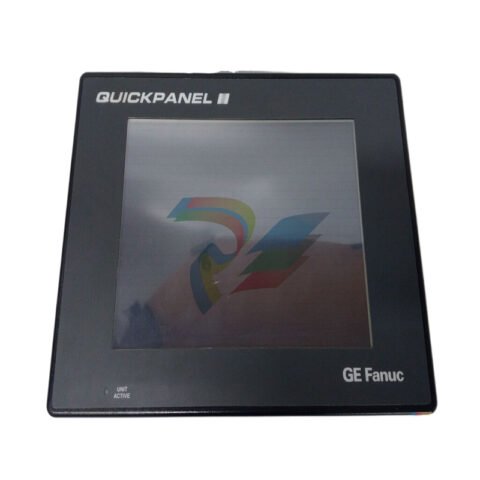

GE Fanuc IC695CHS007 Universal Control Base

Introducing the GE Fanuc – a pinnacle of technology designed for optimal performance in industrial automation. The GE Fanuc series is engineered to meet the high demands of modern manufacturing, providing reliable solutions that enhance productivity and efficiency.

**Key Technical Features:**

The GE Fanuc model boasts an impressive array of technical specifications, making it a standout in the realm of automation products. Key features include:

1. **Robust Processing Power:** Equipped with a high-speed processor, the GE Fanuc ensures rapid data acquisition and processing, allowing for real-time decision-making in complex environments.

2. **Versatile Communication Protocols:** The GE Fanuc supports multiple communication protocols including Ethernet/IP, Modbus, and Profibus, ensuring seamless integration with existing systems and facilitating communication across various devices.

3. **Scalability:** This model is designed with scalability in mind, allowing users to easily expand their automation systems as their needs evolve. Its modular architecture supports additional I/O modules, enabling the customization of setups for specific applications.

4. **User-Friendly Interface:** With an intuitive user interface and advanced software tools, the GE Fanuc simplifies programming and monitoring processes, empowering operators to manage systems with ease.

5. **Durability and Reliability:** Built to withstand harsh industrial environments, the GE Fanuc features rugged construction and protective enclosures that ensure long-term operation with minimal downtime.

6. **Comprehensive Diagnostics:** Advanced diagnostic capabilities provide real-time insights into system performance, helping to preempt issues before they become critical and ensuring optimal operation.

**Usage Scenarios:**

The GE Fanuc is versatile enough to be utilized in a variety of industrial settings. It serves as an ideal solution for:

– **Manufacturing Automation:** Streamlining production lines by automating processes such as assembly, material handling, and quality control, thus minimizing human error and maximizing efficiency.

– **Process Control:** In industries such as oil and gas, pharmaceuticals, and food processing, the GE Fanuc can monitor and control processes with precision, ensuring compliance with safety and quality standards.

– **Building Management Systems:** The model can be integrated into smart building solutions, managing HVAC systems, lighting, and security to enhance energy efficiency and occupant comfort.

– **Logistics and Supply Chain Management:** Enhancing warehouse operations with automation of inventory tracking and order fulfillment, the GE Fanuc optimizes workflow and reduces operational costs.

**Comparison with Other Models:**

When compared to other models within the GE automation products lineup, the GE Fanuc stands out due to its advanced processing capabilities and extensive communication options. For instance, the GE IS200TBCIH1BBC offers specialized functions for turbine control, while the GE IS220PPROS1B is tailored for process control applications.

The GE CT7P70500470CW24, while robust, lacks the scalability features found in the GE Fanuc, making the latter a more flexible choice for companies anticipating growth. The GE IS215UCVEH2AB and GE IS200TPROH1BBC also serve specific niches, but the GE Fanuc’s broad applicability across industries makes it a more versatile solution for diverse automation needs.

**Related Models:**

For those exploring the GE automation products range, the following models are worth considering:

1. **GE IC697MDL250:** A reliable digital input module for process control applications.

2. **GE IC693CPU374:** A powerful CPU that offers advanced processing capabilities for complex automation tasks.

3. **GE IS200TPROH1BCB:** Ideal for turbine control applications, providing tailored solutions for energy production.

4. **GE IS230SNIDH1A:** A model designed for system monitoring and diagnostics, ensuring optimal performance of industrial systems.

5. **GE IC670MDL740J:** A versatile digital output module suited for various control applications.

6. **GE DS200CTBAG1ADD:** A control board that enhances system performance with advanced features.

7. **GE HE693STP110:** A high-performance stepper motor control module for precise motion applications.

8. **GE IS215UCVEH2AB:** A universal control module that offers flexible solutions for various industrial applications.

9. **GE IS200DSPXH1DBC:** A digital signal processor tailored for high-speed data processing tasks.

10. **GE IS200EPSMG2ADC:** An electronic control system that manages power distribution effectively within industrial settings.

**Conclusion:**

In summary, the GE Fanuc model represents a harmonious blend of cutting-edge technology, reliability, and versatility, making it an essential component in the landscape of industrial automation. Whether you are looking to enhance manufacturing efficiency, improve process control, or streamline building management, the GE Fanuc delivers exceptional performance that meets the diverse needs of modern industries.

As you explore the world of GE automation products, consider the GE Fanuc for its unparalleled capabilities and adaptability, ensuring that your operations are not just automated but optimized for success.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features:**

The GE Fanuc model boasts an impressive array of technical specifications, making it a standout in the realm of automation products. Key features include:

1. **Robust Processing Power:** Equipped with a high-speed processor, the GE Fanuc ensures rapid data acquisition and processing, allowing for real-time decision-making in complex environments.

2. **Versatile Communication Protocols:** The GE Fanuc supports multiple communication protocols including Ethernet/IP, Modbus, and Profibus, ensuring seamless integration with existing systems and facilitating communication across various devices.

3. **Scalability:** This model is designed with scalability in mind, allowing users to easily expand their automation systems as their needs evolve. Its modular architecture supports additional I/O modules, enabling the customization of setups for specific applications.

4. **User-Friendly Interface:** With an intuitive user interface and advanced software tools, the GE Fanuc simplifies programming and monitoring processes, empowering operators to manage systems with ease.

5. **Durability and Reliability:** Built to withstand harsh industrial environments, the GE Fanuc features rugged construction and protective enclosures that ensure long-term operation with minimal downtime.

6. **Comprehensive Diagnostics:** Advanced diagnostic capabilities provide real-time insights into system performance, helping to preempt issues before they become critical and ensuring optimal operation.

**Usage Scenarios:**

The GE Fanuc is versatile enough to be utilized in a variety of industrial settings. It serves as an ideal solution for:

– **Manufacturing Automation:** Streamlining production lines by automating processes such as assembly, material handling, and quality control, thus minimizing human error and maximizing efficiency.

– **Process Control:** In industries such as oil and gas, pharmaceuticals, and food processing, the GE Fanuc can monitor and control processes with precision, ensuring compliance with safety and quality standards.

– **Building Management Systems:** The model can be integrated into smart building solutions, managing HVAC systems, lighting, and security to enhance energy efficiency and occupant comfort.

– **Logistics and Supply Chain Management:** Enhancing warehouse operations with automation of inventory tracking and order fulfillment, the GE Fanuc optimizes workflow and reduces operational costs.

**Comparison with Other Models:**

When compared to other models within the GE automation products lineup, the GE Fanuc stands out due to its advanced processing capabilities and extensive communication options. For instance, the GE IS200TBCIH1BBC offers specialized functions for turbine control, while the GE IS220PPROS1B is tailored for process control applications.

The GE CT7P70500470CW24, while robust, lacks the scalability features found in the GE Fanuc, making the latter a more flexible choice for companies anticipating growth. The GE IS215UCVEH2AB and GE IS200TPROH1BBC also serve specific niches, but the GE Fanuc’s broad applicability across industries makes it a more versatile solution for diverse automation needs.

**Related Models:**

For those exploring the GE automation products range, the following models are worth considering:

1. **GE IC697MDL250:** A reliable digital input module for process control applications.

2. **GE IC693CPU374:** A powerful CPU that offers advanced processing capabilities for complex automation tasks.

3. **GE IS200TPROH1BCB:** Ideal for turbine control applications, providing tailored solutions for energy production.

4. **GE IS230SNIDH1A:** A model designed for system monitoring and diagnostics, ensuring optimal performance of industrial systems.

5. **GE IC670MDL740J:** A versatile digital output module suited for various control applications.

6. **GE DS200CTBAG1ADD:** A control board that enhances system performance with advanced features.

7. **GE HE693STP110:** A high-performance stepper motor control module for precise motion applications.

8. **GE IS215UCVEH2AB:** A universal control module that offers flexible solutions for various industrial applications.

9. **GE IS200DSPXH1DBC:** A digital signal processor tailored for high-speed data processing tasks.

10. **GE IS200EPSMG2ADC:** An electronic control system that manages power distribution effectively within industrial settings.

**Conclusion:**

In summary, the GE Fanuc model represents a harmonious blend of cutting-edge technology, reliability, and versatility, making it an essential component in the landscape of industrial automation. Whether you are looking to enhance manufacturing efficiency, improve process control, or streamline building management, the GE Fanuc delivers exceptional performance that meets the diverse needs of modern industries.

As you explore the world of GE automation products, consider the GE Fanuc for its unparalleled capabilities and adaptability, ensuring that your operations are not just automated but optimized for success.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.