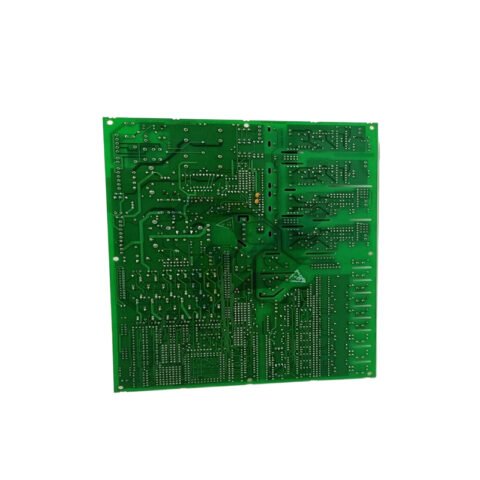

GE FANUC UR6UH Digital I/O Module for Universal Robots

Introducing the GE FANUC, a pinnacle of innovation in the realm of automation and control systems. Renowned for its reliability and performance, the GE FANUC series stands as a testament to GE's commitment to delivering cutting-edge technology tailored for various industrial applications. This product description delves into its key technical features, usage scenarios, comparisons with other models, and references related models to provide a comprehensive understanding of why the GE FANUC is a valuable asset in any automation setup.

**Key Technical Features**

The GE FANUC is designed with advanced capabilities that enhance operational efficiency and reliability. Some of its standout features include:

1. **High Processing Power**: The GE FANUC boasts a robust processing architecture that enables rapid data processing and real-time control. This is critical in environments where timely decisions can significantly impact productivity and safety.

2. **Versatile Communication Protocols**: This model supports multiple communication protocols, allowing seamless integration with various GE automation products and third-party devices. The flexibility in communication ensures that users can customize their systems according to specific operational needs.

3. **Scalability**: The GE FANUC is built to grow with your business. Whether you are a small enterprise or a large industrial operation, this model can be scaled to accommodate increased demands without compromising performance.

4. **User-Friendly Interface**: With its intuitive interface, the GE FANUC simplifies the user experience, making it easier for operators to monitor and control processes. This feature minimizes training time and maximizes efficiency.

5. **Robust Safety Features**: Safety is paramount in industrial environments. The GE FANUC is engineered with built-in safety protocols that help mitigate risks, ensuring that operations can proceed without compromising worker safety or equipment integrity.

6. **Durability and Reliability**: Designed for harsh industrial conditions, the GE FANUC is constructed with high-quality materials that can withstand extreme temperatures, vibrations, and other challenging environmental factors.

**Usage Scenarios**

The versatility of the GE FANUC makes it suitable for a wide range of applications. Here are some typical scenarios where this model excels:

1. **Manufacturing Automation**: In manufacturing settings, the GE FANUC is utilized for controlling assembly lines, coordinating robotic arms, and managing production schedules. Its high processing power ensures that operations run smoothly and efficiently.

2. **Energy Management**: The GE FANUC can be employed in energy management systems to monitor and control power distribution, optimizing energy consumption and improving sustainability efforts.

3. **Transportation Systems**: From traffic control systems to automated public transport solutions, the GE FANUC plays a crucial role in enhancing the efficiency and safety of transportation networks.

4. **Water and Wastewater Treatment**: In environmental management, the GE FANUC is instrumental in controlling the processes involved in water purification and wastewater treatment, ensuring compliance with environmental regulations.

5. **Building Automation**: The model is also applicable in building management systems, where it oversees HVAC, lighting, and security systems, enhancing comfort and energy efficiency in commercial buildings.

**Comparison with Other Models**

When comparing the GE FANUC with other models within the GE automation product lineup, it stands out in several ways. For instance, while the GE SR750 is known for its strong data acquisition capabilities, the GE FANUC offers superior processing speed and scalability, making it a better choice for complex automation tasks.

Similarly, the GE IS200DSPXH2DBD model is excellent for specific control applications, but the GE FANUC provides broader versatility for users who require a multi-faceted solution. Compared to the GE IC695CPE310-ABAH, which focuses on compact applications, the GE FANUC is more adept at handling larger and more intricate systems.

In contrast to models like the GE IC200CPU005, which is designed for entry-level applications, the GE FANUC caters to advanced users seeking high performance and extensive features. This positioning makes the GE FANUC an ideal choice for enterprises looking to invest in an adaptable and future-proof automation solution.

**Related Models**

The GE FANUC is part of a comprehensive ecosystem of GE automation products, allowing users to leverage complementary technologies for enhanced performance. Here are ten related models that can further enrich your automation strategy:

1. **GE SR750**: Known for its strong data acquisition capabilities.

2. **GE IS200DSFCG1AEB**: A model that excels in specific control applications.

3. **GE IC660BBA020**: Offers unique communication capabilities for various applications.

4. **GE DS200DDTBG2A**: A reliable choice for digital input/output control.

5. **GE IS200DSPXH2DBD**: Focuses on specific control tasks with precision.

6. **GE IS220PPDAH1A**: Ideal for process control applications.

7. **GE IC693APU301**: A versatile processing unit that can complement the GE FANUC.

8. **GE IC695CPE310-ABAH**: Compact but effective for smaller applications.

9. **GE IC200CPU005**: Entry-level model for basic automation needs.

10. **GE IS200EDFFH1ABA**: Designed for advanced applications requiring high performance.

In conclusion, the GE FANUC represents a powerful and flexible solution for modern automation needs. With its high processing power, versatile communication options, and scalability, it is uniquely positioned to meet the demands of various industries. Whether you are looking to enhance manufacturing processes, improve energy management, or streamline building automation, the GE FANUC stands out as a leading choice among GE automation products. Embrace the future of automation with the GE FANUC and unlock new levels of efficiency and control.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The GE FANUC is designed with advanced capabilities that enhance operational efficiency and reliability. Some of its standout features include:

1. **High Processing Power**: The GE FANUC boasts a robust processing architecture that enables rapid data processing and real-time control. This is critical in environments where timely decisions can significantly impact productivity and safety.

2. **Versatile Communication Protocols**: This model supports multiple communication protocols, allowing seamless integration with various GE automation products and third-party devices. The flexibility in communication ensures that users can customize their systems according to specific operational needs.

3. **Scalability**: The GE FANUC is built to grow with your business. Whether you are a small enterprise or a large industrial operation, this model can be scaled to accommodate increased demands without compromising performance.

4. **User-Friendly Interface**: With its intuitive interface, the GE FANUC simplifies the user experience, making it easier for operators to monitor and control processes. This feature minimizes training time and maximizes efficiency.

5. **Robust Safety Features**: Safety is paramount in industrial environments. The GE FANUC is engineered with built-in safety protocols that help mitigate risks, ensuring that operations can proceed without compromising worker safety or equipment integrity.

6. **Durability and Reliability**: Designed for harsh industrial conditions, the GE FANUC is constructed with high-quality materials that can withstand extreme temperatures, vibrations, and other challenging environmental factors.

**Usage Scenarios**

The versatility of the GE FANUC makes it suitable for a wide range of applications. Here are some typical scenarios where this model excels:

1. **Manufacturing Automation**: In manufacturing settings, the GE FANUC is utilized for controlling assembly lines, coordinating robotic arms, and managing production schedules. Its high processing power ensures that operations run smoothly and efficiently.

2. **Energy Management**: The GE FANUC can be employed in energy management systems to monitor and control power distribution, optimizing energy consumption and improving sustainability efforts.

3. **Transportation Systems**: From traffic control systems to automated public transport solutions, the GE FANUC plays a crucial role in enhancing the efficiency and safety of transportation networks.

4. **Water and Wastewater Treatment**: In environmental management, the GE FANUC is instrumental in controlling the processes involved in water purification and wastewater treatment, ensuring compliance with environmental regulations.

5. **Building Automation**: The model is also applicable in building management systems, where it oversees HVAC, lighting, and security systems, enhancing comfort and energy efficiency in commercial buildings.

**Comparison with Other Models**

When comparing the GE FANUC with other models within the GE automation product lineup, it stands out in several ways. For instance, while the GE SR750 is known for its strong data acquisition capabilities, the GE FANUC offers superior processing speed and scalability, making it a better choice for complex automation tasks.

Similarly, the GE IS200DSPXH2DBD model is excellent for specific control applications, but the GE FANUC provides broader versatility for users who require a multi-faceted solution. Compared to the GE IC695CPE310-ABAH, which focuses on compact applications, the GE FANUC is more adept at handling larger and more intricate systems.

In contrast to models like the GE IC200CPU005, which is designed for entry-level applications, the GE FANUC caters to advanced users seeking high performance and extensive features. This positioning makes the GE FANUC an ideal choice for enterprises looking to invest in an adaptable and future-proof automation solution.

**Related Models**

The GE FANUC is part of a comprehensive ecosystem of GE automation products, allowing users to leverage complementary technologies for enhanced performance. Here are ten related models that can further enrich your automation strategy:

1. **GE SR750**: Known for its strong data acquisition capabilities.

2. **GE IS200DSFCG1AEB**: A model that excels in specific control applications.

3. **GE IC660BBA020**: Offers unique communication capabilities for various applications.

4. **GE DS200DDTBG2A**: A reliable choice for digital input/output control.

5. **GE IS200DSPXH2DBD**: Focuses on specific control tasks with precision.

6. **GE IS220PPDAH1A**: Ideal for process control applications.

7. **GE IC693APU301**: A versatile processing unit that can complement the GE FANUC.

8. **GE IC695CPE310-ABAH**: Compact but effective for smaller applications.

9. **GE IC200CPU005**: Entry-level model for basic automation needs.

10. **GE IS200EDFFH1ABA**: Designed for advanced applications requiring high performance.

In conclusion, the GE FANUC represents a powerful and flexible solution for modern automation needs. With its high processing power, versatile communication options, and scalability, it is uniquely positioned to meet the demands of various industries. Whether you are looking to enhance manufacturing processes, improve energy management, or streamline building automation, the GE FANUC stands out as a leading choice among GE automation products. Embrace the future of automation with the GE FANUC and unlock new levels of efficiency and control.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.