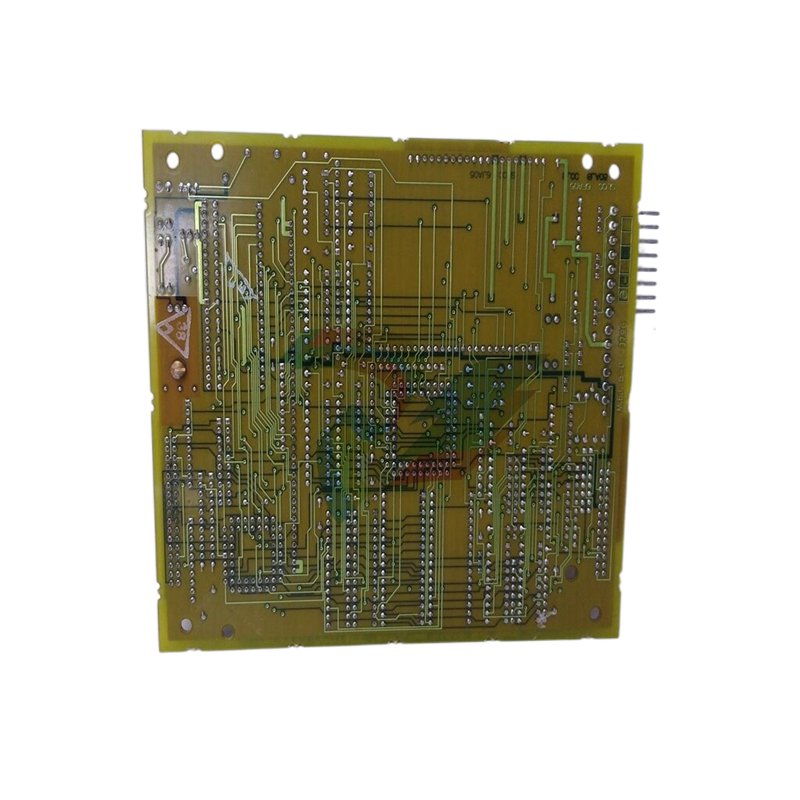

GE – GE General Electric Mark VI Circuit Board

Introducing the GE SR750: The Pinnacle of Automation Excellence

In the ever-evolving landscape of industrial automation, reliability and performance are paramount. The GE SR750 stands as a testament to GE’s commitment to innovation and quality in automation products. With its blend of cutting-edge technology and user-centric design, this model is engineered to meet the demanding requirements of various industrial applications.

**Key Technical Features**

At the heart of the GE SR750 lies its robust architecture, which supports advanced processing capabilities. It features a high-performance CPU that ensures swift data processing and real-time performance, crucial for time-sensitive applications. The SR750 boasts a modular design, allowing for easy scalability and customization. This flexibility enables users to tailor the system to specific project needs, making it suitable for diverse environments.

The SR750 is equipped with an extensive range of communication ports, including Ethernet, Serial, and Fieldbus options, ensuring seamless integration with existing systems. This versatility ensures that it can efficiently communicate with various GE automation products and other third-party devices, enhancing operational efficiency.

In addition to its communication capabilities, the GE SR750 offers advanced diagnostic tools. Users can monitor system performance in real-time, allowing for proactive maintenance and reducing downtime. The model also supports a wide input voltage range, making it adaptable to different power supply conditions, which is essential for global operations.

**Usage Scenarios**

The GE SR750 is ideal for a variety of industrial applications, including but not limited to manufacturing, oil and gas, water and wastewater management, and transportation systems. In manufacturing, the SR750 can be deployed for process automation, where precise control and monitoring of machinery are required. Its ability to integrate with sensors and actuators makes it an excellent choice for controlling assembly lines, ensuring that operations run smoothly and efficiently.

In the oil and gas sector, the SR750’s rugged design and advanced communication capabilities make it suitable for remote monitoring and control of drilling operations. Its diagnostic tools enable operators to anticipate failures before they occur, ensuring safety and reliability in environments where downtime is costly.

Water and wastewater management facilities benefit from the SR750's ability to manage complex processes, including pumping, filtration, and treatment. The model's scalability allows for easy upgrades as the facility expands or evolves, making it a long-term investment for operators.

Transportation systems can leverage the GE SR750 for traffic management and control systems. Its ability to process data in real time allows for efficient traffic flow and enhanced safety measures, making it a vital component of smart city initiatives.

**Comparison with Other Models**

When comparing the GE SR750 with other models such as the GE IC697MDL740, GE IS200DSPXH2DBD, and GE IC660BBA020, it becomes apparent that the SR750 excels in several key areas. For instance, while the IC697MDL740 is a reliable choice for basic control applications, the SR750’s advanced processing capabilities and extensive communication options provide a significant advantage for complex projects.

In contrast to the GE IS200DSPXH2DBD, which is designed primarily for specific applications, the SR750’s modular design allows for greater customization across various industries. This flexibility is a game-changer for businesses looking for a versatile solution that can adapt to changing operational demands.

The GE IC660BBA020, known for its ruggedness, is an excellent option for harsh environments. However, the SR750 combines durability with advanced technology, ensuring it not only withstands challenging conditions but also delivers superior performance.

**Related Models**

The GE SR750 is part of a comprehensive suite of GE automation products, each designed to meet diverse industrial needs. Some related models include:

1. GE SR750 – Advanced processing and communication capabilities.

2. GE IC697MDL740 – Reliable control for basic applications.

3. GE IS200DSPXH2DBD – Specialized for specific automation tasks.

4. GE IC660BBA020 – Rugged design for harsh environments.

5. GE IS200EDFFH1ABA – Offers enhanced diagnostics for critical systems.

6. GE IC200CPU005 – Ideal for smaller applications with limited complexity.

7. GE IC695CPE310-ABAH – A versatile option for mid-range automation tasks.

8. GE IS220PPDAH1A – Focused on process control and monitoring.

9. GE DS200DDTBG2A – Excellent for distributed control applications.

10. GE 469-P5-HI-A1-E-H – A comprehensive protection relay for electrical systems.

These models highlight GE's commitment to providing a broad range of automation solutions, ensuring that businesses can find the right tool for their specific needs.

**Conclusion**

The GE SR750 represents the future of industrial automation, combining advanced technology with unparalleled flexibility and reliability. Its ability to adapt to various applications across multiple industries sets it apart from competitors. For businesses seeking to enhance their operational efficiency, the SR750 is not just a choice; it is a strategic investment in automation excellence.

Whether you are in manufacturing, oil and gas, water management, or transportation, the GE SR750 is designed to elevate your operations, making it a standout among GE automation products. With its robust features and versatile applications, the SR750 is poised to become an indispensable component of modern industrial automation systems. Choose the GE SR750 and experience the difference in performance, reliability, and innovation.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the ever-evolving landscape of industrial automation, reliability and performance are paramount. The GE SR750 stands as a testament to GE’s commitment to innovation and quality in automation products. With its blend of cutting-edge technology and user-centric design, this model is engineered to meet the demanding requirements of various industrial applications.

**Key Technical Features**

At the heart of the GE SR750 lies its robust architecture, which supports advanced processing capabilities. It features a high-performance CPU that ensures swift data processing and real-time performance, crucial for time-sensitive applications. The SR750 boasts a modular design, allowing for easy scalability and customization. This flexibility enables users to tailor the system to specific project needs, making it suitable for diverse environments.

The SR750 is equipped with an extensive range of communication ports, including Ethernet, Serial, and Fieldbus options, ensuring seamless integration with existing systems. This versatility ensures that it can efficiently communicate with various GE automation products and other third-party devices, enhancing operational efficiency.

In addition to its communication capabilities, the GE SR750 offers advanced diagnostic tools. Users can monitor system performance in real-time, allowing for proactive maintenance and reducing downtime. The model also supports a wide input voltage range, making it adaptable to different power supply conditions, which is essential for global operations.

**Usage Scenarios**

The GE SR750 is ideal for a variety of industrial applications, including but not limited to manufacturing, oil and gas, water and wastewater management, and transportation systems. In manufacturing, the SR750 can be deployed for process automation, where precise control and monitoring of machinery are required. Its ability to integrate with sensors and actuators makes it an excellent choice for controlling assembly lines, ensuring that operations run smoothly and efficiently.

In the oil and gas sector, the SR750’s rugged design and advanced communication capabilities make it suitable for remote monitoring and control of drilling operations. Its diagnostic tools enable operators to anticipate failures before they occur, ensuring safety and reliability in environments where downtime is costly.

Water and wastewater management facilities benefit from the SR750's ability to manage complex processes, including pumping, filtration, and treatment. The model's scalability allows for easy upgrades as the facility expands or evolves, making it a long-term investment for operators.

Transportation systems can leverage the GE SR750 for traffic management and control systems. Its ability to process data in real time allows for efficient traffic flow and enhanced safety measures, making it a vital component of smart city initiatives.

**Comparison with Other Models**

When comparing the GE SR750 with other models such as the GE IC697MDL740, GE IS200DSPXH2DBD, and GE IC660BBA020, it becomes apparent that the SR750 excels in several key areas. For instance, while the IC697MDL740 is a reliable choice for basic control applications, the SR750’s advanced processing capabilities and extensive communication options provide a significant advantage for complex projects.

In contrast to the GE IS200DSPXH2DBD, which is designed primarily for specific applications, the SR750’s modular design allows for greater customization across various industries. This flexibility is a game-changer for businesses looking for a versatile solution that can adapt to changing operational demands.

The GE IC660BBA020, known for its ruggedness, is an excellent option for harsh environments. However, the SR750 combines durability with advanced technology, ensuring it not only withstands challenging conditions but also delivers superior performance.

**Related Models**

The GE SR750 is part of a comprehensive suite of GE automation products, each designed to meet diverse industrial needs. Some related models include:

1. GE SR750 – Advanced processing and communication capabilities.

2. GE IC697MDL740 – Reliable control for basic applications.

3. GE IS200DSPXH2DBD – Specialized for specific automation tasks.

4. GE IC660BBA020 – Rugged design for harsh environments.

5. GE IS200EDFFH1ABA – Offers enhanced diagnostics for critical systems.

6. GE IC200CPU005 – Ideal for smaller applications with limited complexity.

7. GE IC695CPE310-ABAH – A versatile option for mid-range automation tasks.

8. GE IS220PPDAH1A – Focused on process control and monitoring.

9. GE DS200DDTBG2A – Excellent for distributed control applications.

10. GE 469-P5-HI-A1-E-H – A comprehensive protection relay for electrical systems.

These models highlight GE's commitment to providing a broad range of automation solutions, ensuring that businesses can find the right tool for their specific needs.

**Conclusion**

The GE SR750 represents the future of industrial automation, combining advanced technology with unparalleled flexibility and reliability. Its ability to adapt to various applications across multiple industries sets it apart from competitors. For businesses seeking to enhance their operational efficiency, the SR750 is not just a choice; it is a strategic investment in automation excellence.

Whether you are in manufacturing, oil and gas, water management, or transportation, the GE SR750 is designed to elevate your operations, making it a standout among GE automation products. With its robust features and versatile applications, the SR750 is poised to become an indispensable component of modern industrial automation systems. Choose the GE SR750 and experience the difference in performance, reliability, and innovation.

The above parameters are for reference only. Please contact our technical team for precise selection.

.jpg)

There are no reviews yet.