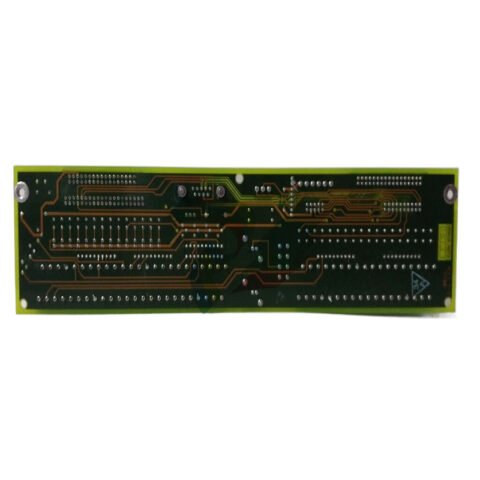

GE Fanuc VMIVME 6015 I/O Board

Introducing the GE Fanuc, a powerhouse in the realm of industrial automation and control systems. Renowned for its reliability and advanced technology, the GE Fanuc model is specifically engineered to meet the demands of modern industrial environments, making it an essential component for businesses looking to optimize their operations.

**Key Technical Features**

The GE Fanuc model boasts an array of cutting-edge features designed to enhance efficiency and streamline processes. With a robust architecture, it offers exceptional processing power, ensuring rapid data handling and decision-making capabilities. The model is equipped with a high-performance CPU, supporting extensive input/output (I/O) configurations, which allows for seamless integration with various industrial sensors and actuators.

One of the standout features of the GE Fanuc is its scalability. Users can easily expand their systems to accommodate growing operational needs, making it an ideal choice for both small and large enterprises. The model supports multiple communication protocols, including Ethernet/IP, Modbus, and Profibus, facilitating interoperability with other GE automation products and third-party devices.

Additionally, the GE Fanuc incorporates advanced diagnostic and troubleshooting tools that enable users to monitor system performance in real-time. This proactive approach minimizes downtime and enhances overall productivity. Furthermore, its user-friendly interface simplifies programming and configuration, allowing operators to focus on their core tasks rather than getting bogged down by technical complexities.

**Usage Scenarios**

The GE Fanuc model is versatile and can be effectively deployed across various industries. In manufacturing, it excels in process control applications, managing everything from assembly lines to packaging systems. Its fast response times and reliable performance ensure that productivity remains high even under demanding conditions.

In the energy sector, the GE Fanuc model plays a crucial role in monitoring and controlling power generation and distribution systems. Its ability to interface with various sensors and devices allows for precise control over complex operations, ensuring the efficient use of resources.

Furthermore, the model is well-suited for transportation and logistics applications. It can be integrated into systems that track inventory levels, manage supply chains, and optimize routing for vehicles, leading to improved operational efficiency and reduced costs.

**Comparison with Other Models**

When comparing the GE Fanuc to other models within the GE family, such as the GE SR750 and GE IC697MDL740, it becomes evident that GE Fanuc stands out due to its advanced processing capabilities and extensive scalability. While models like the GE SR750 are excellent for specific applications, the GE Fanuc’s versatility and robust architecture make it a preferred choice for a broad range of industrial operations.

In contrast to the GE IS200DSPXH2DBD, which is tailored for specialized control applications, the GE Fanuc offers greater integration capabilities, allowing it to function seamlessly within a diverse ecosystem of GE automation products. This makes it an ideal solution for businesses seeking to implement a comprehensive automation strategy.

Another notable comparison can be made with the GE IC693APU301, which is aimed at enhancing PLC performance. While both models deliver strong performance, the GE Fanuc offers superior connectivity options and a more intuitive user interface, making it easier for operators to manage complex systems.

**Related Models**

For businesses exploring their options within the GE automation product line, several related models complement the GE Fanuc perfectly. These include:

1. GE SR750 – Known for its reliability in process control applications.

2. GE IS200DSFCG1AEB – Ideal for specialized control needs.

3. GE IC660BBA020 – Designed for advanced data acquisition.

4. GE DS200DDTBG2A – A robust option for digital input/output applications.

5. GE IS200DSPXH2DBD – Tailored for specific control systems.

6. GE IC693APU301 – Enhances PLC performance in industrial settings.

7. GE IS200EDFFH1ABA – Offers advanced digital control features.

8. GE IC695CPE310-ABAH – Provides high processing power for demanding applications.

9. GE DS200SVAAG1A – A solid choice for system monitoring and control.

10. GE IC200CPU005 – A reliable option for basic control tasks.

**Conclusion**

In summary, the GE Fanuc model represents the epitome of industrial automation and control technology. With its impressive technical features, versatile usage scenarios, and clear advantages over other models, it stands out as a top choice for companies looking to enhance their operational efficiency. The seamless integration capabilities with other GE automation products further solidify its status as a cornerstone in modern industrial applications. By investing in the GE Fanuc, businesses are positioning themselves for success in an increasingly competitive landscape, equipped with the tools necessary to thrive in the world of automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The GE Fanuc model boasts an array of cutting-edge features designed to enhance efficiency and streamline processes. With a robust architecture, it offers exceptional processing power, ensuring rapid data handling and decision-making capabilities. The model is equipped with a high-performance CPU, supporting extensive input/output (I/O) configurations, which allows for seamless integration with various industrial sensors and actuators.

One of the standout features of the GE Fanuc is its scalability. Users can easily expand their systems to accommodate growing operational needs, making it an ideal choice for both small and large enterprises. The model supports multiple communication protocols, including Ethernet/IP, Modbus, and Profibus, facilitating interoperability with other GE automation products and third-party devices.

Additionally, the GE Fanuc incorporates advanced diagnostic and troubleshooting tools that enable users to monitor system performance in real-time. This proactive approach minimizes downtime and enhances overall productivity. Furthermore, its user-friendly interface simplifies programming and configuration, allowing operators to focus on their core tasks rather than getting bogged down by technical complexities.

**Usage Scenarios**

The GE Fanuc model is versatile and can be effectively deployed across various industries. In manufacturing, it excels in process control applications, managing everything from assembly lines to packaging systems. Its fast response times and reliable performance ensure that productivity remains high even under demanding conditions.

In the energy sector, the GE Fanuc model plays a crucial role in monitoring and controlling power generation and distribution systems. Its ability to interface with various sensors and devices allows for precise control over complex operations, ensuring the efficient use of resources.

Furthermore, the model is well-suited for transportation and logistics applications. It can be integrated into systems that track inventory levels, manage supply chains, and optimize routing for vehicles, leading to improved operational efficiency and reduced costs.

**Comparison with Other Models**

When comparing the GE Fanuc to other models within the GE family, such as the GE SR750 and GE IC697MDL740, it becomes evident that GE Fanuc stands out due to its advanced processing capabilities and extensive scalability. While models like the GE SR750 are excellent for specific applications, the GE Fanuc’s versatility and robust architecture make it a preferred choice for a broad range of industrial operations.

In contrast to the GE IS200DSPXH2DBD, which is tailored for specialized control applications, the GE Fanuc offers greater integration capabilities, allowing it to function seamlessly within a diverse ecosystem of GE automation products. This makes it an ideal solution for businesses seeking to implement a comprehensive automation strategy.

Another notable comparison can be made with the GE IC693APU301, which is aimed at enhancing PLC performance. While both models deliver strong performance, the GE Fanuc offers superior connectivity options and a more intuitive user interface, making it easier for operators to manage complex systems.

**Related Models**

For businesses exploring their options within the GE automation product line, several related models complement the GE Fanuc perfectly. These include:

1. GE SR750 – Known for its reliability in process control applications.

2. GE IS200DSFCG1AEB – Ideal for specialized control needs.

3. GE IC660BBA020 – Designed for advanced data acquisition.

4. GE DS200DDTBG2A – A robust option for digital input/output applications.

5. GE IS200DSPXH2DBD – Tailored for specific control systems.

6. GE IC693APU301 – Enhances PLC performance in industrial settings.

7. GE IS200EDFFH1ABA – Offers advanced digital control features.

8. GE IC695CPE310-ABAH – Provides high processing power for demanding applications.

9. GE DS200SVAAG1A – A solid choice for system monitoring and control.

10. GE IC200CPU005 – A reliable option for basic control tasks.

**Conclusion**

In summary, the GE Fanuc model represents the epitome of industrial automation and control technology. With its impressive technical features, versatile usage scenarios, and clear advantages over other models, it stands out as a top choice for companies looking to enhance their operational efficiency. The seamless integration capabilities with other GE automation products further solidify its status as a cornerstone in modern industrial applications. By investing in the GE Fanuc, businesses are positioning themselves for success in an increasingly competitive landscape, equipped with the tools necessary to thrive in the world of automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.