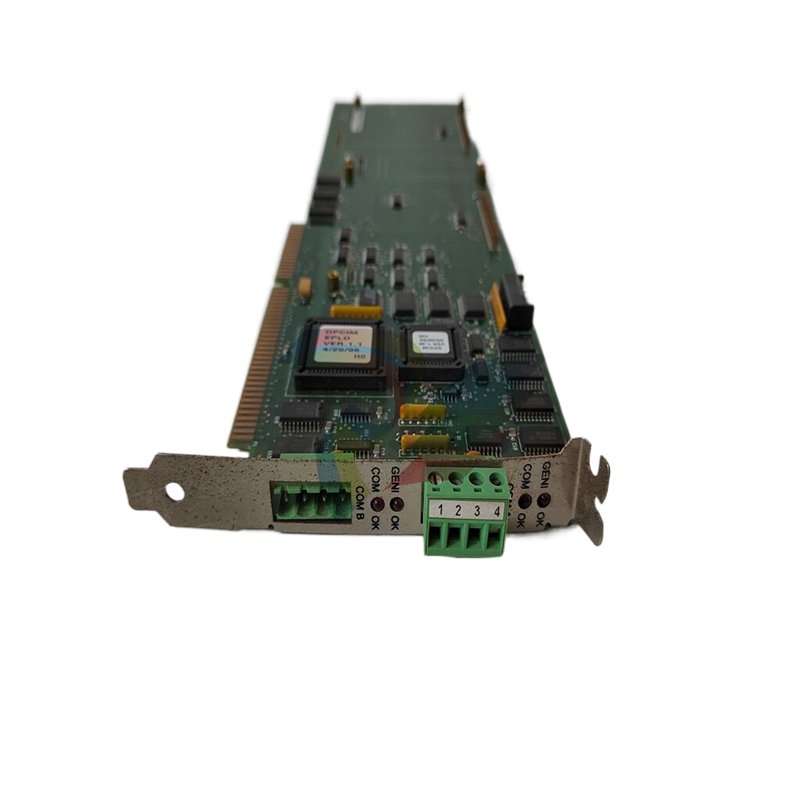

GE Fanuc IC660ELB906R Advanced I/O Controller for Industrial Automation

Introducing the GE Fanuc Model: A Pinnacle of Precision and Reliability in Automation

The GE Fanuc model stands as a testament to the advanced engineering and innovative technology that GE has long been known for in the field of industrial automation. With a robust design and a suite of key technical features, the GE Fanuc model is engineered to cater to the diverse needs of modern manufacturing environments. It is a reliable choice for organizations looking to enhance their automation processes, ensuring efficiency and optimal performance.

Key Technical Features

The GE Fanuc model is equipped with a number of cutting-edge technical features that make it stand out in the competitive landscape of automation products. Among its highlights are:

1. **High Processing Speed**: The GE Fanuc model boasts a high-speed processor that can handle complex computations and data processing tasks effortlessly. This ensures that operations run smoothly without delays, even in high-demand environments.

2. **Versatile I/O Compatibility**: Designed with versatility in mind, the GE Fanuc model supports a wide range of input and output modules. This compatibility allows for seamless integration into existing systems, providing flexibility to adapt to various industrial applications.

3. **Robust Communication Protocols**: The model features multiple communication protocols, including Ethernet, Modbus, and Profibus, facilitating easy connectivity with other devices and systems. This ensures that data can be shared efficiently across the production floor.

4. **User-Friendly Interface**: The intuitive user interface simplifies operation and programming, reducing the learning curve for new users. This feature is particularly beneficial in environments where quick adaptation to technology is crucial.

5. **Scalability**: The GE Fanuc model is designed to grow with your business. Its modular architecture allows for easy expansion, ensuring that as your operational needs increase, your automation system can be upgraded without significant overhauls.

Usage Scenarios

The GE Fanuc model finds its applications in a wide variety of industrial settings, making it an essential asset for businesses looking to streamline their processes. Here are some common usage scenarios:

1. **Manufacturing Automation**: In manufacturing facilities, the GE Fanuc model can control assembly lines, monitor production processes, and manage robotic systems, enhancing overall productivity and reducing downtime.

2. **Process Control**: Industries such as oil and gas, pharmaceuticals, and food processing leverage the GE Fanuc model for precise control of critical processes. Its ability to handle multiple inputs and outputs simultaneously ensures optimal performance in demanding environments.

3. **Data Acquisition**: The model excels in data acquisition applications where real-time monitoring and data logging are essential. It can collect and analyze data from various sensors, enabling businesses to make informed decisions based on accurate information.

4. **SCADA Systems**: The GE Fanuc model is a key component in Supervisory Control and Data Acquisition (SCADA) systems. Its robust communication capabilities allow it to gather and process data from remote locations, providing a comprehensive view of operations.

Comparison with Other Models

When comparing the GE Fanuc model to other models within the GE lineup, such as the GE SR750 or the GE IC697MDL740, several distinctions emerge. While the GE SR750 is optimized for simpler applications with less processing power, the GE Fanuc model offers enhanced speed and versatility, making it better suited for complex automation tasks. Alternatively, the GE IC697MDL740 excels in high-density applications, but it may lack some of the advanced communication features present in the GE Fanuc model.

In contrast to models like the GE IS200DSPXH2DBD or GE DS200DDTBG2A, which are tailored for specific applications, the GE Fanuc model provides a more universal solution applicable across various sectors. Its scalability and adaptability position it as a superior choice for organizations anticipating growth or diversification in their operations.

Related Models

The GE Fanuc model is part of a broader ecosystem of GE automation products, each designed to meet specific operational needs. Here are ten related models that complement the capabilities of the GE Fanuc:

1. **GE SR750**: Ideal for entry-level applications with basic automation needs.

2. **GE IC697MDL740**: A versatile module suitable for various I/O requirements.

3. **GE IS200DSFCG1AEB**: Designed for advanced control applications.

4. **GE IC660BBA020**: An excellent choice for high-density I/O configurations.

5. **GE DS200DDTBG2A**: Tailored for data transfer and communication tasks.

6. **GE IS200DSPXH2DBD**: Focused on digital signal processing applications.

7. **GE IS220PPDAH1A**: A powerful processor for enhanced processing capabilities.

8. **GE IC693APU301**: A robust unit for power supply applications.

9. **GE IC200CPU005**: A compact PLC for smaller automation tasks.

10. **GE IC695CPE310-ABAH**: Offers advanced control capabilities for large-scale operations.

SEO Keywords Integration

In the realm of industrial automation, the GE Fanuc model exemplifies innovation and reliability. As part of the renowned GE automation products line, it is engineered to address the evolving needs of various industries. By incorporating advanced features, versatile applications, and seamless integration capabilities, the GE Fanuc model stands at the forefront of automation technology, making it a preferred choice for companies aiming to enhance operational efficiency.

In conclusion, the GE Fanuc model not only meets the demands of modern automation but also sets the standard for excellence in the industry. Whether you are looking to upgrade your existing systems or invest in new automation technology, the GE Fanuc model is a robust and versatile solution that will elevate your operational capabilities. Embrace the future of automation with GE Fanuc – where precision meets performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE Fanuc model stands as a testament to the advanced engineering and innovative technology that GE has long been known for in the field of industrial automation. With a robust design and a suite of key technical features, the GE Fanuc model is engineered to cater to the diverse needs of modern manufacturing environments. It is a reliable choice for organizations looking to enhance their automation processes, ensuring efficiency and optimal performance.

Key Technical Features

The GE Fanuc model is equipped with a number of cutting-edge technical features that make it stand out in the competitive landscape of automation products. Among its highlights are:

1. **High Processing Speed**: The GE Fanuc model boasts a high-speed processor that can handle complex computations and data processing tasks effortlessly. This ensures that operations run smoothly without delays, even in high-demand environments.

2. **Versatile I/O Compatibility**: Designed with versatility in mind, the GE Fanuc model supports a wide range of input and output modules. This compatibility allows for seamless integration into existing systems, providing flexibility to adapt to various industrial applications.

3. **Robust Communication Protocols**: The model features multiple communication protocols, including Ethernet, Modbus, and Profibus, facilitating easy connectivity with other devices and systems. This ensures that data can be shared efficiently across the production floor.

4. **User-Friendly Interface**: The intuitive user interface simplifies operation and programming, reducing the learning curve for new users. This feature is particularly beneficial in environments where quick adaptation to technology is crucial.

5. **Scalability**: The GE Fanuc model is designed to grow with your business. Its modular architecture allows for easy expansion, ensuring that as your operational needs increase, your automation system can be upgraded without significant overhauls.

Usage Scenarios

The GE Fanuc model finds its applications in a wide variety of industrial settings, making it an essential asset for businesses looking to streamline their processes. Here are some common usage scenarios:

1. **Manufacturing Automation**: In manufacturing facilities, the GE Fanuc model can control assembly lines, monitor production processes, and manage robotic systems, enhancing overall productivity and reducing downtime.

2. **Process Control**: Industries such as oil and gas, pharmaceuticals, and food processing leverage the GE Fanuc model for precise control of critical processes. Its ability to handle multiple inputs and outputs simultaneously ensures optimal performance in demanding environments.

3. **Data Acquisition**: The model excels in data acquisition applications where real-time monitoring and data logging are essential. It can collect and analyze data from various sensors, enabling businesses to make informed decisions based on accurate information.

4. **SCADA Systems**: The GE Fanuc model is a key component in Supervisory Control and Data Acquisition (SCADA) systems. Its robust communication capabilities allow it to gather and process data from remote locations, providing a comprehensive view of operations.

Comparison with Other Models

When comparing the GE Fanuc model to other models within the GE lineup, such as the GE SR750 or the GE IC697MDL740, several distinctions emerge. While the GE SR750 is optimized for simpler applications with less processing power, the GE Fanuc model offers enhanced speed and versatility, making it better suited for complex automation tasks. Alternatively, the GE IC697MDL740 excels in high-density applications, but it may lack some of the advanced communication features present in the GE Fanuc model.

In contrast to models like the GE IS200DSPXH2DBD or GE DS200DDTBG2A, which are tailored for specific applications, the GE Fanuc model provides a more universal solution applicable across various sectors. Its scalability and adaptability position it as a superior choice for organizations anticipating growth or diversification in their operations.

Related Models

The GE Fanuc model is part of a broader ecosystem of GE automation products, each designed to meet specific operational needs. Here are ten related models that complement the capabilities of the GE Fanuc:

1. **GE SR750**: Ideal for entry-level applications with basic automation needs.

2. **GE IC697MDL740**: A versatile module suitable for various I/O requirements.

3. **GE IS200DSFCG1AEB**: Designed for advanced control applications.

4. **GE IC660BBA020**: An excellent choice for high-density I/O configurations.

5. **GE DS200DDTBG2A**: Tailored for data transfer and communication tasks.

6. **GE IS200DSPXH2DBD**: Focused on digital signal processing applications.

7. **GE IS220PPDAH1A**: A powerful processor for enhanced processing capabilities.

8. **GE IC693APU301**: A robust unit for power supply applications.

9. **GE IC200CPU005**: A compact PLC for smaller automation tasks.

10. **GE IC695CPE310-ABAH**: Offers advanced control capabilities for large-scale operations.

SEO Keywords Integration

In the realm of industrial automation, the GE Fanuc model exemplifies innovation and reliability. As part of the renowned GE automation products line, it is engineered to address the evolving needs of various industries. By incorporating advanced features, versatile applications, and seamless integration capabilities, the GE Fanuc model stands at the forefront of automation technology, making it a preferred choice for companies aiming to enhance operational efficiency.

In conclusion, the GE Fanuc model not only meets the demands of modern automation but also sets the standard for excellence in the industry. Whether you are looking to upgrade your existing systems or invest in new automation technology, the GE Fanuc model is a robust and versatile solution that will elevate your operational capabilities. Embrace the future of automation with GE Fanuc – where precision meets performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.