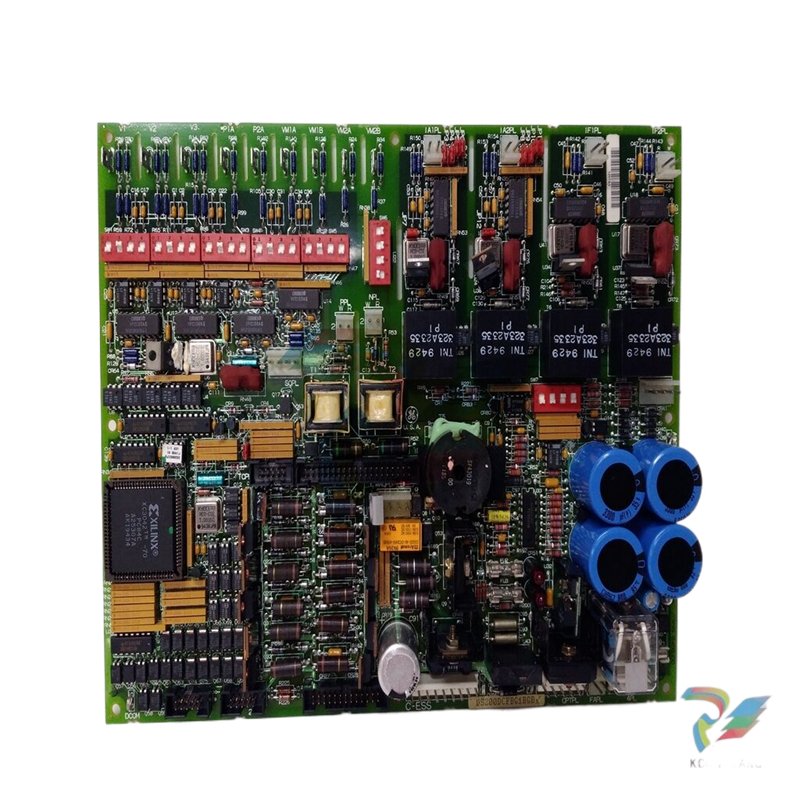

GE Fanuc IS200ECTBG2A Exciter Contact Terminal Board for Simplex Mode

Introducing the GE Fanuc – a leading-edge solution in the realm of automation products that seamlessly integrates advanced technology with unparalleled performance. The GE Fanuc series is engineered for reliability and efficiency, making it an ideal choice for industries seeking to enhance their operational capabilities.

**Key Technical Features**

The GE Fanuc stands out with its robust technical specifications, designed to meet the demanding needs of modern industrial applications. Key features include:

1. **High Processing Power**: The GE Fanuc is equipped with a powerful processor that allows for rapid data processing and real-time control. This capability is crucial for industries that rely on quick decision-making and precise operations.

2. **Versatile Communication Protocols**: Supporting multiple communication protocols, the GE Fanuc ensures seamless integration with various devices and systems. This feature is essential for creating a cohesive automation environment, facilitating easier data exchange and system coordination.

3. **Scalability**: The GE Fanuc is designed to grow with your business. Its modular architecture allows for easy expansion, enabling users to add additional I/O modules, communication options, or processing power as their needs evolve.

4. **User-Friendly Interface**: The intuitive interface simplifies programming and operation, enabling users to quickly adapt to the system. This ease of use reduces training time and boosts productivity.

5. **Robust Reliability**: Built with industrial-grade components, the GE Fanuc is designed to withstand harsh operating conditions, ensuring continuous performance in demanding environments.

6. **Advanced Diagnostics**: The GE Fanuc includes sophisticated diagnostic tools that provide real-time monitoring and troubleshooting capabilities, minimizing downtime and maintenance costs.

**Usage Scenarios**

The GE Fanuc is ideal for a multitude of applications across various industries. Here are some common usage scenarios:

– **Manufacturing Automation**: The GE Fanuc can be utilized to control assembly lines, monitor machinery performance, and ensure quality control throughout the production process.

– **Process Control**: In industries such as oil and gas, pharmaceuticals, and food processing, the GE Fanuc excels in maintaining optimal conditions by regulating temperature, pressure, and flow rates.

– **Building Automation**: From HVAC systems to lighting controls, the GE Fanuc can manage various building functions, leading to increased energy efficiency and improved occupant comfort.

– **Material Handling**: The GE Fanuc is effective in automating warehouse operations, including inventory management, order picking, and shipping processes.

– **Transportation Systems**: Whether managing traffic signals or controlling public transportation systems, the GE Fanuc provides the necessary control and monitoring to improve efficiency and safety.

**Comparison with Other Models**

When comparing the GE Fanuc to other models within the GE portfolio, several distinctions emerge:

– **GE SR750**: While the SR750 is tailored for high-performance applications, the GE Fanuc offers a broader range of automation capabilities, making it more versatile for various industrial environments.

– **GE IS200DSPXH2DBD**: The IS200DSPXH2DBD focuses on specific control and processing tasks. In contrast, the GE Fanuc combines multiple functionalities, accommodating a wider array of applications.

– **GE IC695CPE310-ABAH**: The IC695CPE310-ABAH is known for its compactness and efficiency in smaller setups. In larger, more complex systems, the GE Fanuc shines due to its scalability and modular design.

– **GE DS200DDTBG2A**: This model specializes in drive control applications. The GE Fanuc, on the other hand, offers a more comprehensive solution that integrates drive control with broader automation needs.

– **GE IS220PPDAH1A**: While the IS220PPDAH1A is focused on specific processing tasks, the GE Fanuc is designed for general-purpose automation, making it a suitable choice for businesses seeking flexibility.

**Related Models**

For those interested in exploring additional GE automation products, the following models are worth considering:

1. **GE IC697MDL740**: A reliable discrete output module for various applications.

2. **GE IS200EDFFH1ABA**: A versatile digital output module designed for robust performance.

3. **GE IC200CPU005**: An entry-level PLC suitable for small-scale automation tasks.

4. **GE VMIVME-7671-421000**: A powerful processing module for demanding applications.

5. **GE IC693PWR331**: A power supply module designed to support multiple GE automation products.

6. **GE IS200TRPGH1BDE**: A control module for advanced process control applications.

7. **GE HE693RTM705**: A remote terminal module that extends the reach of GE Fanuc systems.

8. **GE IC200UAL005**: An analog input module for precise data acquisition in industrial settings.

9. **GE DS200TCDAH1BHD**: A terminal board that enhances connectivity in control systems.

10. **GE IC660BBA020**: A programmable logic controller designed for high reliability.

In conclusion, the GE Fanuc stands as a cornerstone of GE's automation product line, offering unmatched performance, flexibility, and reliability. With its advanced features and adaptability to various industries, it is an essential asset for businesses aiming to enhance their operational efficiency and competitiveness. Whether you are looking to streamline your manufacturing processes, improve building management systems, or optimize transportation networks, the GE Fanuc is the solution that meets your automation needs, paving the way for a more productive future.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The GE Fanuc stands out with its robust technical specifications, designed to meet the demanding needs of modern industrial applications. Key features include:

1. **High Processing Power**: The GE Fanuc is equipped with a powerful processor that allows for rapid data processing and real-time control. This capability is crucial for industries that rely on quick decision-making and precise operations.

2. **Versatile Communication Protocols**: Supporting multiple communication protocols, the GE Fanuc ensures seamless integration with various devices and systems. This feature is essential for creating a cohesive automation environment, facilitating easier data exchange and system coordination.

3. **Scalability**: The GE Fanuc is designed to grow with your business. Its modular architecture allows for easy expansion, enabling users to add additional I/O modules, communication options, or processing power as their needs evolve.

4. **User-Friendly Interface**: The intuitive interface simplifies programming and operation, enabling users to quickly adapt to the system. This ease of use reduces training time and boosts productivity.

5. **Robust Reliability**: Built with industrial-grade components, the GE Fanuc is designed to withstand harsh operating conditions, ensuring continuous performance in demanding environments.

6. **Advanced Diagnostics**: The GE Fanuc includes sophisticated diagnostic tools that provide real-time monitoring and troubleshooting capabilities, minimizing downtime and maintenance costs.

**Usage Scenarios**

The GE Fanuc is ideal for a multitude of applications across various industries. Here are some common usage scenarios:

– **Manufacturing Automation**: The GE Fanuc can be utilized to control assembly lines, monitor machinery performance, and ensure quality control throughout the production process.

– **Process Control**: In industries such as oil and gas, pharmaceuticals, and food processing, the GE Fanuc excels in maintaining optimal conditions by regulating temperature, pressure, and flow rates.

– **Building Automation**: From HVAC systems to lighting controls, the GE Fanuc can manage various building functions, leading to increased energy efficiency and improved occupant comfort.

– **Material Handling**: The GE Fanuc is effective in automating warehouse operations, including inventory management, order picking, and shipping processes.

– **Transportation Systems**: Whether managing traffic signals or controlling public transportation systems, the GE Fanuc provides the necessary control and monitoring to improve efficiency and safety.

**Comparison with Other Models**

When comparing the GE Fanuc to other models within the GE portfolio, several distinctions emerge:

– **GE SR750**: While the SR750 is tailored for high-performance applications, the GE Fanuc offers a broader range of automation capabilities, making it more versatile for various industrial environments.

– **GE IS200DSPXH2DBD**: The IS200DSPXH2DBD focuses on specific control and processing tasks. In contrast, the GE Fanuc combines multiple functionalities, accommodating a wider array of applications.

– **GE IC695CPE310-ABAH**: The IC695CPE310-ABAH is known for its compactness and efficiency in smaller setups. In larger, more complex systems, the GE Fanuc shines due to its scalability and modular design.

– **GE DS200DDTBG2A**: This model specializes in drive control applications. The GE Fanuc, on the other hand, offers a more comprehensive solution that integrates drive control with broader automation needs.

– **GE IS220PPDAH1A**: While the IS220PPDAH1A is focused on specific processing tasks, the GE Fanuc is designed for general-purpose automation, making it a suitable choice for businesses seeking flexibility.

**Related Models**

For those interested in exploring additional GE automation products, the following models are worth considering:

1. **GE IC697MDL740**: A reliable discrete output module for various applications.

2. **GE IS200EDFFH1ABA**: A versatile digital output module designed for robust performance.

3. **GE IC200CPU005**: An entry-level PLC suitable for small-scale automation tasks.

4. **GE VMIVME-7671-421000**: A powerful processing module for demanding applications.

5. **GE IC693PWR331**: A power supply module designed to support multiple GE automation products.

6. **GE IS200TRPGH1BDE**: A control module for advanced process control applications.

7. **GE HE693RTM705**: A remote terminal module that extends the reach of GE Fanuc systems.

8. **GE IC200UAL005**: An analog input module for precise data acquisition in industrial settings.

9. **GE DS200TCDAH1BHD**: A terminal board that enhances connectivity in control systems.

10. **GE IC660BBA020**: A programmable logic controller designed for high reliability.

In conclusion, the GE Fanuc stands as a cornerstone of GE's automation product line, offering unmatched performance, flexibility, and reliability. With its advanced features and adaptability to various industries, it is an essential asset for businesses aiming to enhance their operational efficiency and competitiveness. Whether you are looking to streamline your manufacturing processes, improve building management systems, or optimize transportation networks, the GE Fanuc is the solution that meets your automation needs, paving the way for a more productive future.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.