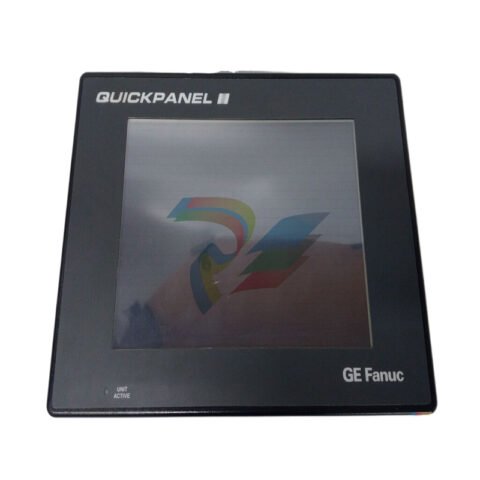

GE Fanuc IC200CHS001 A Cutting-edge VersaMax PLC

Introducing the GE Fanuc: A Leader in Automation Technology

The GE Fanuc brand stands as a hallmark of innovation and reliability in the realm of automation products. With a legacy of excellence, GE Fanuc delivers cutting-edge solutions tailored for various industrial applications. Whether you’re streamlining a manufacturing process or enhancing control systems, the GE Fanuc series is designed to meet your needs with precision and efficiency.

Key Technical Features

The GE Fanuc series boasts an array of impressive technical features that set it apart from competitors. Notably, models like the GE IS200TBCIH1BBC and GE IS220PPROS1B highlight the following attributes:

1. **Robust Processing Power**: GE Fanuc models incorporate advanced processors, ensuring fast execution of complex algorithms, real-time processing, and effective multitasking capabilities. This is essential for applications requiring high-speed data processing and instant decision-making.

2. **Versatile Communication Protocols**: The GE Fanuc series is equipped with a multitude of communication options, including Ethernet/IP, Modbus, and Profibus. This versatility enables seamless integration with existing systems, facilitating smooth data exchange across diverse platforms.

3. **Modular Design**: Many GE Fanuc products, such as the GE IC697MDL250 and GE IS215UCVEH2AB, feature a modular design that allows for easy scalability and maintenance. Users can customize their systems by adding or replacing components without extensive downtime.

4. **High Reliability and Durability**: Built to withstand harsh industrial environments, GE Fanuc products are rigorously tested for durability. Models like the GE DS200CTBAG1ADD and GE IC660ELB912G are designed to operate reliably even in extreme conditions, ensuring longevity and consistent performance.

5. **User-Friendly Interface**: The intuitive interface of GE Fanuc systems simplifies operation and reduces training time for personnel. The graphical displays and straightforward navigation enhance user experience, allowing operators to monitor and control processes with ease.

Usage Scenarios

The GE Fanuc series is incredibly versatile, finding applications across multiple industries. Here are a few key scenarios:

1. **Manufacturing**: In a manufacturing setting, GE Fanuc automation products streamline production lines, enhance assembly processes, and optimize resource allocation. The GE IS220PRTDH1A model, for example, effectively manages temperature control in manufacturing processes, ensuring quality and efficiency.

2. **Energy Management**: GE Fanuc solutions are pivotal in the energy sector, providing control and monitoring for renewable energy systems, traditional power plants, and electric grids. The GE IS200EPSMG2ADC model is particularly suited for energy applications, offering advanced functionalities for managing energy distribution and consumption.

3. **Transportation**: The robust communication capabilities of GE Fanuc products make them ideal for transportation management systems. They help monitor traffic flows, control signals, and manage logistics in real-time, ensuring safer and more efficient transport systems.

4. **Water Treatment**: In the water treatment industry, models like the GE 531X307LTBAJG1 are employed to regulate chemical dosing, monitor water quality, and optimize pump operations, ensuring clean and safe water supply.

5. **Building Automation**: GE Fanuc products are extensively used in building automation systems to monitor HVAC systems, lighting, and security, enhancing energy efficiency and occupant comfort.

Comparison with Other Models

When compared to other models within the GE automation products lineup, the GE Fanuc series distinguishes itself with its advanced features and operational flexibility. For instance, while the GE IC670MDL740J offers strong performance, the GE Fanuc models provide more extensive communication options and greater processing power, making them more suitable for complex applications.

In contrast to the GE IS200TPROH1BCB, which is primarily focused on control functionalities, the GE Fanuc models offer a broader range of features, including enhanced data processing capabilities and user-friendly interfaces, making them more adaptable to diverse industrial needs.

Reference Related Models

For those exploring GE Fanuc products, a variety of related models offer complementary functionalities:

1. **GE IS200DSPXH1DBC**: A powerful digital signal processor ideal for motion control applications.

2. **GE DS200TCQAG1BHF**: A versatile control module used in various automation systems.

3. **GE IC670CHS001E**: A high-performance control system designed for industrial processes.

4. **GE IS210AEBIH3BEC**: A robust automation controller tailored for dynamic operations.

5. **GE IC693CPU374**: A reliable CPU module ideal for complex control tasks.

6. **GE IS220PAICH2A**: A versatile input/output controller suitable for various applications.

7. **GE DS215TCQAG1BZZ01A**: A control module designed for temperature control applications.

8. **GE IC660EBD020**: A communication module that facilitates data exchange within automation systems.

9. **GE CP238/TA1**: A control panel that enhances user interaction with automation processes.

10. **GE IC698CMX016**: A powerful communication module designed for high-speed data transfer.

Conclusion

The GE Fanuc series represents the pinnacle of automation technology, combining innovative features, exceptional performance, and unmatched reliability. Whether you are in manufacturing, energy, transportation, or building automation, GE Fanuc products are engineered to elevate your operational efficiency. With their extensive range of models, businesses can find the perfect solution to meet their unique automation needs. Trust in GE Fanuc, where advanced technology meets practical application, paving the way for a smarter, more efficient future in automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE Fanuc brand stands as a hallmark of innovation and reliability in the realm of automation products. With a legacy of excellence, GE Fanuc delivers cutting-edge solutions tailored for various industrial applications. Whether you’re streamlining a manufacturing process or enhancing control systems, the GE Fanuc series is designed to meet your needs with precision and efficiency.

Key Technical Features

The GE Fanuc series boasts an array of impressive technical features that set it apart from competitors. Notably, models like the GE IS200TBCIH1BBC and GE IS220PPROS1B highlight the following attributes:

1. **Robust Processing Power**: GE Fanuc models incorporate advanced processors, ensuring fast execution of complex algorithms, real-time processing, and effective multitasking capabilities. This is essential for applications requiring high-speed data processing and instant decision-making.

2. **Versatile Communication Protocols**: The GE Fanuc series is equipped with a multitude of communication options, including Ethernet/IP, Modbus, and Profibus. This versatility enables seamless integration with existing systems, facilitating smooth data exchange across diverse platforms.

3. **Modular Design**: Many GE Fanuc products, such as the GE IC697MDL250 and GE IS215UCVEH2AB, feature a modular design that allows for easy scalability and maintenance. Users can customize their systems by adding or replacing components without extensive downtime.

4. **High Reliability and Durability**: Built to withstand harsh industrial environments, GE Fanuc products are rigorously tested for durability. Models like the GE DS200CTBAG1ADD and GE IC660ELB912G are designed to operate reliably even in extreme conditions, ensuring longevity and consistent performance.

5. **User-Friendly Interface**: The intuitive interface of GE Fanuc systems simplifies operation and reduces training time for personnel. The graphical displays and straightforward navigation enhance user experience, allowing operators to monitor and control processes with ease.

Usage Scenarios

The GE Fanuc series is incredibly versatile, finding applications across multiple industries. Here are a few key scenarios:

1. **Manufacturing**: In a manufacturing setting, GE Fanuc automation products streamline production lines, enhance assembly processes, and optimize resource allocation. The GE IS220PRTDH1A model, for example, effectively manages temperature control in manufacturing processes, ensuring quality and efficiency.

2. **Energy Management**: GE Fanuc solutions are pivotal in the energy sector, providing control and monitoring for renewable energy systems, traditional power plants, and electric grids. The GE IS200EPSMG2ADC model is particularly suited for energy applications, offering advanced functionalities for managing energy distribution and consumption.

3. **Transportation**: The robust communication capabilities of GE Fanuc products make them ideal for transportation management systems. They help monitor traffic flows, control signals, and manage logistics in real-time, ensuring safer and more efficient transport systems.

4. **Water Treatment**: In the water treatment industry, models like the GE 531X307LTBAJG1 are employed to regulate chemical dosing, monitor water quality, and optimize pump operations, ensuring clean and safe water supply.

5. **Building Automation**: GE Fanuc products are extensively used in building automation systems to monitor HVAC systems, lighting, and security, enhancing energy efficiency and occupant comfort.

Comparison with Other Models

When compared to other models within the GE automation products lineup, the GE Fanuc series distinguishes itself with its advanced features and operational flexibility. For instance, while the GE IC670MDL740J offers strong performance, the GE Fanuc models provide more extensive communication options and greater processing power, making them more suitable for complex applications.

In contrast to the GE IS200TPROH1BCB, which is primarily focused on control functionalities, the GE Fanuc models offer a broader range of features, including enhanced data processing capabilities and user-friendly interfaces, making them more adaptable to diverse industrial needs.

Reference Related Models

For those exploring GE Fanuc products, a variety of related models offer complementary functionalities:

1. **GE IS200DSPXH1DBC**: A powerful digital signal processor ideal for motion control applications.

2. **GE DS200TCQAG1BHF**: A versatile control module used in various automation systems.

3. **GE IC670CHS001E**: A high-performance control system designed for industrial processes.

4. **GE IS210AEBIH3BEC**: A robust automation controller tailored for dynamic operations.

5. **GE IC693CPU374**: A reliable CPU module ideal for complex control tasks.

6. **GE IS220PAICH2A**: A versatile input/output controller suitable for various applications.

7. **GE DS215TCQAG1BZZ01A**: A control module designed for temperature control applications.

8. **GE IC660EBD020**: A communication module that facilitates data exchange within automation systems.

9. **GE CP238/TA1**: A control panel that enhances user interaction with automation processes.

10. **GE IC698CMX016**: A powerful communication module designed for high-speed data transfer.

Conclusion

The GE Fanuc series represents the pinnacle of automation technology, combining innovative features, exceptional performance, and unmatched reliability. Whether you are in manufacturing, energy, transportation, or building automation, GE Fanuc products are engineered to elevate your operational efficiency. With their extensive range of models, businesses can find the perfect solution to meet their unique automation needs. Trust in GE Fanuc, where advanced technology meets practical application, paving the way for a smarter, more efficient future in automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

.jpg)

There are no reviews yet.