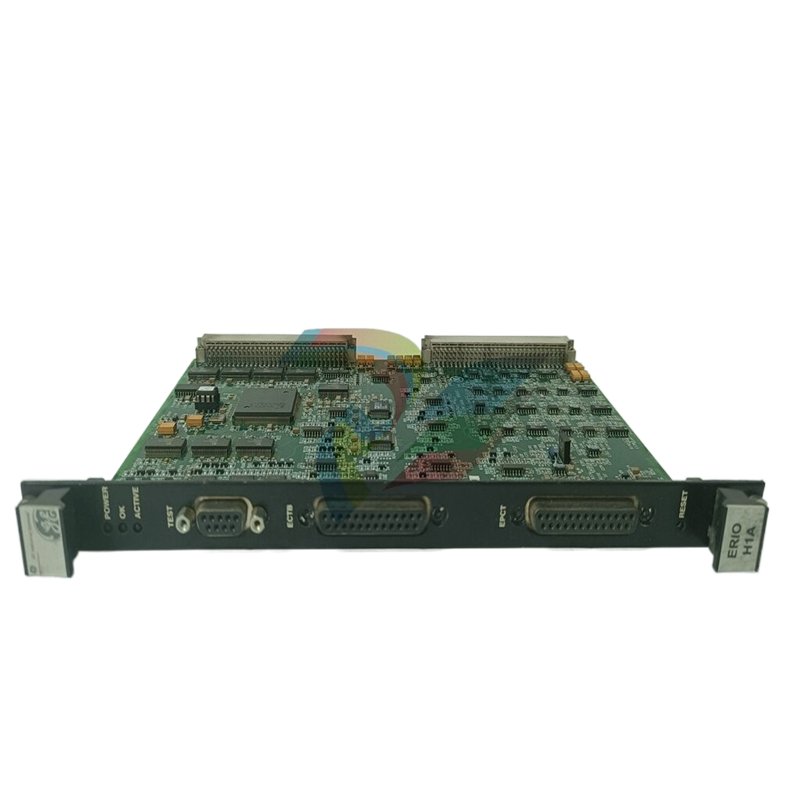

GE IS220PPDAH1A REV E Industrial PLC I/O Pack

Introducing the GE IS220PPDAH1A, a cutting-edge component within the GE automation products lineup, designed to elevate your industrial control systems to new heights. This model serves as a versatile and reliable solution, perfect for a myriad of applications. The IS220PPDAH1A integrates seamlessly into existing infrastructures while providing enhanced performance and efficiency.

Key Technical Features

The GE IS220PPDAH1A features a robust architecture that supports high-level processing and communication capabilities. Built with advanced technology, it boasts a high-speed processor that ensures rapid data handling and real-time processing, which is essential for time-sensitive applications. The model supports multiple I/O configurations, enabling flexibility in system design. Additionally, its compatibility with various GE automation products allows for easy integration and scalability.

One of the standout features of the IS220PPDAH1A is its extensive diagnostics capabilities. This model provides comprehensive monitoring to facilitate proactive maintenance, reducing downtime and operational costs. The intuitive user interface enhances usability, allowing operators to access critical system information quickly. Moreover, the IS220PPDAH1A supports various communication protocols, ensuring seamless connectivity with other devices and systems. Its robust design is also optimized for harsh industrial environments, making it an ideal choice for factories, oil and gas facilities, and power generation plants.

Usage Scenarios

The GE IS220PPDAH1A is designed for a wide range of applications across various industries. Its adaptability makes it suitable for process automation, machine control, and data acquisition systems. For instance, in manufacturing environments, this model can be utilized to monitor and control production lines, ensuring optimized performance and minimizing waste. In the energy sector, the IS220PPDAH1A can be employed to monitor turbine operations and facilitate communication between various control systems, thus enhancing overall efficiency and reliability.

Moreover, the IS220PPDAH1A shines in complex process control applications, such as chemical processing or water treatment facilities. Here, it can manage multiple inputs and outputs, ensuring precise control over critical parameters. The model's advanced diagnostics and monitoring capabilities allow operators to quickly identify and rectify any issues, significantly enhancing system reliability and productivity.

Comparison with Other Models

When comparing the GE IS220PPDAH1A with other models within the GE automation products portfolio, such as the GE IS220PPROS1B and GE IS220PRTDH1A, several key differences become evident. While the IS220PPDAH1A focuses on high-speed processing and extensive diagnostics, the IS220PPROS1B is tailored for specific process applications, providing a more specialized approach. Meanwhile, the IS220PRTDH1A emphasizes temperature and pressure monitoring, making it ideal for conditions where environmental parameters are critical.

Additionally, the IS220PPDAH1A stands out in terms of flexibility and compatibility with other GE products. For instance, when compared to models like the GE IS200TBCIH1BBC or the GE DS200TCQAG1BHF, the IS220PPDAH1A’s versatile I/O capabilities and communication options provide a significant advantage, enabling integration into a broader range of systems and applications.

Related Models

In the realm of automation solutions, understanding the breadth of available products can help in making informed decisions. Here are ten related models that complement the GE IS220PPDAH1A:

1. GE IS200TBCIH1BBC – A versatile controller for various industrial applications.

2. GE IS220PPROS1B – Specifically designed for process control applications.

3. GE IS220PRTDH1A – Ideal for temperature and pressure monitoring tasks.

4. GE IS200TPROH1BBB – Focused on advanced processing tasks in control systems.

5. GE IS200DSPXH1DBC – A digital signal processing unit for enhanced data handling.

6. GE IS230SNIDH1A – Designed for networked control systems.

7. GE IS215UCVEH2AB – A controller for complex machine operations.

8. GE DS200CTBAG1ADD – A control board for turbine applications.

9. GE IC697MDL250 – A modular input/output unit for automation setups.

10. GE IC660ELB912G – An Ethernet link board for robust communication capabilities.

These models, along with the GE IS220PPDAH1A, form a comprehensive ecosystem of GE automation products, allowing for tailored solutions to meet specific industrial needs.

In conclusion, the GE IS220PPDAH1A is a powerful and versatile addition to the GE automation products range, offering unparalleled performance, reliability, and flexibility. Its advanced features make it suitable for a wide array of applications, from manufacturing to energy management. By choosing the IS220PPDAH1A, businesses can ensure they are equipped with the latest technology to meet the demands of today’s competitive industrial landscape, ultimately driving efficiency and productivity to new levels.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE IS220PPDAH1A features a robust architecture that supports high-level processing and communication capabilities. Built with advanced technology, it boasts a high-speed processor that ensures rapid data handling and real-time processing, which is essential for time-sensitive applications. The model supports multiple I/O configurations, enabling flexibility in system design. Additionally, its compatibility with various GE automation products allows for easy integration and scalability.

One of the standout features of the IS220PPDAH1A is its extensive diagnostics capabilities. This model provides comprehensive monitoring to facilitate proactive maintenance, reducing downtime and operational costs. The intuitive user interface enhances usability, allowing operators to access critical system information quickly. Moreover, the IS220PPDAH1A supports various communication protocols, ensuring seamless connectivity with other devices and systems. Its robust design is also optimized for harsh industrial environments, making it an ideal choice for factories, oil and gas facilities, and power generation plants.

Usage Scenarios

The GE IS220PPDAH1A is designed for a wide range of applications across various industries. Its adaptability makes it suitable for process automation, machine control, and data acquisition systems. For instance, in manufacturing environments, this model can be utilized to monitor and control production lines, ensuring optimized performance and minimizing waste. In the energy sector, the IS220PPDAH1A can be employed to monitor turbine operations and facilitate communication between various control systems, thus enhancing overall efficiency and reliability.

Moreover, the IS220PPDAH1A shines in complex process control applications, such as chemical processing or water treatment facilities. Here, it can manage multiple inputs and outputs, ensuring precise control over critical parameters. The model's advanced diagnostics and monitoring capabilities allow operators to quickly identify and rectify any issues, significantly enhancing system reliability and productivity.

Comparison with Other Models

When comparing the GE IS220PPDAH1A with other models within the GE automation products portfolio, such as the GE IS220PPROS1B and GE IS220PRTDH1A, several key differences become evident. While the IS220PPDAH1A focuses on high-speed processing and extensive diagnostics, the IS220PPROS1B is tailored for specific process applications, providing a more specialized approach. Meanwhile, the IS220PRTDH1A emphasizes temperature and pressure monitoring, making it ideal for conditions where environmental parameters are critical.

Additionally, the IS220PPDAH1A stands out in terms of flexibility and compatibility with other GE products. For instance, when compared to models like the GE IS200TBCIH1BBC or the GE DS200TCQAG1BHF, the IS220PPDAH1A’s versatile I/O capabilities and communication options provide a significant advantage, enabling integration into a broader range of systems and applications.

Related Models

In the realm of automation solutions, understanding the breadth of available products can help in making informed decisions. Here are ten related models that complement the GE IS220PPDAH1A:

1. GE IS200TBCIH1BBC – A versatile controller for various industrial applications.

2. GE IS220PPROS1B – Specifically designed for process control applications.

3. GE IS220PRTDH1A – Ideal for temperature and pressure monitoring tasks.

4. GE IS200TPROH1BBB – Focused on advanced processing tasks in control systems.

5. GE IS200DSPXH1DBC – A digital signal processing unit for enhanced data handling.

6. GE IS230SNIDH1A – Designed for networked control systems.

7. GE IS215UCVEH2AB – A controller for complex machine operations.

8. GE DS200CTBAG1ADD – A control board for turbine applications.

9. GE IC697MDL250 – A modular input/output unit for automation setups.

10. GE IC660ELB912G – An Ethernet link board for robust communication capabilities.

These models, along with the GE IS220PPDAH1A, form a comprehensive ecosystem of GE automation products, allowing for tailored solutions to meet specific industrial needs.

In conclusion, the GE IS220PPDAH1A is a powerful and versatile addition to the GE automation products range, offering unparalleled performance, reliability, and flexibility. Its advanced features make it suitable for a wide array of applications, from manufacturing to energy management. By choosing the IS220PPDAH1A, businesses can ensure they are equipped with the latest technology to meet the demands of today’s competitive industrial landscape, ultimately driving efficiency and productivity to new levels.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.