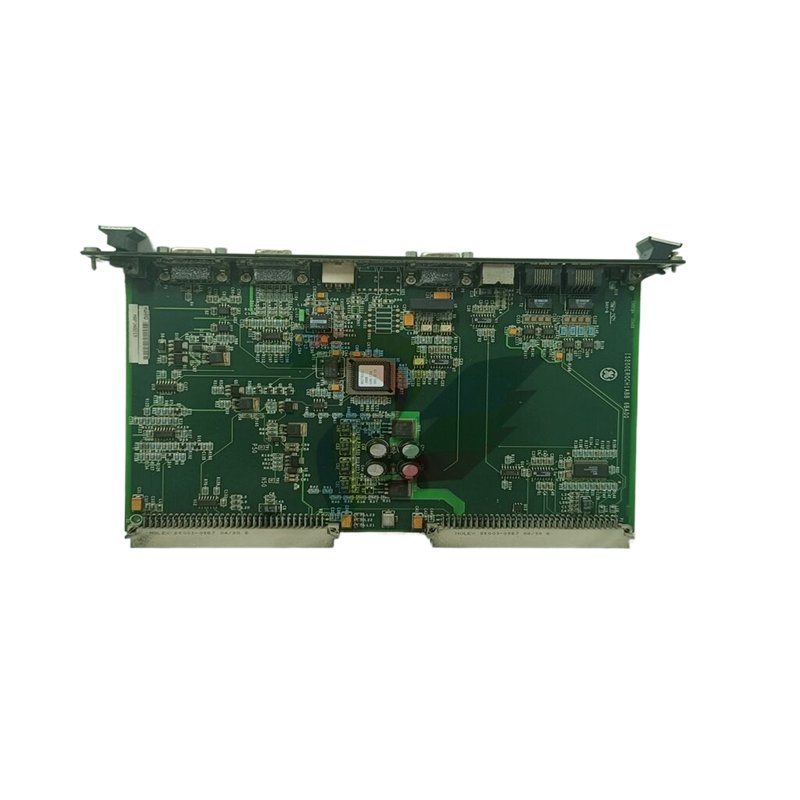

GE IC695ALG626 ANALOG INPUT HART MODULE Industrial Automation Solutions for Enhanced Efficiency

Introducing the GE IC695ALG626, a cutting-edge component designed to enhance your automation systems with precision and reliability. As part of GE's renowned line of automation products, the IC695ALG626 stands out for its robust technical features, versatile applications, and compatibility with a range of other GE models. Discover how this exceptional module can elevate your operations and streamline your processes.

Key Technical Features

The GE IC695ALG626 is an analog input module that boasts an impressive array of technical specifications. It features 16 differential input channels, allowing for simultaneous data acquisition from multiple sources, which is crucial for applications requiring real-time monitoring and control. Each channel supports a wide voltage range, accommodating input signals from 0 to 10 volts, making it highly versatile for various industrial environments.

With a high-resolution of 16 bits, the IC695ALG626 ensures accurate representation of input signals, which translates to more precise control in your automation processes. The module is designed to support both voltage and current inputs, providing flexibility in integration with existing systems. Furthermore, it is capable of handling input sampling rates of up to 1 millisecond, enabling rapid response to changes in the operational environment.

The IC695ALG626 also incorporates advanced diagnostic features, including open-circuit detection and input range monitoring. This functionality allows users to quickly identify and troubleshoot issues, minimizing downtime and ensuring seamless operation. Additionally, with the capability to communicate over Ethernet, this module integrates effortlessly with GE’s suite of automation products, providing a cohesive and efficient control solution.

Usage Scenarios

The GE IC695ALG626 is ideal for a wide range of applications across various industries, including manufacturing, oil and gas, water treatment, and building automation. In a manufacturing setting, it can be used for monitoring process variables such as temperature, pressure, and flow rates, allowing for real-time adjustments to maintain optimal performance.

In oil and gas applications, the IC695ALG626 can facilitate the monitoring of critical parameters in drilling operations, ensuring safety and efficiency while minimizing the risks associated with equipment failure. Similarly, in water treatment facilities, this module can help monitor chemical dosing and water quality parameters, ensuring compliance with regulatory standards and enhancing operational efficiency.

Furthermore, building automation systems can benefit from the IC695ALG626’s capabilities by integrating it with HVAC systems to monitor and control environmental conditions, ensuring comfort and energy efficiency. Its adaptability makes it a valuable asset in any automation strategy.

Comparison with Other Models

When comparing the GE IC695ALG626 with other models in the GE automation product line, such as the IC697MDL250 and the IS200TPROH1BCB, several key differences emerge. The IC697MDL250 is primarily a digital input/output module, which limits its application to binary signals. In contrast, the IC695ALG626’s capability to handle analog signals makes it a more versatile choice for applications requiring continuous data input and control.

Another noteworthy comparison is with the IS200TPROH1BCB, a specialized module designed for process control. While the IS200TPROH1BCB excels in specific process control tasks, the IC695ALG626 offers broader functionality, making it suitable for a wider range of applications where both analog and digital inputs are necessary.

The IC695ALG626 also provides superior resolution and sampling rates compared to older models like the IC660ELB912 and the IC670MDL640, which can enhance performance in time-sensitive applications. This module’s advanced diagnostics further set it apart from many other models, ensuring that users can maintain their systems with greater ease and confidence.

Related Models

For those considering the GE IC695ALG626, it’s beneficial to be aware of other related models that could complement or serve as alternatives in specific applications. Here are ten models worth mentioning:

1. GE IS200TBCIH1BBC – A versatile controller for various industrial applications.

2. GE IS220PPROS1B – A powerful processor for advanced control systems.

3. GE IC697MDL250 – A digital input/output module for basic control needs.

4. GE IC698CMX016 – A communication module that enhances connectivity.

5. GE IS215UCVEH2AB – A unique unit for specialized process control.

6. GE DS200CTBAG1ADD – A controller for high-performance applications.

7. GE 369-HI-0-M-0-0-0 – A highly integrated control system.

8. GE IS200TPROH1BBB – A robust process control module suitable for complex tasks.

9. GE IC670MDL740J – A digital input/output module for flexible automation solutions.

10. GE IS200DSPXH1DBC – A digital signal processing module for advanced applications.

These models, alongside the GE IC695ALG626, create a comprehensive suite of options for any automation project, allowing users to tailor their systems to meet specific needs and optimize performance.

Conclusion

The GE IC695ALG626 is an exceptional addition to the GE automation products lineup, offering a blend of high-performance features and flexible applications. With its advanced analog input capabilities, rapid response times, and robust diagnostic tools, this module is designed to meet the demands of modern industrial environments. Whether you're in manufacturing, oil and gas, water treatment, or building automation, the IC695ALG626 is poised to enhance your operations and ensure seamless control of your processes. Explore the potential of the GE IC695ALG626 today and take your automation systems to new heights.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE IC695ALG626 is an analog input module that boasts an impressive array of technical specifications. It features 16 differential input channels, allowing for simultaneous data acquisition from multiple sources, which is crucial for applications requiring real-time monitoring and control. Each channel supports a wide voltage range, accommodating input signals from 0 to 10 volts, making it highly versatile for various industrial environments.

With a high-resolution of 16 bits, the IC695ALG626 ensures accurate representation of input signals, which translates to more precise control in your automation processes. The module is designed to support both voltage and current inputs, providing flexibility in integration with existing systems. Furthermore, it is capable of handling input sampling rates of up to 1 millisecond, enabling rapid response to changes in the operational environment.

The IC695ALG626 also incorporates advanced diagnostic features, including open-circuit detection and input range monitoring. This functionality allows users to quickly identify and troubleshoot issues, minimizing downtime and ensuring seamless operation. Additionally, with the capability to communicate over Ethernet, this module integrates effortlessly with GE’s suite of automation products, providing a cohesive and efficient control solution.

Usage Scenarios

The GE IC695ALG626 is ideal for a wide range of applications across various industries, including manufacturing, oil and gas, water treatment, and building automation. In a manufacturing setting, it can be used for monitoring process variables such as temperature, pressure, and flow rates, allowing for real-time adjustments to maintain optimal performance.

In oil and gas applications, the IC695ALG626 can facilitate the monitoring of critical parameters in drilling operations, ensuring safety and efficiency while minimizing the risks associated with equipment failure. Similarly, in water treatment facilities, this module can help monitor chemical dosing and water quality parameters, ensuring compliance with regulatory standards and enhancing operational efficiency.

Furthermore, building automation systems can benefit from the IC695ALG626’s capabilities by integrating it with HVAC systems to monitor and control environmental conditions, ensuring comfort and energy efficiency. Its adaptability makes it a valuable asset in any automation strategy.

Comparison with Other Models

When comparing the GE IC695ALG626 with other models in the GE automation product line, such as the IC697MDL250 and the IS200TPROH1BCB, several key differences emerge. The IC697MDL250 is primarily a digital input/output module, which limits its application to binary signals. In contrast, the IC695ALG626’s capability to handle analog signals makes it a more versatile choice for applications requiring continuous data input and control.

Another noteworthy comparison is with the IS200TPROH1BCB, a specialized module designed for process control. While the IS200TPROH1BCB excels in specific process control tasks, the IC695ALG626 offers broader functionality, making it suitable for a wider range of applications where both analog and digital inputs are necessary.

The IC695ALG626 also provides superior resolution and sampling rates compared to older models like the IC660ELB912 and the IC670MDL640, which can enhance performance in time-sensitive applications. This module’s advanced diagnostics further set it apart from many other models, ensuring that users can maintain their systems with greater ease and confidence.

Related Models

For those considering the GE IC695ALG626, it’s beneficial to be aware of other related models that could complement or serve as alternatives in specific applications. Here are ten models worth mentioning:

1. GE IS200TBCIH1BBC – A versatile controller for various industrial applications.

2. GE IS220PPROS1B – A powerful processor for advanced control systems.

3. GE IC697MDL250 – A digital input/output module for basic control needs.

4. GE IC698CMX016 – A communication module that enhances connectivity.

5. GE IS215UCVEH2AB – A unique unit for specialized process control.

6. GE DS200CTBAG1ADD – A controller for high-performance applications.

7. GE 369-HI-0-M-0-0-0 – A highly integrated control system.

8. GE IS200TPROH1BBB – A robust process control module suitable for complex tasks.

9. GE IC670MDL740J – A digital input/output module for flexible automation solutions.

10. GE IS200DSPXH1DBC – A digital signal processing module for advanced applications.

These models, alongside the GE IC695ALG626, create a comprehensive suite of options for any automation project, allowing users to tailor their systems to meet specific needs and optimize performance.

Conclusion

The GE IC695ALG626 is an exceptional addition to the GE automation products lineup, offering a blend of high-performance features and flexible applications. With its advanced analog input capabilities, rapid response times, and robust diagnostic tools, this module is designed to meet the demands of modern industrial environments. Whether you're in manufacturing, oil and gas, water treatment, or building automation, the IC695ALG626 is poised to enhance your operations and ensure seamless control of your processes. Explore the potential of the GE IC695ALG626 today and take your automation systems to new heights.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.