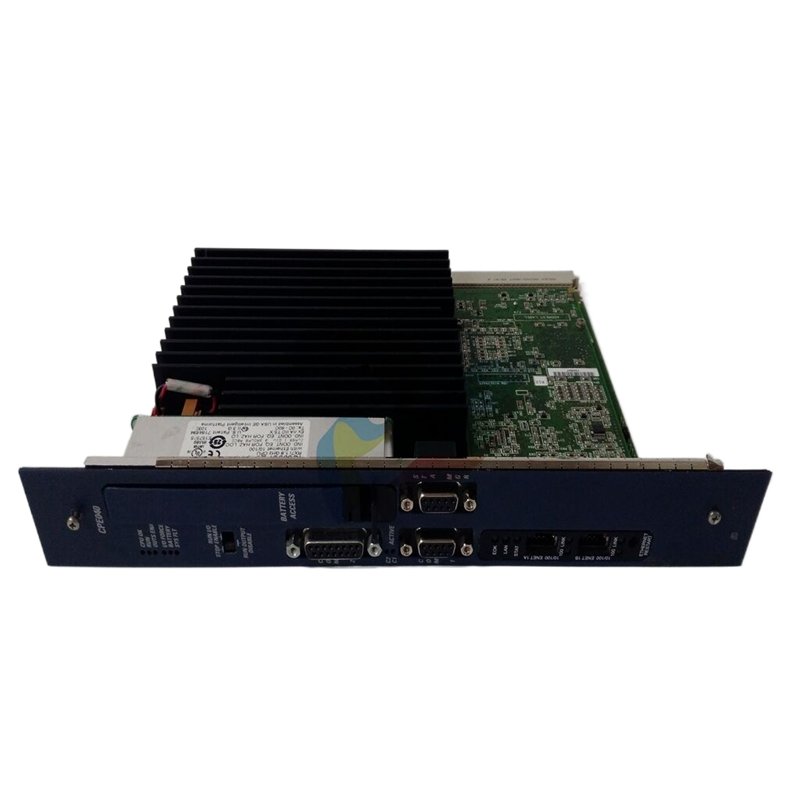

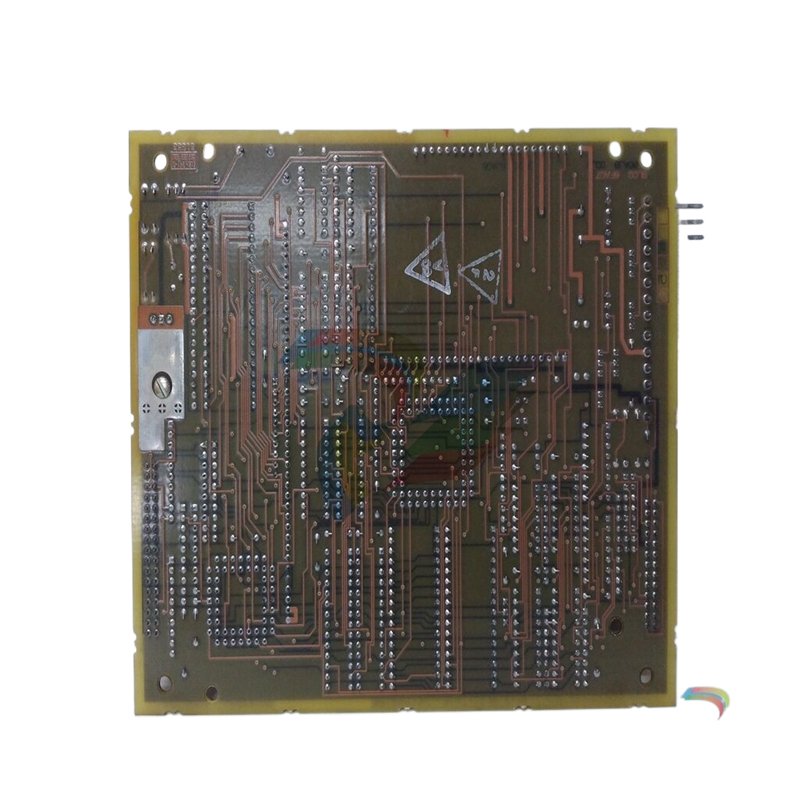

GE FANUC IC600FP608K IC600LX624L Memory Module for Industrial Automation

Introducing the GE FANUC: A Pinnacle of Automation Excellence

In the rapidly evolving landscape of industrial automation, the GE FANUC stands out as a robust solution tailored to meet the demands of modern manufacturing and control systems. This model epitomizes innovation, reliability, and high performance, making it an invaluable asset for businesses looking to enhance their operational efficiency.

Key Technical Features

The GE FANUC is designed with cutting-edge technology that ensures seamless integration into various industrial applications. Some of its standout features include:

1. **High-Performance Processing**: Equipped with a powerful microprocessor, the GE FANUC delivers rapid data processing capabilities, enabling real-time monitoring and control of complex systems.

2. **Versatile Communication Protocols**: The GE FANUC supports multiple communication protocols, including Ethernet, ControlNet, and DeviceNet, allowing for flexible integration with existing systems and enhancing interoperability with other devices.

3. **Robust I/O Capabilities**: With a wide range of input and output options, the GE FANUC is capable of handling diverse sensor and actuator configurations, making it suitable for various applications from simple control tasks to complex automation processes.

4. **Scalability**: Designed to grow with your business needs, the GE FANUC can easily be expanded with additional modules, ensuring that your automation system can adapt to changing operational requirements.

5. **User-Friendly Interface**: The GE FANUC features an intuitive interface that simplifies programming and troubleshooting, reducing downtime and enhancing overall productivity.

6. **Advanced Diagnostics**: Built-in diagnostic tools provide real-time feedback on system performance, allowing for proactive maintenance and minimizing unexpected failures.

Usage Scenarios

The versatility of the GE FANUC makes it suitable for a variety of industrial applications. It excels in:

– **Manufacturing Automation**: Streamlining production processes in assembly lines, packaging, and quality control.

– **Process Control**: Monitoring and controlling parameters in industries such as chemicals, pharmaceuticals, and food processing, ensuring optimal conditions and compliance with safety standards.

– **Energy Management**: Enhancing efficiency in energy distribution and management systems, contributing to reduced operational costs and improved sustainability.

– **Building Automation**: Integrating with HVAC, lighting, and security systems to optimize energy usage and improve occupant comfort.

Comparison with Other Models

When compared to other models within the GE automation products portfolio, the GE FANUC distinguishes itself through its balance of performance and flexibility. For instance, while the GE IS200TBCIH1BBC focuses on dedicated control tasks, the FANUC's modular design allows it to cater to a broader range of applications. Likewise, compared to the GE IC697MDL250, which offers specific I/O capabilities, the GE FANUC’s versatility allows it to adapt to various configurations and requirements.

Additionally, models like the GE IS220PAICH2A are excellent for specific applications but may lack the comprehensive communication options that the GE FANUC provides. This makes the FANUC a go-to choice for organizations that prioritize future-proof solutions capable of evolving with their technological landscape.

Related Models

For those considering the GE FANUC, it's worth exploring these related models that complement its capabilities:

1. **GE IS200TBCIH1BBC** – A dedicated control module ideal for simple automation tasks.

2. **GE IS220PPROS1B** – Offers advanced processing capabilities for specialized applications.

3. **GE IS215UCVEH2AB** – A versatile controller suitable for both small and large-scale applications.

4. **GE DS200CTBAG1ADD** – Focuses on providing robust communication features for distributed systems.

5. **GE HE693STP110** – A powerful solution for high-speed processing and control.

6. **GE IC660ELB912G** – Tailored for specific I/O requirements in industrial settings.

7. **GE IS200TPROH1BCB** – Designed for high-speed data processing in demanding environments.

8. **GE IC670MDL640** – A modular option for various industrial control tasks.

9. **GE IS200DSPXH1DBC** – Excellent for digital signal processing applications.

10. **GE IC693CPU374** – A highly reliable CPU for complex automation tasks.

In conclusion, the GE FANUC stands as a testament to GE's commitment to innovation in automation technology. With its advanced features, adaptable design, and compatibility with a wide array of applications, it is the ideal choice for businesses seeking to elevate their operational capabilities. Whether you are looking to streamline manufacturing processes, enhance energy management, or implement comprehensive building automation, the GE FANUC provides the performance and reliability that modern industries demand. Embrace the future of automation with GE FANUC and experience unparalleled efficiency and productivity in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the rapidly evolving landscape of industrial automation, the GE FANUC stands out as a robust solution tailored to meet the demands of modern manufacturing and control systems. This model epitomizes innovation, reliability, and high performance, making it an invaluable asset for businesses looking to enhance their operational efficiency.

Key Technical Features

The GE FANUC is designed with cutting-edge technology that ensures seamless integration into various industrial applications. Some of its standout features include:

1. **High-Performance Processing**: Equipped with a powerful microprocessor, the GE FANUC delivers rapid data processing capabilities, enabling real-time monitoring and control of complex systems.

2. **Versatile Communication Protocols**: The GE FANUC supports multiple communication protocols, including Ethernet, ControlNet, and DeviceNet, allowing for flexible integration with existing systems and enhancing interoperability with other devices.

3. **Robust I/O Capabilities**: With a wide range of input and output options, the GE FANUC is capable of handling diverse sensor and actuator configurations, making it suitable for various applications from simple control tasks to complex automation processes.

4. **Scalability**: Designed to grow with your business needs, the GE FANUC can easily be expanded with additional modules, ensuring that your automation system can adapt to changing operational requirements.

5. **User-Friendly Interface**: The GE FANUC features an intuitive interface that simplifies programming and troubleshooting, reducing downtime and enhancing overall productivity.

6. **Advanced Diagnostics**: Built-in diagnostic tools provide real-time feedback on system performance, allowing for proactive maintenance and minimizing unexpected failures.

Usage Scenarios

The versatility of the GE FANUC makes it suitable for a variety of industrial applications. It excels in:

– **Manufacturing Automation**: Streamlining production processes in assembly lines, packaging, and quality control.

– **Process Control**: Monitoring and controlling parameters in industries such as chemicals, pharmaceuticals, and food processing, ensuring optimal conditions and compliance with safety standards.

– **Energy Management**: Enhancing efficiency in energy distribution and management systems, contributing to reduced operational costs and improved sustainability.

– **Building Automation**: Integrating with HVAC, lighting, and security systems to optimize energy usage and improve occupant comfort.

Comparison with Other Models

When compared to other models within the GE automation products portfolio, the GE FANUC distinguishes itself through its balance of performance and flexibility. For instance, while the GE IS200TBCIH1BBC focuses on dedicated control tasks, the FANUC's modular design allows it to cater to a broader range of applications. Likewise, compared to the GE IC697MDL250, which offers specific I/O capabilities, the GE FANUC’s versatility allows it to adapt to various configurations and requirements.

Additionally, models like the GE IS220PAICH2A are excellent for specific applications but may lack the comprehensive communication options that the GE FANUC provides. This makes the FANUC a go-to choice for organizations that prioritize future-proof solutions capable of evolving with their technological landscape.

Related Models

For those considering the GE FANUC, it's worth exploring these related models that complement its capabilities:

1. **GE IS200TBCIH1BBC** – A dedicated control module ideal for simple automation tasks.

2. **GE IS220PPROS1B** – Offers advanced processing capabilities for specialized applications.

3. **GE IS215UCVEH2AB** – A versatile controller suitable for both small and large-scale applications.

4. **GE DS200CTBAG1ADD** – Focuses on providing robust communication features for distributed systems.

5. **GE HE693STP110** – A powerful solution for high-speed processing and control.

6. **GE IC660ELB912G** – Tailored for specific I/O requirements in industrial settings.

7. **GE IS200TPROH1BCB** – Designed for high-speed data processing in demanding environments.

8. **GE IC670MDL640** – A modular option for various industrial control tasks.

9. **GE IS200DSPXH1DBC** – Excellent for digital signal processing applications.

10. **GE IC693CPU374** – A highly reliable CPU for complex automation tasks.

In conclusion, the GE FANUC stands as a testament to GE's commitment to innovation in automation technology. With its advanced features, adaptable design, and compatibility with a wide array of applications, it is the ideal choice for businesses seeking to elevate their operational capabilities. Whether you are looking to streamline manufacturing processes, enhance energy management, or implement comprehensive building automation, the GE FANUC provides the performance and reliability that modern industries demand. Embrace the future of automation with GE FANUC and experience unparalleled efficiency and productivity in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.