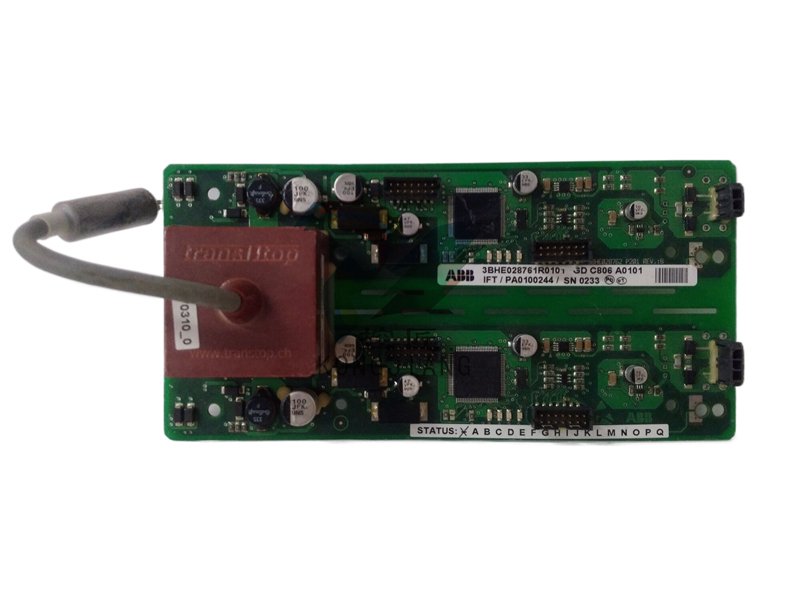

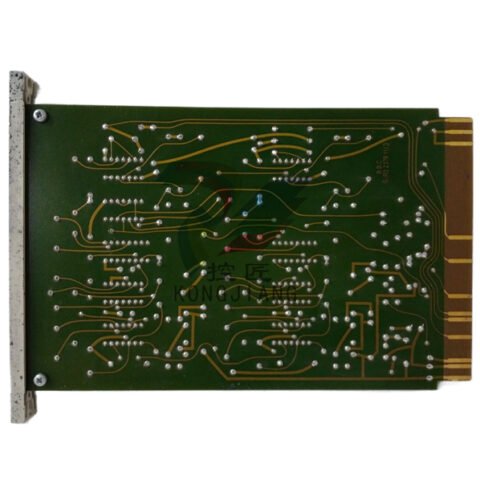

ABB IRB52 PDB02 Power Module – High-Efficiency Control Solution

Introducing the ABB IRB52 PDB02: Precision, Performance, and Versatility in Automation

In the world of industrial automation, the ABB IRB52 PDB02 sets a new benchmark for efficiency, flexibility, and precision. As part of ABB's extensive portfolio of automation products, this advanced robotic solution is engineered to meet the demands of modern manufacturing processes with unparalleled performance.

Key Technical Features

The ABB IRB52 PDB02 is a cutting-edge robotic arm designed for a wide range of applications, from assembly and material handling to packaging and quality inspection. Some of its standout technical features include:

1. **High Payload Capacity**: The IRB52 PDB02 boasts an impressive payload capacity, allowing it to handle heavy loads with ease. This capability is vital for industries that require robust handling of materials and components.

2. **Compact Design**: Its compact structure minimizes the required floor space while maximizing reach and flexibility, making it an ideal choice for tight manufacturing environments.

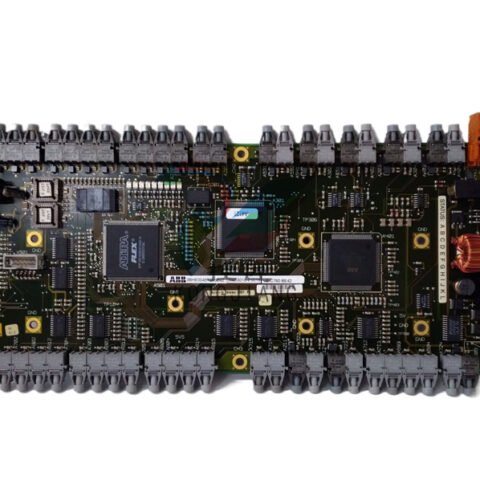

3. **Advanced Control System**: Equipped with ABB's state-of-the-art control technology, the IRB52 PDB02 offers exceptional precision and smooth operation, ensuring that tasks are performed accurately and efficiently.

4. **Versatile End-Effector Options**: The robotic arm supports various end-effector configurations, allowing for adaptability in different applications. Whether it's gripping, welding, or painting, the IRB52 PDB02 can be customized to suit specific operational needs.

5. **Integrated Safety Features**: Safety is paramount in any industrial setting. The IRB52 PDB02 comes with built-in safety features and compliance with international safety standards, ensuring that it operates securely alongside human workers.

6. **User-Friendly Programming Interface**: With ABB's intuitive programming environment, users can quickly and easily set up and modify the robotic operations, reducing the time required for deployment and increasing overall productivity.

Usage Scenarios

The ABB IRB52 PDB02 is incredibly versatile and can be employed across various industries and applications. Here are just a few scenarios where this robotic solution excels:

– **Automotive Manufacturing**: In automotive assembly lines, the IRB52 PDB02 can be utilized for tasks such as component assembly, welding, and quality inspections. Its high precision and payload capacity ensure that even complex assemblies are completed with accuracy.

– **Electronics Production**: The compact design of the IRB52 PDB02 makes it perfect for electronics manufacturing, where space is often limited. It can handle delicate components and perform intricate assembly tasks with ease.

– **Food and Beverage**: In the food industry, the ABB IRB52 PDB02 can be used for packaging, sorting, and palletizing tasks. Its hygienic design and compliance with food safety standards make it suitable for use in production lines.

– **Logistics and Warehousing**: As e-commerce continues to grow, the demand for efficient logistics solutions increases. The IRB52 PDB02 can automate material handling processes, including picking, sorting, and loading, streamlining warehouse operations.

– **Pharmaceuticals**: In pharmaceutical manufacturing, precision and compliance are crucial. The IRB52 PDB02 excels in tasks such as packaging and assembly of pharmaceutical products, ensuring that standards are met without compromising efficiency.

Comparison with Other Models

Compared to other models in ABB's extensive lineup, such as the ABB IRB 2600 or the ABB IRB 2400/1403/CR3, the IRB52 PDB02 stands out due to its unique combination of payload capacity and compact design. While the IRB 2600 is known for its versatility in medium payload applications, the IRB52 PDB02 offers a more robust solution for heavier loads without sacrificing space efficiency.

In contrast to the ABB IRB140 Series, which is optimized for high-speed applications, the IRB52 PDB02 is tailored for scenarios where payload strength and precision are of utmost importance. This makes it a superior choice for industries requiring both durability and accuracy.

Related Models

To provide a broader context, here are ten related models within the ABB automation products range that complement the IRB52 PDB02:

1. **ABB IRB 2400/1403/CR3**: Known for its speed, ideal for high-speed applications.

2. **ABB IRB 2600**: Versatile and highly adaptable for medium payload tasks.

3. **ABB IRB140 Series**: Focused on high-speed operations with a smaller footprint.

4. **ABB UNS1860B-P**: A robust model designed for heavy industrial applications.

5. **ABB PM511V16 3BSE011181R1**: A control module that enhances system integration.

6. **ABB SDCS-PIN-51 | 3BSE004940R1**: A safety module ensuring operational security.

7. **ABB 3HAC16035-1**: A powerful drive for enhanced performance in automation.

8. **ABB TU852 S800 I/O**: A modular I/O system for flexible integration.

9. **ABB ACS880-01-246A-3 3ABD00035954-D**: A versatile drive for various automation tasks.

10. **ABB GINT5611C**: An intelligent device for data communication in automation systems.

In conclusion, the ABB IRB52 PDB02 is a formidable addition to ABB's range of automation products, combining high payload capacity, compact design, and advanced control technology. Its versatility across various industries, coupled with its ability to integrate seamlessly with other ABB solutions, makes it an exceptional choice for businesses aiming to optimize their manufacturing processes. Choose the ABB IRB52 PDB02 and experience the future of automation today.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation, the ABB IRB52 PDB02 sets a new benchmark for efficiency, flexibility, and precision. As part of ABB's extensive portfolio of automation products, this advanced robotic solution is engineered to meet the demands of modern manufacturing processes with unparalleled performance.

Key Technical Features

The ABB IRB52 PDB02 is a cutting-edge robotic arm designed for a wide range of applications, from assembly and material handling to packaging and quality inspection. Some of its standout technical features include:

1. **High Payload Capacity**: The IRB52 PDB02 boasts an impressive payload capacity, allowing it to handle heavy loads with ease. This capability is vital for industries that require robust handling of materials and components.

2. **Compact Design**: Its compact structure minimizes the required floor space while maximizing reach and flexibility, making it an ideal choice for tight manufacturing environments.

3. **Advanced Control System**: Equipped with ABB's state-of-the-art control technology, the IRB52 PDB02 offers exceptional precision and smooth operation, ensuring that tasks are performed accurately and efficiently.

4. **Versatile End-Effector Options**: The robotic arm supports various end-effector configurations, allowing for adaptability in different applications. Whether it's gripping, welding, or painting, the IRB52 PDB02 can be customized to suit specific operational needs.

5. **Integrated Safety Features**: Safety is paramount in any industrial setting. The IRB52 PDB02 comes with built-in safety features and compliance with international safety standards, ensuring that it operates securely alongside human workers.

6. **User-Friendly Programming Interface**: With ABB's intuitive programming environment, users can quickly and easily set up and modify the robotic operations, reducing the time required for deployment and increasing overall productivity.

Usage Scenarios

The ABB IRB52 PDB02 is incredibly versatile and can be employed across various industries and applications. Here are just a few scenarios where this robotic solution excels:

– **Automotive Manufacturing**: In automotive assembly lines, the IRB52 PDB02 can be utilized for tasks such as component assembly, welding, and quality inspections. Its high precision and payload capacity ensure that even complex assemblies are completed with accuracy.

– **Electronics Production**: The compact design of the IRB52 PDB02 makes it perfect for electronics manufacturing, where space is often limited. It can handle delicate components and perform intricate assembly tasks with ease.

– **Food and Beverage**: In the food industry, the ABB IRB52 PDB02 can be used for packaging, sorting, and palletizing tasks. Its hygienic design and compliance with food safety standards make it suitable for use in production lines.

– **Logistics and Warehousing**: As e-commerce continues to grow, the demand for efficient logistics solutions increases. The IRB52 PDB02 can automate material handling processes, including picking, sorting, and loading, streamlining warehouse operations.

– **Pharmaceuticals**: In pharmaceutical manufacturing, precision and compliance are crucial. The IRB52 PDB02 excels in tasks such as packaging and assembly of pharmaceutical products, ensuring that standards are met without compromising efficiency.

Comparison with Other Models

Compared to other models in ABB's extensive lineup, such as the ABB IRB 2600 or the ABB IRB 2400/1403/CR3, the IRB52 PDB02 stands out due to its unique combination of payload capacity and compact design. While the IRB 2600 is known for its versatility in medium payload applications, the IRB52 PDB02 offers a more robust solution for heavier loads without sacrificing space efficiency.

In contrast to the ABB IRB140 Series, which is optimized for high-speed applications, the IRB52 PDB02 is tailored for scenarios where payload strength and precision are of utmost importance. This makes it a superior choice for industries requiring both durability and accuracy.

Related Models

To provide a broader context, here are ten related models within the ABB automation products range that complement the IRB52 PDB02:

1. **ABB IRB 2400/1403/CR3**: Known for its speed, ideal for high-speed applications.

2. **ABB IRB 2600**: Versatile and highly adaptable for medium payload tasks.

3. **ABB IRB140 Series**: Focused on high-speed operations with a smaller footprint.

4. **ABB UNS1860B-P**: A robust model designed for heavy industrial applications.

5. **ABB PM511V16 3BSE011181R1**: A control module that enhances system integration.

6. **ABB SDCS-PIN-51 | 3BSE004940R1**: A safety module ensuring operational security.

7. **ABB 3HAC16035-1**: A powerful drive for enhanced performance in automation.

8. **ABB TU852 S800 I/O**: A modular I/O system for flexible integration.

9. **ABB ACS880-01-246A-3 3ABD00035954-D**: A versatile drive for various automation tasks.

10. **ABB GINT5611C**: An intelligent device for data communication in automation systems.

In conclusion, the ABB IRB52 PDB02 is a formidable addition to ABB's range of automation products, combining high payload capacity, compact design, and advanced control technology. Its versatility across various industries, coupled with its ability to integrate seamlessly with other ABB solutions, makes it an exceptional choice for businesses aiming to optimize their manufacturing processes. Choose the ABB IRB52 PDB02 and experience the future of automation today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.