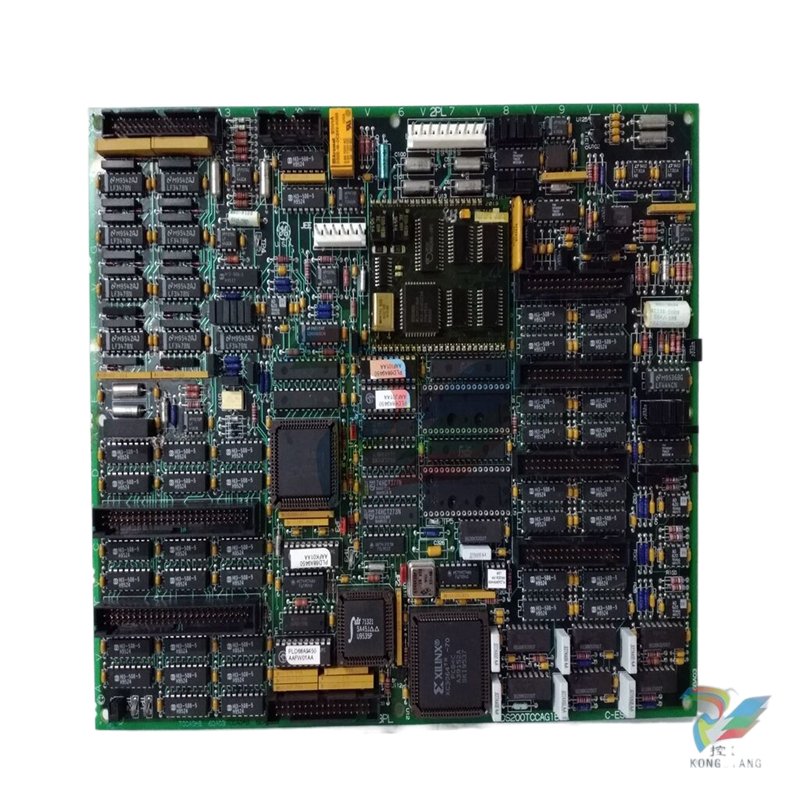

GE FANUC IC754-VSI06MTD QuickPanel Control Advanced Industrial HMI Solution

Introducing the GE FANUC series, a pinnacle of innovation in the realm of industrial automation. GE's commitment to quality and performance is embodied in the FANUC line, designed to meet the stringent demands of modern manufacturing environments and enhance operational efficiency. In this comprehensive product description, we will delve into the key technical features of the GE FANUC models, explore their diverse usage scenarios, compare them with other models, and highlight related products that complement this exceptional range of GE automation products.

Key Technical Features

The GE FANUC series stands out for its robust design and advanced functionalities that cater to a variety of industrial applications. Key technical features include:

1. **Versatile Communication Protocols**: GE FANUC products support multiple communication protocols, including Ethernet/IP, Modbus TCP/IP, and PROFIBUS, allowing seamless integration with existing systems and ensuring compatibility across diverse platforms.

2. **High Processing Power**: Engineered with powerful processors, GE FANUC models deliver rapid data processing capabilities, enabling real-time monitoring and control of manufacturing processes. This high-performance architecture is ideal for demanding applications that require timely decision-making.

3. **Scalability**: The modular structure of the GE FANUC series allows for easy scalability, enabling businesses to expand their systems as needed without significant overhauls. This adaptability makes it suitable for both small-scale operations and large industrial plants.

4. **Robust Memory Options**: These products come equipped with substantial memory capacities, facilitating extensive data logging and the ability to handle complex applications. This feature is essential for industries that rely on extensive data analysis for operational insights.

5. **User-Friendly Interface**: The intuitive interfaces of GE FANUC products simplify setup and operation. Operators can easily navigate through the system, enhancing productivity and reducing training time.

6. **Durability and Reliability**: Built to withstand harsh industrial environments, these models feature rugged housings and components that ensure longevity and minimal downtime, contributing to a more efficient manufacturing process.

Usage Scenarios

GE FANUC products are versatile and can be employed in a wide range of applications across various industries. Some common usage scenarios include:

1. **Manufacturing Automation**: In manufacturing settings, GE FANUC systems are utilized for process control, machine monitoring, and production line optimization. They help streamline operations, reduce waste, and enhance overall productivity.

2. **Energy Management**: These systems play a critical role in energy management, allowing businesses to monitor energy consumption in real-time, optimize energy usage, and implement strategies for sustainability.

3. **Transportation Systems**: GE FANUC technology is employed in transportation systems for traffic management and control, ensuring efficient flow and contributing to enhanced safety measures.

4. **Oil and Gas Industry**: In the oil and gas sector, GE FANUC models are used for remote monitoring, control of drilling operations, and ensuring compliance with safety regulations.

5. **Water Treatment Facilities**: These systems are integral to water treatment plants, controlling processes, monitoring water quality, and ensuring efficient resource management.

Comparison with Other Models

When comparing GE FANUC products with other models in the GE automation products lineup, several distinctions emerge:

1. **IS200 Series**: While the IS200 series, such as the GE IS200TPROH1BCB, focuses on advanced process control and includes specialized features for specific applications, the GE FANUC series offers a broader range of compatibility with various industrial systems.

2. **IC660 Series**: The IC660 series is known for its extensive I/O capabilities, making it suitable for applications requiring high input-output density. In contrast, GE FANUC products provide a more versatile solution for diverse manufacturing processes.

3. **IC693 Series**: The IC693 series emphasizes high availability and redundancy, catering to mission-critical applications. GE FANUC, while also reliable, focuses more on scalability and adaptability, making it ideal for evolving industrial environments.

4. **IS220 Series**: The IS220 series is designed for specific control tasks with advanced features. However, GE FANUC models excel in their modular design, allowing for greater flexibility and ease of integration.

Related Models

To further enhance your industrial automation capabilities, consider these related models within the GE product lineup:

1. **GE IS200TBCIH1BBC**: A versatile controller ideal for various automation tasks.

2. **GE IS220PPROS1B**: A process controller designed for precise control and monitoring.

3. **GE IS215UCVEH2AB**: A powerful controller for complex automation solutions.

4. **GE DS200CTBAG1ADD**: A reliable unit for control applications in demanding environments.

5. **GE IC670CHS001E**: A communication processor that facilitates data exchange between systems.

6. **GE IS200DSPXH1DBC**: A digital signal processor designed for high-performance applications.

7. **GE IC698CMX016**: A versatile controller suited for a range of industrial applications.

8. **GE IS200TPROH1BBB**: A robust control solution for process automation.

9. **GE IS230SNIDH1A**: A specialized model for network integration and data sharing.

10. **GE IC697MDL250**: An I/O module that complements the FANUC series for expanded functionalities.

Conclusion

The GE FANUC series represents a significant advancement in industrial automation, combining high performance, flexibility, and durability. With a wide array of applications ranging from manufacturing to energy management, these products are designed to optimize operations and improve efficiency. By choosing GE FANUC, businesses can leverage the best of GE automation products to stay competitive in an ever-evolving industrial landscape. Whether integrating with existing systems or embarking on new projects, the GE FANUC series stands ready to meet the challenges of modern industry.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE FANUC series stands out for its robust design and advanced functionalities that cater to a variety of industrial applications. Key technical features include:

1. **Versatile Communication Protocols**: GE FANUC products support multiple communication protocols, including Ethernet/IP, Modbus TCP/IP, and PROFIBUS, allowing seamless integration with existing systems and ensuring compatibility across diverse platforms.

2. **High Processing Power**: Engineered with powerful processors, GE FANUC models deliver rapid data processing capabilities, enabling real-time monitoring and control of manufacturing processes. This high-performance architecture is ideal for demanding applications that require timely decision-making.

3. **Scalability**: The modular structure of the GE FANUC series allows for easy scalability, enabling businesses to expand their systems as needed without significant overhauls. This adaptability makes it suitable for both small-scale operations and large industrial plants.

4. **Robust Memory Options**: These products come equipped with substantial memory capacities, facilitating extensive data logging and the ability to handle complex applications. This feature is essential for industries that rely on extensive data analysis for operational insights.

5. **User-Friendly Interface**: The intuitive interfaces of GE FANUC products simplify setup and operation. Operators can easily navigate through the system, enhancing productivity and reducing training time.

6. **Durability and Reliability**: Built to withstand harsh industrial environments, these models feature rugged housings and components that ensure longevity and minimal downtime, contributing to a more efficient manufacturing process.

Usage Scenarios

GE FANUC products are versatile and can be employed in a wide range of applications across various industries. Some common usage scenarios include:

1. **Manufacturing Automation**: In manufacturing settings, GE FANUC systems are utilized for process control, machine monitoring, and production line optimization. They help streamline operations, reduce waste, and enhance overall productivity.

2. **Energy Management**: These systems play a critical role in energy management, allowing businesses to monitor energy consumption in real-time, optimize energy usage, and implement strategies for sustainability.

3. **Transportation Systems**: GE FANUC technology is employed in transportation systems for traffic management and control, ensuring efficient flow and contributing to enhanced safety measures.

4. **Oil and Gas Industry**: In the oil and gas sector, GE FANUC models are used for remote monitoring, control of drilling operations, and ensuring compliance with safety regulations.

5. **Water Treatment Facilities**: These systems are integral to water treatment plants, controlling processes, monitoring water quality, and ensuring efficient resource management.

Comparison with Other Models

When comparing GE FANUC products with other models in the GE automation products lineup, several distinctions emerge:

1. **IS200 Series**: While the IS200 series, such as the GE IS200TPROH1BCB, focuses on advanced process control and includes specialized features for specific applications, the GE FANUC series offers a broader range of compatibility with various industrial systems.

2. **IC660 Series**: The IC660 series is known for its extensive I/O capabilities, making it suitable for applications requiring high input-output density. In contrast, GE FANUC products provide a more versatile solution for diverse manufacturing processes.

3. **IC693 Series**: The IC693 series emphasizes high availability and redundancy, catering to mission-critical applications. GE FANUC, while also reliable, focuses more on scalability and adaptability, making it ideal for evolving industrial environments.

4. **IS220 Series**: The IS220 series is designed for specific control tasks with advanced features. However, GE FANUC models excel in their modular design, allowing for greater flexibility and ease of integration.

Related Models

To further enhance your industrial automation capabilities, consider these related models within the GE product lineup:

1. **GE IS200TBCIH1BBC**: A versatile controller ideal for various automation tasks.

2. **GE IS220PPROS1B**: A process controller designed for precise control and monitoring.

3. **GE IS215UCVEH2AB**: A powerful controller for complex automation solutions.

4. **GE DS200CTBAG1ADD**: A reliable unit for control applications in demanding environments.

5. **GE IC670CHS001E**: A communication processor that facilitates data exchange between systems.

6. **GE IS200DSPXH1DBC**: A digital signal processor designed for high-performance applications.

7. **GE IC698CMX016**: A versatile controller suited for a range of industrial applications.

8. **GE IS200TPROH1BBB**: A robust control solution for process automation.

9. **GE IS230SNIDH1A**: A specialized model for network integration and data sharing.

10. **GE IC697MDL250**: An I/O module that complements the FANUC series for expanded functionalities.

Conclusion

The GE FANUC series represents a significant advancement in industrial automation, combining high performance, flexibility, and durability. With a wide array of applications ranging from manufacturing to energy management, these products are designed to optimize operations and improve efficiency. By choosing GE FANUC, businesses can leverage the best of GE automation products to stay competitive in an ever-evolving industrial landscape. Whether integrating with existing systems or embarking on new projects, the GE FANUC series stands ready to meet the challenges of modern industry.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.