GE IS210AEAAH3BKE Turbine Terminal Board Advanced Control for Industrial Applications

Introducing the GE IS210AEAAH3BKE Turbine Terminal Board, a cutting-edge component designed for enhancing the efficiency and reliability of turbine control systems. As part of GE's extensive range of automation products, the IS210AEAAH3BKE offers unparalleled performance, making it an essential asset for industrial applications where precision and durability are paramount.

**Key Technical Features**

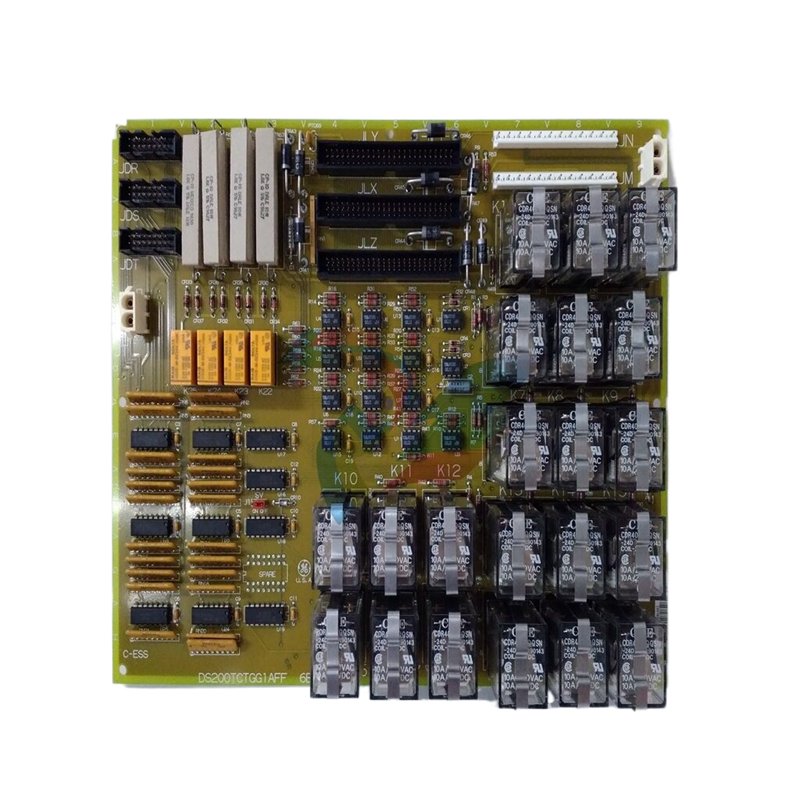

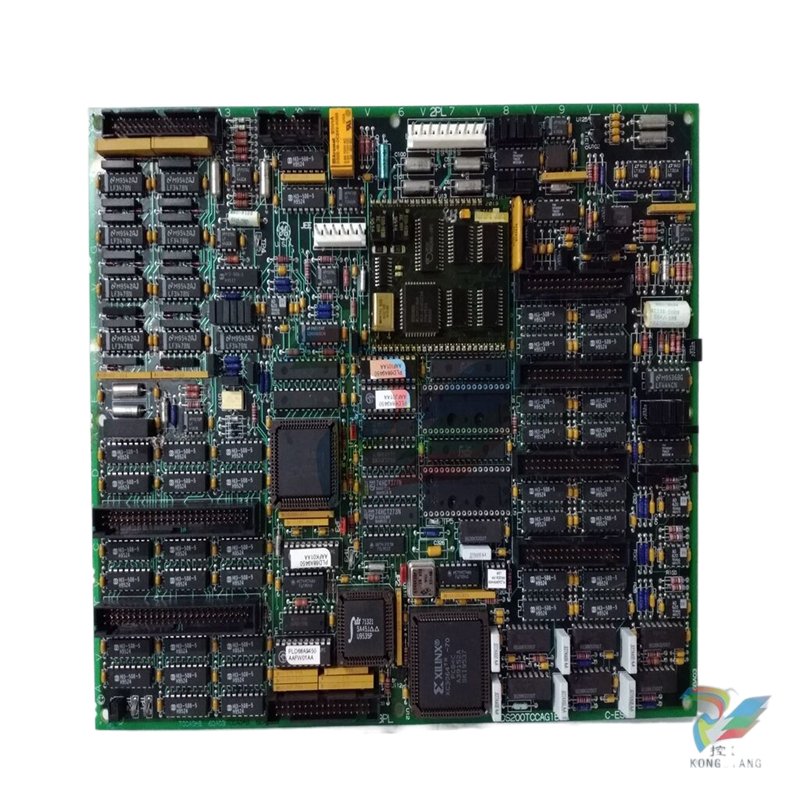

The GE IS210AEAAH3BKE Turbine Terminal Board is equipped with several key technical features that set it apart in the world of turbine control systems. It includes high-quality connectors that ensure secure and stable connections, minimizing the risk of electrical faults. This terminal board is designed for compatibility with a variety of GE automation products, providing flexibility in integration and application.

The board supports multiple input/output configurations, enabling seamless communication between various components of the turbine control system. With its robust design, the IS210AEAAH3BKE can withstand harsh environmental conditions typical of industrial settings, ensuring longevity and reliability. The board's circuitry is engineered for high efficiency, allowing for quick signal processing and effective management of turbine operations.

In addition, the GE IS210AEAAH3BKE features comprehensive diagnostic capabilities, allowing operators to monitor performance metrics and troubleshoot issues effectively. This proactive approach to maintenance reduces downtime and enhances overall operational efficiency.

**Usage Scenarios**

The GE IS210AEAAH3BKE Turbine Terminal Board is versatile and can be utilized in numerous applications within the industrial sector. It is particularly well-suited for power generation facilities, where it plays a critical role in turbine operation and control. The board can be integrated into systems that require precise monitoring and control of turbine performance, helping to optimize energy production and reduce waste.

In addition to power generation, the IS210AEAAH3BKE is ideal for use in oil and gas applications, where turbine efficiency and reliability are crucial for operational success. Its robust construction allows it to function effectively in challenging environments, including offshore platforms and remote facilities.

Moreover, this terminal board is also applicable in manufacturing settings that rely on turbine technology for operational processes. Its ability to facilitate seamless communication between various automation products makes it a valuable component in complex manufacturing systems.

**Comparison with Other Models**

When comparing the GE IS210AEAAH3BKE Turbine Terminal Board with other models in the GE lineup, it is essential to highlight its unique advantages. For instance, compared to the GE SR750 model, which focuses primarily on control logic, the IS210AEAAH3BKE provides a more comprehensive solution with enhanced connectivity and diagnostic features.

In contrast to the GE IS200DSPXH2DBD, which is designed for specific control applications, the IS210AEAAH3BKE offers broader compatibility with multiple GE automation products, making it a more versatile choice for operators looking to streamline their systems. Similarly, when placed alongside the GE IS200DSFCG1AEB, the IS210AEAAH3BKE excels in providing robust signal processing capabilities, essential for efficient turbine management.

For those considering alternatives like the GE IC695CPE310-ABAH or the GE IC200CPU005, the IS210AEAAH3BKE provides a dedicated solution specifically tailored for turbine control, which can enhance performance in turbine-centric applications.

**Related Models**

For those interested in exploring additional options within GE’s extensive lineup of automation products, consider the following related models:

1. GE IS200DSFCG1AEB – A versatile control board tailored for various GE turbine applications.

2. GE IC697MDL740 – A reliable digital I/O module that complements the IS210AEAAH3BKE in automation setups.

3. GE IS200DSPXH2DBD – A control board designed for specific applications, offering a different approach to turbine management.

4. GE IC660BBA020 – A communication board that enhances connectivity for automation products.

5. GE IS200VTURH1BAC – A turbine control board that shares some functionalities with the IS210AEAAH3BKE but focuses on different operational aspects.

6. GE DS200DDTBG2A – A diagnostics board designed for robust monitoring and troubleshooting.

7. GE IS220PPDAH1A – An I/O board that facilitates additional input and output capabilities within turbine systems.

8. GE IC693APU301 – A powerful processor module that works seamlessly with terminal boards for efficient operations.

9. GE IC695LRE001B – A logic relay that can enhance the functionality of the IS210AEAAH3BKE.

10. GE HE693RTM705 – A real-time module that provides critical timing information for turbine operations.

In conclusion, the GE IS210AEAAH3BKE Turbine Terminal Board stands out as a vital component for any industrial application relying on turbine control systems. Its robust design, comprehensive diagnostic features, and compatibility with a wide range of GE automation products make it a top choice for enhancing operational efficiency and reliability. Whether in power generation, oil and gas, or manufacturing, the IS210AEAAH3BKE is engineered to meet the demands of modern industrial environments, ensuring that your turbine operations run smoothly and efficiently.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The GE IS210AEAAH3BKE Turbine Terminal Board is equipped with several key technical features that set it apart in the world of turbine control systems. It includes high-quality connectors that ensure secure and stable connections, minimizing the risk of electrical faults. This terminal board is designed for compatibility with a variety of GE automation products, providing flexibility in integration and application.

The board supports multiple input/output configurations, enabling seamless communication between various components of the turbine control system. With its robust design, the IS210AEAAH3BKE can withstand harsh environmental conditions typical of industrial settings, ensuring longevity and reliability. The board's circuitry is engineered for high efficiency, allowing for quick signal processing and effective management of turbine operations.

In addition, the GE IS210AEAAH3BKE features comprehensive diagnostic capabilities, allowing operators to monitor performance metrics and troubleshoot issues effectively. This proactive approach to maintenance reduces downtime and enhances overall operational efficiency.

**Usage Scenarios**

The GE IS210AEAAH3BKE Turbine Terminal Board is versatile and can be utilized in numerous applications within the industrial sector. It is particularly well-suited for power generation facilities, where it plays a critical role in turbine operation and control. The board can be integrated into systems that require precise monitoring and control of turbine performance, helping to optimize energy production and reduce waste.

In addition to power generation, the IS210AEAAH3BKE is ideal for use in oil and gas applications, where turbine efficiency and reliability are crucial for operational success. Its robust construction allows it to function effectively in challenging environments, including offshore platforms and remote facilities.

Moreover, this terminal board is also applicable in manufacturing settings that rely on turbine technology for operational processes. Its ability to facilitate seamless communication between various automation products makes it a valuable component in complex manufacturing systems.

**Comparison with Other Models**

When comparing the GE IS210AEAAH3BKE Turbine Terminal Board with other models in the GE lineup, it is essential to highlight its unique advantages. For instance, compared to the GE SR750 model, which focuses primarily on control logic, the IS210AEAAH3BKE provides a more comprehensive solution with enhanced connectivity and diagnostic features.

In contrast to the GE IS200DSPXH2DBD, which is designed for specific control applications, the IS210AEAAH3BKE offers broader compatibility with multiple GE automation products, making it a more versatile choice for operators looking to streamline their systems. Similarly, when placed alongside the GE IS200DSFCG1AEB, the IS210AEAAH3BKE excels in providing robust signal processing capabilities, essential for efficient turbine management.

For those considering alternatives like the GE IC695CPE310-ABAH or the GE IC200CPU005, the IS210AEAAH3BKE provides a dedicated solution specifically tailored for turbine control, which can enhance performance in turbine-centric applications.

**Related Models**

For those interested in exploring additional options within GE’s extensive lineup of automation products, consider the following related models:

1. GE IS200DSFCG1AEB – A versatile control board tailored for various GE turbine applications.

2. GE IC697MDL740 – A reliable digital I/O module that complements the IS210AEAAH3BKE in automation setups.

3. GE IS200DSPXH2DBD – A control board designed for specific applications, offering a different approach to turbine management.

4. GE IC660BBA020 – A communication board that enhances connectivity for automation products.

5. GE IS200VTURH1BAC – A turbine control board that shares some functionalities with the IS210AEAAH3BKE but focuses on different operational aspects.

6. GE DS200DDTBG2A – A diagnostics board designed for robust monitoring and troubleshooting.

7. GE IS220PPDAH1A – An I/O board that facilitates additional input and output capabilities within turbine systems.

8. GE IC693APU301 – A powerful processor module that works seamlessly with terminal boards for efficient operations.

9. GE IC695LRE001B – A logic relay that can enhance the functionality of the IS210AEAAH3BKE.

10. GE HE693RTM705 – A real-time module that provides critical timing information for turbine operations.

In conclusion, the GE IS210AEAAH3BKE Turbine Terminal Board stands out as a vital component for any industrial application relying on turbine control systems. Its robust design, comprehensive diagnostic features, and compatibility with a wide range of GE automation products make it a top choice for enhancing operational efficiency and reliability. Whether in power generation, oil and gas, or manufacturing, the IS210AEAAH3BKE is engineered to meet the demands of modern industrial environments, ensuring that your turbine operations run smoothly and efficiently.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.