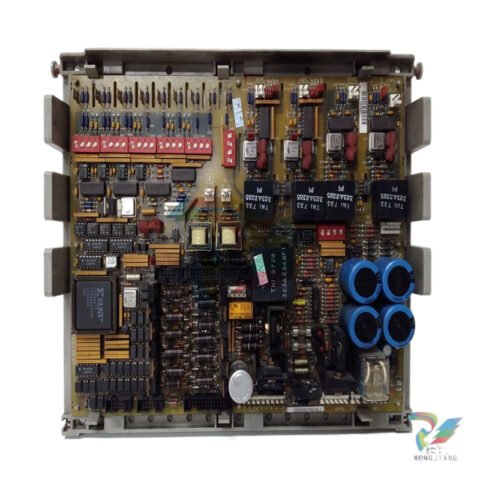

GE Fanuc IC660HHM501N Advanced Hand-Held Monitor for Industrial Control Systems

Introducing the GE Fanuc: A Pinnacle of Automation Excellence

In the world of industrial automation, the GE Fanuc stands out as a sophisticated and reliable solution designed to meet the diverse needs of modern manufacturing. With its robust architecture and cutting-edge features, this model is engineered to enhance productivity and improve operational efficiency across various applications.

Key Technical Features

The GE Fanuc boasts an impressive array of technical specifications that make it a leader in the field of automation products. One of its standout features is its powerful processing capability, which allows for rapid data handling and real-time control. The system is built on a versatile platform that supports multiple programming languages, enabling seamless integration with existing control systems.

The GE Fanuc incorporates advanced communication protocols, ensuring compatibility with a wide range of devices and systems. This feature is essential for manufacturers looking to streamline operations and reduce downtime. Furthermore, its modular design allows for easy scalability, enabling users to expand their systems as needed without significant reconfiguration.

Another key feature is its robust diagnostic capabilities. The GE Fanuc includes built-in self-monitoring systems that provide real-time feedback on performance and health, allowing for proactive maintenance and minimizing unplanned outages. Additionally, the device is designed to operate in harsh environments, with enhanced durability and resistance to temperature fluctuations, dust, and moisture.

Usage Scenarios

The GE Fanuc is versatile and can be utilized across various industries, including automotive, food and beverage, pharmaceuticals, and energy. In automotive manufacturing, for instance, the GE Fanuc can control robotic arms for assembly lines, optimizing precision and speed in vehicle production. In the food and beverage sector, it can manage processing lines, ensuring compliance with safety standards while maximizing throughput.

In pharmaceutical manufacturing, the GE Fanuc plays a crucial role in monitoring and controlling sensitive processes, ensuring that products are consistently produced to the highest quality standards. Moreover, in the energy sector, it can be deployed in power generation and distribution systems, effectively monitoring grid stability and efficiency.

Comparison with Other Models

When comparing the GE Fanuc with other models in the GE product line, such as the GE SR750 or GE IC693APU301, it becomes clear that each model serves distinct purposes while sharing a common commitment to quality and reliability. The GE SR750, for instance, is optimized for high-speed data processing, while the GE IC693APU301 is tailored for applications requiring extensive analog input/output capabilities.

The GE Fanuc, however, strikes a balance between processing power and versatility, making it suitable for a broader range of applications. It also stands out in terms of its modular design, allowing users the flexibility to tailor their systems based on specific operational requirements — a feature that may not be as pronounced in some other models, such as the GE IS200DSPXH2DBD, which is more specialized.

Furthermore, the GE Fanuc can be compared to the GE IC695CPE310-ABAH, which is known for its extensive communication options. While both models offer strong networking capabilities, the GE Fanuc is often favored for its enhanced processing power and ease of integration with existing systems.

Related Models

The GE Fanuc is part of a comprehensive lineup of GE automation products, including:

1. GE SR750 – Known for its high-speed data handling and processing.

2. GE IC697MDL740 – A versatile I/O module designed for various applications.

3. GE IS200DSFCG1AEB – A controller tailored for specific industrial processes.

4. GE IC660BBA020 – A base communication module that enhances network connectivity.

5. GE DS200DDTBG2A – A digital input module that complements the GE Fanuc.

6. GE IS200DSPXH2DBD – A signal processor optimized for complex control tasks.

7. GE IS220PPDAH1A – A power distribution module that works harmoniously with the GE Fanuc.

8. GE IC693ACC302 – An analog input/output module designed for data acquisition.

9. GE IS200JPDMG1ADC – A dual-port communication module for robust networking.

10. GE IC695LRE001B – A relay module that enhances system control capabilities.

When selecting an automation solution, understanding the compatibility and strengths of these related models can help users tailor their systems to achieve optimal performance.

Conclusion

The GE Fanuc represents a culmination of advanced technology, reliability, and flexibility within the realm of industrial automation. Its robust features cater to a wide array of industries, making it a preferred choice for manufacturers seeking to enhance productivity and streamline operations. By leveraging its powerful processing capabilities, extensive communication options, and user-friendly design, the GE Fanuc empowers businesses to achieve their automation goals while ensuring maximum efficiency and minimal downtime.

In an era where industrial automation is pivotal for competitive advantage, the GE Fanuc stands out as a cornerstone of innovation within GE automation products. This model not only meets the demands of today’s manufacturing landscape but also prepares businesses for the challenges of tomorrow. Embrace the future of automation with the GE Fanuc—where reliability meets performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation, the GE Fanuc stands out as a sophisticated and reliable solution designed to meet the diverse needs of modern manufacturing. With its robust architecture and cutting-edge features, this model is engineered to enhance productivity and improve operational efficiency across various applications.

Key Technical Features

The GE Fanuc boasts an impressive array of technical specifications that make it a leader in the field of automation products. One of its standout features is its powerful processing capability, which allows for rapid data handling and real-time control. The system is built on a versatile platform that supports multiple programming languages, enabling seamless integration with existing control systems.

The GE Fanuc incorporates advanced communication protocols, ensuring compatibility with a wide range of devices and systems. This feature is essential for manufacturers looking to streamline operations and reduce downtime. Furthermore, its modular design allows for easy scalability, enabling users to expand their systems as needed without significant reconfiguration.

Another key feature is its robust diagnostic capabilities. The GE Fanuc includes built-in self-monitoring systems that provide real-time feedback on performance and health, allowing for proactive maintenance and minimizing unplanned outages. Additionally, the device is designed to operate in harsh environments, with enhanced durability and resistance to temperature fluctuations, dust, and moisture.

Usage Scenarios

The GE Fanuc is versatile and can be utilized across various industries, including automotive, food and beverage, pharmaceuticals, and energy. In automotive manufacturing, for instance, the GE Fanuc can control robotic arms for assembly lines, optimizing precision and speed in vehicle production. In the food and beverage sector, it can manage processing lines, ensuring compliance with safety standards while maximizing throughput.

In pharmaceutical manufacturing, the GE Fanuc plays a crucial role in monitoring and controlling sensitive processes, ensuring that products are consistently produced to the highest quality standards. Moreover, in the energy sector, it can be deployed in power generation and distribution systems, effectively monitoring grid stability and efficiency.

Comparison with Other Models

When comparing the GE Fanuc with other models in the GE product line, such as the GE SR750 or GE IC693APU301, it becomes clear that each model serves distinct purposes while sharing a common commitment to quality and reliability. The GE SR750, for instance, is optimized for high-speed data processing, while the GE IC693APU301 is tailored for applications requiring extensive analog input/output capabilities.

The GE Fanuc, however, strikes a balance between processing power and versatility, making it suitable for a broader range of applications. It also stands out in terms of its modular design, allowing users the flexibility to tailor their systems based on specific operational requirements — a feature that may not be as pronounced in some other models, such as the GE IS200DSPXH2DBD, which is more specialized.

Furthermore, the GE Fanuc can be compared to the GE IC695CPE310-ABAH, which is known for its extensive communication options. While both models offer strong networking capabilities, the GE Fanuc is often favored for its enhanced processing power and ease of integration with existing systems.

Related Models

The GE Fanuc is part of a comprehensive lineup of GE automation products, including:

1. GE SR750 – Known for its high-speed data handling and processing.

2. GE IC697MDL740 – A versatile I/O module designed for various applications.

3. GE IS200DSFCG1AEB – A controller tailored for specific industrial processes.

4. GE IC660BBA020 – A base communication module that enhances network connectivity.

5. GE DS200DDTBG2A – A digital input module that complements the GE Fanuc.

6. GE IS200DSPXH2DBD – A signal processor optimized for complex control tasks.

7. GE IS220PPDAH1A – A power distribution module that works harmoniously with the GE Fanuc.

8. GE IC693ACC302 – An analog input/output module designed for data acquisition.

9. GE IS200JPDMG1ADC – A dual-port communication module for robust networking.

10. GE IC695LRE001B – A relay module that enhances system control capabilities.

When selecting an automation solution, understanding the compatibility and strengths of these related models can help users tailor their systems to achieve optimal performance.

Conclusion

The GE Fanuc represents a culmination of advanced technology, reliability, and flexibility within the realm of industrial automation. Its robust features cater to a wide array of industries, making it a preferred choice for manufacturers seeking to enhance productivity and streamline operations. By leveraging its powerful processing capabilities, extensive communication options, and user-friendly design, the GE Fanuc empowers businesses to achieve their automation goals while ensuring maximum efficiency and minimal downtime.

In an era where industrial automation is pivotal for competitive advantage, the GE Fanuc stands out as a cornerstone of innovation within GE automation products. This model not only meets the demands of today’s manufacturing landscape but also prepares businesses for the challenges of tomorrow. Embrace the future of automation with the GE Fanuc—where reliability meets performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.