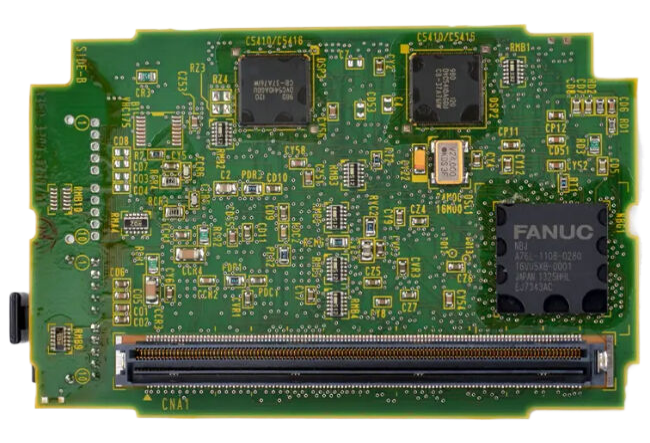

GE Fanuc IC660BBD025 A Cutting-Edge I/O Block for Enhanced Process Control

Introducing the GE Fanuc: The Pinnacle of Industrial Automation

In the realm of industrial automation, the GE Fanuc stands out as a robust and versatile solution designed to enhance operational efficiency and streamline processes. Renowned for its reliability and innovative technology, this model integrates seamlessly with existing systems, making it an essential component in various manufacturing environments.

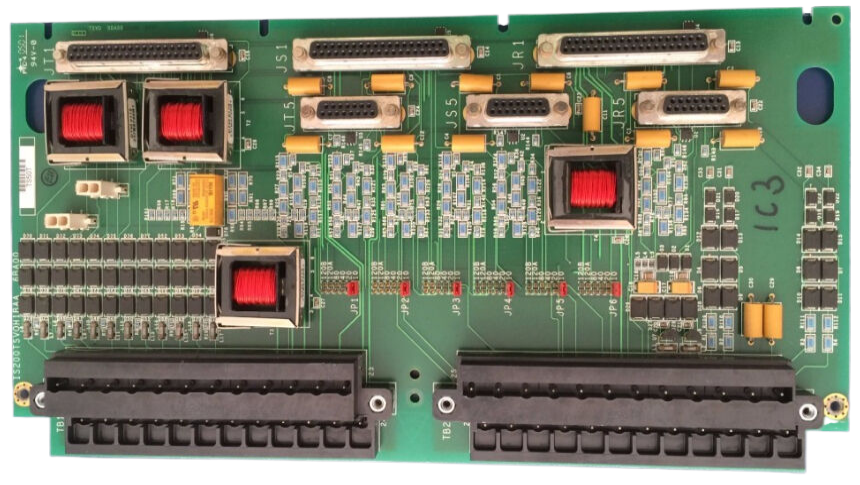

Key Technical Features

The GE Fanuc is engineered with a host of advanced features that set it apart from competitors. At the core of its performance is a powerful processor that ensures rapid data processing and response times, critical for real-time applications. With support for multiple communication protocols, including Ethernet, Serial, and Fieldbus options, this model facilitates seamless connectivity with other GE automation products and third-party devices alike.

The GE Fanuc boasts an expansive I/O capability, allowing for the integration of a wide range of sensors and actuators. This flexibility enables users to customize their automation solutions to meet specific operational demands. Additionally, the unit is equipped with built-in diagnostic tools that provide real-time insights into system performance, enabling proactive maintenance and reducing downtime.

Notably, the GE Fanuc supports advanced programming languages such as Ladder Logic, Structured Text, and Function Block Diagrams, allowing engineers to implement complex control strategies with ease. Its user-friendly interface simplifies the programming process, making it accessible even to those who may not possess extensive programming knowledge.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for a myriad of applications across various industries. In manufacturing, it can be employed for process control, assembly line automation, and equipment monitoring, significantly improving productivity and accuracy. Its ability to handle complex algorithms and control multiple axes makes it a preferred choice in robotics applications, where precision and reliability are paramount.

In the energy sector, the GE Fanuc is utilized for monitoring and controlling power generation processes, ensuring optimal operation and compliance with safety regulations. It can also be found in water treatment facilities, where it manages pumping stations and treatment processes, enhancing efficiency and reducing operational costs.

The GE Fanuc is not limited to traditional industries; it also finds application in smart buildings and facilities management, where it integrates with HVAC systems, lighting controls, and security systems, contributing to energy conservation and improved user comfort.

Comparison with Other Models

When comparing the GE Fanuc to other models within the GE lineup, such as the GE SR750 and the GE IS200DSPXH2DBD, it becomes evident that the Fanuc offers a superior balance of performance and adaptability. While the SR750 is designed for high-speed applications, it lacks the extensive I/O options that the Fanuc provides, making the latter a more versatile choice for diverse automation needs.

Similarly, the GE IS200DSPXH2DBD excels in specific control tasks but may fall short in terms of communication flexibility compared to the GE Fanuc. The ability of the Fanuc to support multiple protocols and seamlessly integrate with a broader range of devices gives it a competitive edge.

In contrast, the GE IC695CPE310-ABAH offers advanced features tailored for complex applications; however, it may require more extensive configuration and setup time, which could delay deployment. The GE Fanuc, with its user-friendly programming interface, allows for quicker implementation, making it ideal for businesses looking to enhance productivity without extensive training.

Reference to Related Models

For those exploring the breadth of GE automation products, several related models complement the GE Fanuc and expand possibilities within industrial automation. The GE IS200JPDMG1ADC provides advanced motion control capabilities, while the GE DS200DDTBG2A offers robust data acquisition features suitable for various monitoring applications.

The GE IC693ACC302 is another noteworthy model, known for its exceptional connectivity options that work harmoniously with the GE Fanuc. Meanwhile, the GE IS200EDFFH1ABA is a preferred choice for users requiring high-speed data processing in intricate control systems.

In scenarios where precision and control are paramount, the GE IC200CPU005 and the GE IS220PPDAH1A offer excellent alternatives that can integrate effectively with the GE Fanuc, ensuring comprehensive automation solutions.

Additionally, the GE DS200SIOCG1A and the GE VMIVME-7671-421000 are ideal for users looking to expand their I/O capabilities, while the GE IC660BBA020 provides advanced communication options that enhance system interoperability.

In Conclusion

The GE Fanuc embodies the pinnacle of reliability, adaptability, and performance within the GE automation products family. With its extensive feature set, diverse application possibilities, and seamless integration capabilities, it stands as a premier choice for businesses aiming to optimize their automation processes. Whether in manufacturing, energy, or smart building applications, the GE Fanuc is poised to meet the demands of modern industry, setting a new standard in automation excellence. Choose the GE Fanuc and experience the future of industrial automation today.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation, the GE Fanuc stands out as a robust and versatile solution designed to enhance operational efficiency and streamline processes. Renowned for its reliability and innovative technology, this model integrates seamlessly with existing systems, making it an essential component in various manufacturing environments.

Key Technical Features

The GE Fanuc is engineered with a host of advanced features that set it apart from competitors. At the core of its performance is a powerful processor that ensures rapid data processing and response times, critical for real-time applications. With support for multiple communication protocols, including Ethernet, Serial, and Fieldbus options, this model facilitates seamless connectivity with other GE automation products and third-party devices alike.

The GE Fanuc boasts an expansive I/O capability, allowing for the integration of a wide range of sensors and actuators. This flexibility enables users to customize their automation solutions to meet specific operational demands. Additionally, the unit is equipped with built-in diagnostic tools that provide real-time insights into system performance, enabling proactive maintenance and reducing downtime.

Notably, the GE Fanuc supports advanced programming languages such as Ladder Logic, Structured Text, and Function Block Diagrams, allowing engineers to implement complex control strategies with ease. Its user-friendly interface simplifies the programming process, making it accessible even to those who may not possess extensive programming knowledge.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for a myriad of applications across various industries. In manufacturing, it can be employed for process control, assembly line automation, and equipment monitoring, significantly improving productivity and accuracy. Its ability to handle complex algorithms and control multiple axes makes it a preferred choice in robotics applications, where precision and reliability are paramount.

In the energy sector, the GE Fanuc is utilized for monitoring and controlling power generation processes, ensuring optimal operation and compliance with safety regulations. It can also be found in water treatment facilities, where it manages pumping stations and treatment processes, enhancing efficiency and reducing operational costs.

The GE Fanuc is not limited to traditional industries; it also finds application in smart buildings and facilities management, where it integrates with HVAC systems, lighting controls, and security systems, contributing to energy conservation and improved user comfort.

Comparison with Other Models

When comparing the GE Fanuc to other models within the GE lineup, such as the GE SR750 and the GE IS200DSPXH2DBD, it becomes evident that the Fanuc offers a superior balance of performance and adaptability. While the SR750 is designed for high-speed applications, it lacks the extensive I/O options that the Fanuc provides, making the latter a more versatile choice for diverse automation needs.

Similarly, the GE IS200DSPXH2DBD excels in specific control tasks but may fall short in terms of communication flexibility compared to the GE Fanuc. The ability of the Fanuc to support multiple protocols and seamlessly integrate with a broader range of devices gives it a competitive edge.

In contrast, the GE IC695CPE310-ABAH offers advanced features tailored for complex applications; however, it may require more extensive configuration and setup time, which could delay deployment. The GE Fanuc, with its user-friendly programming interface, allows for quicker implementation, making it ideal for businesses looking to enhance productivity without extensive training.

Reference to Related Models

For those exploring the breadth of GE automation products, several related models complement the GE Fanuc and expand possibilities within industrial automation. The GE IS200JPDMG1ADC provides advanced motion control capabilities, while the GE DS200DDTBG2A offers robust data acquisition features suitable for various monitoring applications.

The GE IC693ACC302 is another noteworthy model, known for its exceptional connectivity options that work harmoniously with the GE Fanuc. Meanwhile, the GE IS200EDFFH1ABA is a preferred choice for users requiring high-speed data processing in intricate control systems.

In scenarios where precision and control are paramount, the GE IC200CPU005 and the GE IS220PPDAH1A offer excellent alternatives that can integrate effectively with the GE Fanuc, ensuring comprehensive automation solutions.

Additionally, the GE DS200SIOCG1A and the GE VMIVME-7671-421000 are ideal for users looking to expand their I/O capabilities, while the GE IC660BBA020 provides advanced communication options that enhance system interoperability.

In Conclusion

The GE Fanuc embodies the pinnacle of reliability, adaptability, and performance within the GE automation products family. With its extensive feature set, diverse application possibilities, and seamless integration capabilities, it stands as a premier choice for businesses aiming to optimize their automation processes. Whether in manufacturing, energy, or smart building applications, the GE Fanuc is poised to meet the demands of modern industry, setting a new standard in automation excellence. Choose the GE Fanuc and experience the future of industrial automation today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.