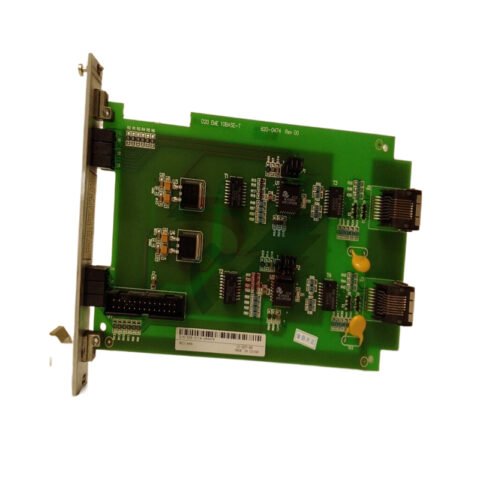

GE Fanuc TGT-3X6L-1-0-BD Servo Power Module

Introducing the GE Fanuc Model: A Pinnacle of Automation Excellence

In the ever-evolving landscape of industrial automation, the GE Fanuc series stands out as a benchmark for reliability and efficiency. Designed to meet the rigorous demands of today’s manufacturing environments, the GE Fanuc model combines advanced technology with user-oriented features, making it a preferred choice for professionals across various sectors.

Key Technical Features

The GE Fanuc model integrates several cutting-edge technical features that set it apart from the competition. At its core, the model is equipped with a robust processing unit capable of handling complex tasks with unparalleled speed and accuracy. It boasts a high-performance CPU that ensures seamless data processing, enabling real-time monitoring and control of industrial processes.

Connectivity is another strong point of the GE Fanuc model. With multiple communication protocols, including Ethernet and serial connections, it supports a wide array of devices, facilitating smooth integration within existing systems. This interoperability is crucial for streamlining operations and enhancing productivity.

The GE Fanuc model also features extensive I/O capabilities, allowing for the connection of various sensors, actuators, and other peripherals. The modular design means that users can easily expand their systems to accommodate future needs without the hassle of major overhauls. Additionally, built-in diagnostic tools assist in troubleshooting, reducing downtime and maintenance costs.

Safety is paramount in industrial environments, and the GE Fanuc model addresses this with advanced safety features. It complies with international safety standards, ensuring that operators can work in a secure environment while minimizing risks associated with automation processes.

Usage Scenarios

The versatility of the GE Fanuc model makes it suitable for various applications across multiple industries. In manufacturing, it can be used to automate assembly lines, significantly increasing throughput and ensuring consistent product quality. The ability to monitor machine performance in real-time allows operators to make data-driven decisions, optimizing production efficiency.

In the energy sector, the GE Fanuc model is instrumental in controlling and monitoring power generation systems. Its capabilities extend to the oil and gas industry, where it can be employed for real-time data acquisition and control of drilling operations, enhancing safety and performance.

Moreover, the GE Fanuc model is ideal for the transportation sector, where it can facilitate traffic management systems, ensuring smooth and efficient transit operations. Whether used in smart factories or for infrastructure management, the GE Fanuc model proves to be a reliable and efficient automation solution.

Comparison with Other Models

When compared to other models in the GE portfolio, such as the GE SR750 or the GE IC697MDL740, the GE Fanuc model distinguishes itself through its superior processing capabilities and enhanced connectivity options. While the GE SR750 offers robust performance for specific applications, the GE Fanuc model provides a more flexible and versatile platform suitable for a wider range of industrial automation tasks.

In contrast to the GE IS200DSPXH2DBD, which is primarily designed for specific control applications, the GE Fanuc model serves as a comprehensive solution that can adapt to various industrial requirements. Its modular architecture allows users to customize their systems according to their unique demands, a feature that is not as prevalent in some of the more specialized models.

Additionally, the GE Fanuc model's extensive I/O capabilities and built-in diagnostics set it apart from models like the GE IC200CPU005 and the GE IC3600A0AHIC. These features not only enhance functionality but also simplify maintenance and troubleshooting processes, ultimately leading to reduced operational costs.

Related Models

For those exploring GE automation products, the following related models may also be of interest:

1. GE SR750 – A reliable solution for specific industrial tasks.

2. GE IC697MDL740 – A versatile model with multiple I/O options.

3. GE IS200DSFCG1AEB – Focused on specialized control applications.

4. GE IC660BBA020 – A highly efficient controller for various industries.

5. GE DS200DDTBG2A – A robust option for demanding environments.

6. GE IS200DSPXH2DBD – Ideal for process control needs.

7. GE ALG – A foundational model for automation solutions.

8. GE IC693APU301 – Known for its reliability in automation.

9. GE IS200EDFFH1ABA – Tailored for precise control applications.

10. GE IC695CPE310-ABAH – Another excellent choice for industrial automation.

Conclusion

The GE Fanuc model exemplifies the pinnacle of automation technology, providing users with a reliable, flexible, and efficient solution for their industrial automation needs. With its advanced technical features, extensive usage scenarios, and a competitive edge over other models, it is clear why the GE Fanuc series remains a top choice among professionals in the automation field.

For those looking to enhance their operational efficiency, investing in GE automation products like the GE Fanuc model is a step towards achieving greater productivity and innovation in their respective industries. Experience the future of automation with GE Fanuc and redefine what is possible in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the ever-evolving landscape of industrial automation, the GE Fanuc series stands out as a benchmark for reliability and efficiency. Designed to meet the rigorous demands of today’s manufacturing environments, the GE Fanuc model combines advanced technology with user-oriented features, making it a preferred choice for professionals across various sectors.

Key Technical Features

The GE Fanuc model integrates several cutting-edge technical features that set it apart from the competition. At its core, the model is equipped with a robust processing unit capable of handling complex tasks with unparalleled speed and accuracy. It boasts a high-performance CPU that ensures seamless data processing, enabling real-time monitoring and control of industrial processes.

Connectivity is another strong point of the GE Fanuc model. With multiple communication protocols, including Ethernet and serial connections, it supports a wide array of devices, facilitating smooth integration within existing systems. This interoperability is crucial for streamlining operations and enhancing productivity.

The GE Fanuc model also features extensive I/O capabilities, allowing for the connection of various sensors, actuators, and other peripherals. The modular design means that users can easily expand their systems to accommodate future needs without the hassle of major overhauls. Additionally, built-in diagnostic tools assist in troubleshooting, reducing downtime and maintenance costs.

Safety is paramount in industrial environments, and the GE Fanuc model addresses this with advanced safety features. It complies with international safety standards, ensuring that operators can work in a secure environment while minimizing risks associated with automation processes.

Usage Scenarios

The versatility of the GE Fanuc model makes it suitable for various applications across multiple industries. In manufacturing, it can be used to automate assembly lines, significantly increasing throughput and ensuring consistent product quality. The ability to monitor machine performance in real-time allows operators to make data-driven decisions, optimizing production efficiency.

In the energy sector, the GE Fanuc model is instrumental in controlling and monitoring power generation systems. Its capabilities extend to the oil and gas industry, where it can be employed for real-time data acquisition and control of drilling operations, enhancing safety and performance.

Moreover, the GE Fanuc model is ideal for the transportation sector, where it can facilitate traffic management systems, ensuring smooth and efficient transit operations. Whether used in smart factories or for infrastructure management, the GE Fanuc model proves to be a reliable and efficient automation solution.

Comparison with Other Models

When compared to other models in the GE portfolio, such as the GE SR750 or the GE IC697MDL740, the GE Fanuc model distinguishes itself through its superior processing capabilities and enhanced connectivity options. While the GE SR750 offers robust performance for specific applications, the GE Fanuc model provides a more flexible and versatile platform suitable for a wider range of industrial automation tasks.

In contrast to the GE IS200DSPXH2DBD, which is primarily designed for specific control applications, the GE Fanuc model serves as a comprehensive solution that can adapt to various industrial requirements. Its modular architecture allows users to customize their systems according to their unique demands, a feature that is not as prevalent in some of the more specialized models.

Additionally, the GE Fanuc model's extensive I/O capabilities and built-in diagnostics set it apart from models like the GE IC200CPU005 and the GE IC3600A0AHIC. These features not only enhance functionality but also simplify maintenance and troubleshooting processes, ultimately leading to reduced operational costs.

Related Models

For those exploring GE automation products, the following related models may also be of interest:

1. GE SR750 – A reliable solution for specific industrial tasks.

2. GE IC697MDL740 – A versatile model with multiple I/O options.

3. GE IS200DSFCG1AEB – Focused on specialized control applications.

4. GE IC660BBA020 – A highly efficient controller for various industries.

5. GE DS200DDTBG2A – A robust option for demanding environments.

6. GE IS200DSPXH2DBD – Ideal for process control needs.

7. GE ALG – A foundational model for automation solutions.

8. GE IC693APU301 – Known for its reliability in automation.

9. GE IS200EDFFH1ABA – Tailored for precise control applications.

10. GE IC695CPE310-ABAH – Another excellent choice for industrial automation.

Conclusion

The GE Fanuc model exemplifies the pinnacle of automation technology, providing users with a reliable, flexible, and efficient solution for their industrial automation needs. With its advanced technical features, extensive usage scenarios, and a competitive edge over other models, it is clear why the GE Fanuc series remains a top choice among professionals in the automation field.

For those looking to enhance their operational efficiency, investing in GE automation products like the GE Fanuc model is a step towards achieving greater productivity and innovation in their respective industries. Experience the future of automation with GE Fanuc and redefine what is possible in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.