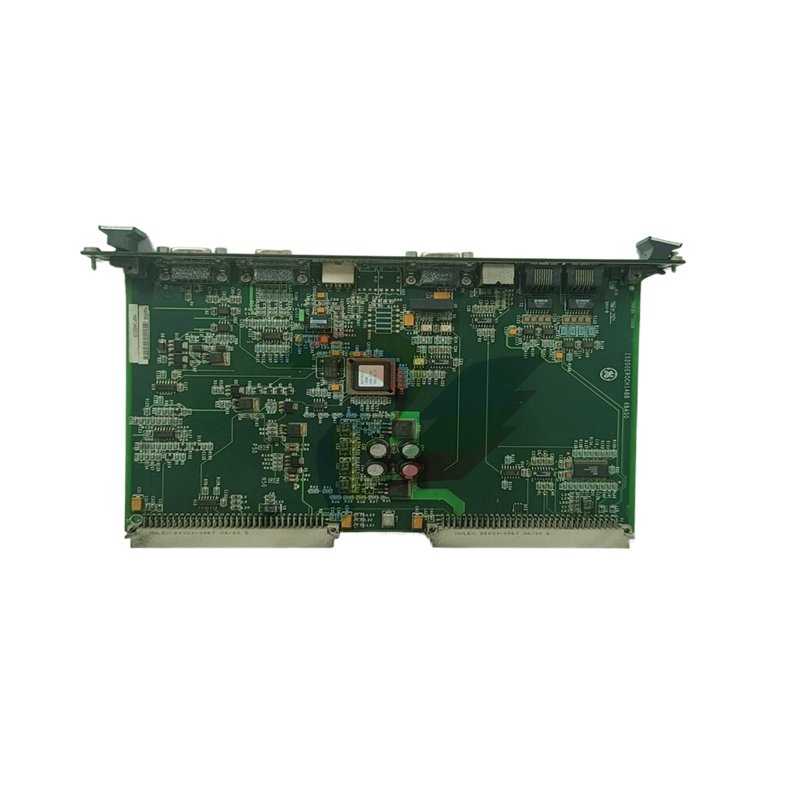

GE Fanuc VMIVME-1182 Digital Input Module Intelligent & Isolated for Industrial Control

Introducing the GE Fanuc: the pinnacle of industrial automation technology. As part of GE's renowned family of automation products, the GE Fanuc model is engineered for performance, reliability, and versatility, making it an essential component for modern manufacturing and industrial processes. This product description delves into its key technical features, potential usage scenarios, comparisons with other models, and references related products within the GE ecosystem.

### Key Technical Features

The GE Fanuc is designed with cutting-edge technology that enhances operational efficiency and consistency. Some of its standout features include:

1. **Robust Processing Power**: Equipped with a high-speed processor, the GE Fanuc delivers rapid data processing and real-time performance, ensuring that your operations are not only efficient but also responsive to changing conditions.

2. **Flexible I/O Configurations**: The model supports a wide array of input and output configurations, allowing it to adapt to various applications, from simple machine controls to complex automated systems. This flexibility makes it suitable for diverse industrial environments.

3. **Integrated Networking Capabilities**: The GE Fanuc features advanced networking options that ensure seamless communication between devices, enabling integration into your existing systems with ease. This connectivity is crucial for modern smart factories that rely on interconnected machinery.

4. **User-Friendly Interface**: Designed with an intuitive user interface, the GE Fanuc simplifies setup and operation. Operators can easily monitor and manage processes, reducing the learning curve and minimizing downtime.

5. **High Reliability and Durability**: Built to withstand harsh industrial environments, the GE Fanuc is resistant to temperature variations, shock, and vibration. This ruggedness ensures longevity and consistent performance, even in the most demanding conditions.

6. **Comprehensive Diagnostic Tools**: The model comes equipped with advanced diagnostic capabilities that facilitate troubleshooting and maintenance, allowing for quick resolution of issues and reducing operational disruptions.

### Usage Scenarios

The GE Fanuc model excels in a variety of applications across multiple industries. Some prominent usage scenarios include:

– **Manufacturing Automation**: In manufacturing settings, the GE Fanuc can control assembly lines, monitor machinery performance, and optimize production schedules. Its robust processing power and I/O capabilities allow for precise control and monitoring of various manufacturing processes.

– **Process Control**: The model is ideal for process control applications in industries such as oil and gas, chemical processing, and food and beverage. Its ability to integrate with various sensors and actuators enables precise control of critical processes.

– **Building Automation**: The GE Fanuc can be utilized in building management systems for HVAC control, lighting management, and security systems. Its networking capabilities allow it to communicate with other building systems to optimize energy efficiency and occupant comfort.

– **Robotics**: In automation involving robotics, the GE Fanuc can serve as the central control unit, coordinating multiple robotic arms and ensuring synchronized operation for tasks such as assembly, welding, or packaging.

– **Energy Management**: The model can also play a crucial role in energy management systems, helping facilities monitor energy consumption, optimize usage, and reduce costs through automation.

### Comparison with Other Models

When comparing the GE Fanuc with other models within the GE automation products lineup, several key differences emerge. For example, while the GE SR750 offers enhanced performance for specific applications, the GE Fanuc provides a more comprehensive solution suitable for a wider range of industries.

In contrast to the GE IS200DSPXH2DBD, which is specialized for specific control applications, the GE Fanuc boasts greater flexibility and adaptability, making it ideal for diverse industrial environments. Additionally, the GE IC695CPE310-ABAH, while powerful, does not offer the same level of user-friendly interface and diagnostic tools that the GE Fanuc presents.

The GE Fanuc also stands out when compared to legacy models like the GE IC3600A0AHIC, which may lack the advanced networking capabilities and robust processing power of the newer GE Fanuc model. Thus, the GE Fanuc is positioned as a modern solution that meets the demands of today's fast-paced industrial landscape.

### Related Models

To provide a broader context and help you explore the GE ecosystem further, here are ten related models that complement the capabilities of the GE Fanuc:

1. **GE SR750**: A high-performance controller known for its advanced processing capabilities.

2. **GE IC697MDL740**: A versatile I/O module designed for various automation tasks.

3. **GE IS200DSFCG1AEB**: A specialized control module for dynamic systems.

4. **GE IC660BBA020**: An advanced bus interface that facilitates communication between devices.

5. **GE DS200DDTBG2A**: A digital output terminal board for extensive automation setups.

6. **GE IS200DSPXH2DBD**: A high-speed processor for specific automation applications.

7. **GE IC693APU301**: An advanced power supply unit for enhanced system performance.

8. **GE IS200JPDMG1ADC**: A process control module tailored for precise operations.

9. **GE IC695LRE001B**: A versatile relay module for various applications.

10. **GE IS420YDOAS1B**: An output module designed for high-performance automation tasks.

In conclusion, the GE Fanuc is a powerhouse of industrial automation, equipped with features that cater to a wide range of applications. It stands out for its processing capabilities, flexibility, and reliability, making it an ideal choice for businesses looking to enhance their automation processes. With its user-friendly interface and robust performance, the GE Fanuc continues to lead the way in GE automation products, positioning itself as a vital asset for industries ready to embrace the future of automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

### Key Technical Features

The GE Fanuc is designed with cutting-edge technology that enhances operational efficiency and consistency. Some of its standout features include:

1. **Robust Processing Power**: Equipped with a high-speed processor, the GE Fanuc delivers rapid data processing and real-time performance, ensuring that your operations are not only efficient but also responsive to changing conditions.

2. **Flexible I/O Configurations**: The model supports a wide array of input and output configurations, allowing it to adapt to various applications, from simple machine controls to complex automated systems. This flexibility makes it suitable for diverse industrial environments.

3. **Integrated Networking Capabilities**: The GE Fanuc features advanced networking options that ensure seamless communication between devices, enabling integration into your existing systems with ease. This connectivity is crucial for modern smart factories that rely on interconnected machinery.

4. **User-Friendly Interface**: Designed with an intuitive user interface, the GE Fanuc simplifies setup and operation. Operators can easily monitor and manage processes, reducing the learning curve and minimizing downtime.

5. **High Reliability and Durability**: Built to withstand harsh industrial environments, the GE Fanuc is resistant to temperature variations, shock, and vibration. This ruggedness ensures longevity and consistent performance, even in the most demanding conditions.

6. **Comprehensive Diagnostic Tools**: The model comes equipped with advanced diagnostic capabilities that facilitate troubleshooting and maintenance, allowing for quick resolution of issues and reducing operational disruptions.

### Usage Scenarios

The GE Fanuc model excels in a variety of applications across multiple industries. Some prominent usage scenarios include:

– **Manufacturing Automation**: In manufacturing settings, the GE Fanuc can control assembly lines, monitor machinery performance, and optimize production schedules. Its robust processing power and I/O capabilities allow for precise control and monitoring of various manufacturing processes.

– **Process Control**: The model is ideal for process control applications in industries such as oil and gas, chemical processing, and food and beverage. Its ability to integrate with various sensors and actuators enables precise control of critical processes.

– **Building Automation**: The GE Fanuc can be utilized in building management systems for HVAC control, lighting management, and security systems. Its networking capabilities allow it to communicate with other building systems to optimize energy efficiency and occupant comfort.

– **Robotics**: In automation involving robotics, the GE Fanuc can serve as the central control unit, coordinating multiple robotic arms and ensuring synchronized operation for tasks such as assembly, welding, or packaging.

– **Energy Management**: The model can also play a crucial role in energy management systems, helping facilities monitor energy consumption, optimize usage, and reduce costs through automation.

### Comparison with Other Models

When comparing the GE Fanuc with other models within the GE automation products lineup, several key differences emerge. For example, while the GE SR750 offers enhanced performance for specific applications, the GE Fanuc provides a more comprehensive solution suitable for a wider range of industries.

In contrast to the GE IS200DSPXH2DBD, which is specialized for specific control applications, the GE Fanuc boasts greater flexibility and adaptability, making it ideal for diverse industrial environments. Additionally, the GE IC695CPE310-ABAH, while powerful, does not offer the same level of user-friendly interface and diagnostic tools that the GE Fanuc presents.

The GE Fanuc also stands out when compared to legacy models like the GE IC3600A0AHIC, which may lack the advanced networking capabilities and robust processing power of the newer GE Fanuc model. Thus, the GE Fanuc is positioned as a modern solution that meets the demands of today's fast-paced industrial landscape.

### Related Models

To provide a broader context and help you explore the GE ecosystem further, here are ten related models that complement the capabilities of the GE Fanuc:

1. **GE SR750**: A high-performance controller known for its advanced processing capabilities.

2. **GE IC697MDL740**: A versatile I/O module designed for various automation tasks.

3. **GE IS200DSFCG1AEB**: A specialized control module for dynamic systems.

4. **GE IC660BBA020**: An advanced bus interface that facilitates communication between devices.

5. **GE DS200DDTBG2A**: A digital output terminal board for extensive automation setups.

6. **GE IS200DSPXH2DBD**: A high-speed processor for specific automation applications.

7. **GE IC693APU301**: An advanced power supply unit for enhanced system performance.

8. **GE IS200JPDMG1ADC**: A process control module tailored for precise operations.

9. **GE IC695LRE001B**: A versatile relay module for various applications.

10. **GE IS420YDOAS1B**: An output module designed for high-performance automation tasks.

In conclusion, the GE Fanuc is a powerhouse of industrial automation, equipped with features that cater to a wide range of applications. It stands out for its processing capabilities, flexibility, and reliability, making it an ideal choice for businesses looking to enhance their automation processes. With its user-friendly interface and robust performance, the GE Fanuc continues to lead the way in GE automation products, positioning itself as a vital asset for industries ready to embrace the future of automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.