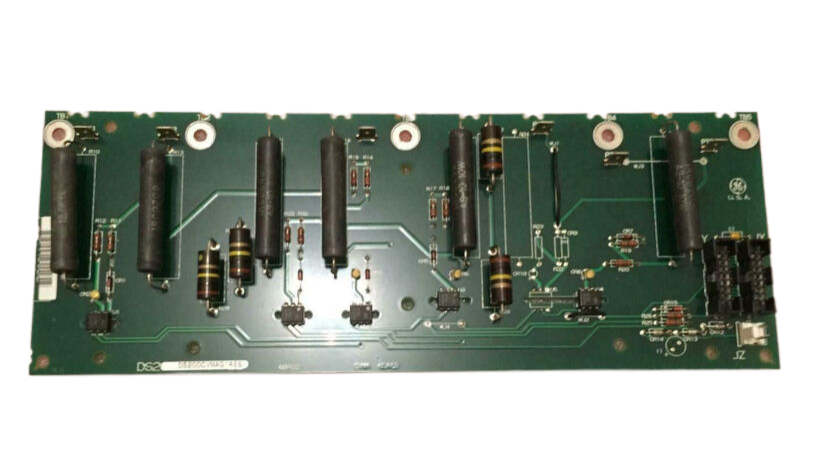

GE GE-FANUC A06B-0075-B103 SERVO MOTOR

Introducing the GE-FANUC – a pivotal advancement in the realm of industrial automation. Known for its reliability and performance, the GE-FANUC is engineered to meet the demands of various industrial applications, providing solutions that enhance efficiency and productivity. With a robust set of technical features, the GE-FANUC stands out in the competitive landscape of automation products, making it an ideal choice for businesses looking to optimize their operations.

**Key Technical Features**

The GE-FANUC is equipped with a powerful suite of technical features designed to elevate system performance. At its core, the model boasts a high-speed processing unit that ensures quick data processing and real-time operation control. With a modular design, the GE-FANUC allows for easy scalability and customization, enabling businesses to adapt the system to their unique requirements.

The GE-FANUC supports a wide range of communication protocols, facilitating seamless integration with existing systems. This feature is particularly beneficial for industries with diverse equipment and legacy systems, ensuring that operators can maintain continuity without extensive overhauls. Its compatibility with both Ethernet and serial communication enhances connectivity, providing users with the flexibility to choose the best configuration for their operations.

Moreover, the GE-FANUC is designed for durability, featuring a rugged housing that withstands harsh industrial environments. Its temperature and humidity tolerance rates ensure reliable performance in various conditions, reducing downtime and maintenance costs. With built-in diagnostic capabilities, users can swiftly identify and resolve issues, further ensuring operational efficiency.

**Usage Scenarios**

The versatility of the GE-FANUC makes it suitable for a myriad of applications across different sectors. In manufacturing, it can be utilized for automated assembly lines, enhancing production speed and accuracy. The model’s ability to integrate with robotics allows for sophisticated processes that require precision and quick response times.

In the energy sector, the GE-FANUC plays a crucial role in monitoring and controlling power distribution systems. Its real-time data processing capabilities enable operators to manage resources efficiently, ensuring optimal performance and minimal wastage. Additionally, the GE-FANUC is an excellent choice for process automation in chemical and food industries where stringent safety and quality standards must be adhered to.

Moreover, the GE-FANUC is ideal for transportation systems, where it can manage traffic control and logistics operations, optimizing flow and reducing congestion. Its adaptability ensures that the model can cater to different operational needs, making it a valuable asset in various scenarios.

**Comparison with Other Models**

When compared to other models within the GE brand, such as the GE SR750 and GE IC697MDL740, the GE-FANUC distinguishes itself through its superior processing speed and enhanced communication capabilities. While the GE SR750 is known for its robust data handling, the GE-FANUC offers more advanced features that support a broader range of applications, making it a more versatile option.

In comparison to the GE IS200DSPXH2DBD, which is tailored for specific industrial applications, the GE-FANUC provides a more comprehensive solution that can be customized for various environments. The GE IC695CPE310-ABAH, while efficient, may not offer the same level of scalability as the GE-FANUC, making the latter a more future-proof investment for businesses looking to expand.

When assessing the GE-FANUC against models like the GE DS3800HSAB or GE IS200JPDMG1ADC, it becomes clear that the GE-FANUC not only meets but exceeds the requirements of modern automation systems. Its advanced diagnostic features and modular design place it ahead of the curve, ensuring that it remains relevant in an ever-evolving technological landscape.

**Reference to Related Models**

For businesses considering the GE-FANUC, it is also important to be aware of other related models that may complement or serve as alternatives. These include the GE IC200CPU005, which is known for its compact design and efficiency in smaller applications; the GE VMIVME-7671-421000, which offers exceptional data acquisition capabilities; and the GE 469-P5-HI-A1-E-H, recognized for its protective relay functions.

Furthermore, models such as the GE IC693APU301 and the GE IC200UAL005 are excellent for those seeking specific automation functionalities, while the GE HE693RTM705 provides robust remote terminal management capabilities. The GE DS200TCDAH1BHD is another notable mention, particularly for industries requiring high-availability configurations.

For users focused on advanced process control, the GE IS200EDFFH1ABA and the GE DS200DDTBG2A are worth considering, as they bring specialized features tailored for unique operational challenges. Finally, the GE IS220PPDAH1A is a solid option for those seeking an integrated approach to process automation.

**Conclusion**

The GE-FANUC epitomizes the cutting-edge of GE automation products, offering unparalleled performance, reliability, and versatility. Its advanced technical features, adaptability across various industries, and durability in harsh environments make it an essential tool for businesses aiming to enhance their operational efficiency. By choosing the GE-FANUC, companies can invest in a future-proof solution that not only meets current needs but is also capable of evolving alongside technological advancements. With a range of related models to consider, the GE-FANUC stands as a prime candidate for those looking to elevate their automation capabilities to new heights. Embrace the future of industry with GE-FANUC, where innovation meets reliability.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The GE-FANUC is equipped with a powerful suite of technical features designed to elevate system performance. At its core, the model boasts a high-speed processing unit that ensures quick data processing and real-time operation control. With a modular design, the GE-FANUC allows for easy scalability and customization, enabling businesses to adapt the system to their unique requirements.

The GE-FANUC supports a wide range of communication protocols, facilitating seamless integration with existing systems. This feature is particularly beneficial for industries with diverse equipment and legacy systems, ensuring that operators can maintain continuity without extensive overhauls. Its compatibility with both Ethernet and serial communication enhances connectivity, providing users with the flexibility to choose the best configuration for their operations.

Moreover, the GE-FANUC is designed for durability, featuring a rugged housing that withstands harsh industrial environments. Its temperature and humidity tolerance rates ensure reliable performance in various conditions, reducing downtime and maintenance costs. With built-in diagnostic capabilities, users can swiftly identify and resolve issues, further ensuring operational efficiency.

**Usage Scenarios**

The versatility of the GE-FANUC makes it suitable for a myriad of applications across different sectors. In manufacturing, it can be utilized for automated assembly lines, enhancing production speed and accuracy. The model’s ability to integrate with robotics allows for sophisticated processes that require precision and quick response times.

In the energy sector, the GE-FANUC plays a crucial role in monitoring and controlling power distribution systems. Its real-time data processing capabilities enable operators to manage resources efficiently, ensuring optimal performance and minimal wastage. Additionally, the GE-FANUC is an excellent choice for process automation in chemical and food industries where stringent safety and quality standards must be adhered to.

Moreover, the GE-FANUC is ideal for transportation systems, where it can manage traffic control and logistics operations, optimizing flow and reducing congestion. Its adaptability ensures that the model can cater to different operational needs, making it a valuable asset in various scenarios.

**Comparison with Other Models**

When compared to other models within the GE brand, such as the GE SR750 and GE IC697MDL740, the GE-FANUC distinguishes itself through its superior processing speed and enhanced communication capabilities. While the GE SR750 is known for its robust data handling, the GE-FANUC offers more advanced features that support a broader range of applications, making it a more versatile option.

In comparison to the GE IS200DSPXH2DBD, which is tailored for specific industrial applications, the GE-FANUC provides a more comprehensive solution that can be customized for various environments. The GE IC695CPE310-ABAH, while efficient, may not offer the same level of scalability as the GE-FANUC, making the latter a more future-proof investment for businesses looking to expand.

When assessing the GE-FANUC against models like the GE DS3800HSAB or GE IS200JPDMG1ADC, it becomes clear that the GE-FANUC not only meets but exceeds the requirements of modern automation systems. Its advanced diagnostic features and modular design place it ahead of the curve, ensuring that it remains relevant in an ever-evolving technological landscape.

**Reference to Related Models**

For businesses considering the GE-FANUC, it is also important to be aware of other related models that may complement or serve as alternatives. These include the GE IC200CPU005, which is known for its compact design and efficiency in smaller applications; the GE VMIVME-7671-421000, which offers exceptional data acquisition capabilities; and the GE 469-P5-HI-A1-E-H, recognized for its protective relay functions.

Furthermore, models such as the GE IC693APU301 and the GE IC200UAL005 are excellent for those seeking specific automation functionalities, while the GE HE693RTM705 provides robust remote terminal management capabilities. The GE DS200TCDAH1BHD is another notable mention, particularly for industries requiring high-availability configurations.

For users focused on advanced process control, the GE IS200EDFFH1ABA and the GE DS200DDTBG2A are worth considering, as they bring specialized features tailored for unique operational challenges. Finally, the GE IS220PPDAH1A is a solid option for those seeking an integrated approach to process automation.

**Conclusion**

The GE-FANUC epitomizes the cutting-edge of GE automation products, offering unparalleled performance, reliability, and versatility. Its advanced technical features, adaptability across various industries, and durability in harsh environments make it an essential tool for businesses aiming to enhance their operational efficiency. By choosing the GE-FANUC, companies can invest in a future-proof solution that not only meets current needs but is also capable of evolving alongside technological advancements. With a range of related models to consider, the GE-FANUC stands as a prime candidate for those looking to elevate their automation capabilities to new heights. Embrace the future of industry with GE-FANUC, where innovation meets reliability.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.