GE IS200DSFCG1AEB

4. GE IC660BBA020

5. GE DS200DDTBG2A

6. GE IS200DSPXH2DBD

7. GE IS220PPDAH1A

8. GE IS200VTURH1BAC

9. GE IC695CPE310-ABAH

10. GE IS200JPDMG1ADC

These models serve various functions and can be integrated as part of a comprehensive GE automation solution, enhancing overall operational efficiency.

Conclusion

In conclusion, the GE Fanuc series stands out as a leader in the field of industrial automation products. With their high processing power, scalability, and advanced safety features, these systems are perfect for a wide array of applications, from manufacturing to energy management. Their ability to integrate seamlessly into existing infrastructures and their exceptional reliability make them a preferred choice for businesses looking to optimize their operations.

Investing in GE Fanuc products not only ensures the enhancement of productivity but also provides peace of mind with the backing of a trusted brand in automation. Whether you are upgrading existing systems or implementing a new automation solution, GE Fanuc is the key to unlocking your operational potential. Explore the world of GE automation products and experience the difference that quality and innovation can make in your industrial processes.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.