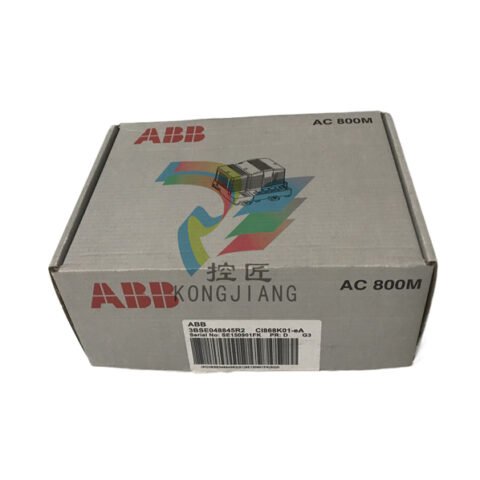

ABB TB845 Redundant Bus Outlet for Industrial Control Systems

Introducing the ABB TB845: the Pinnacle of Automation Excellence

The ABB TB845 stands as a testament to ABB's commitment to delivering innovative automation products that empower industries to enhance productivity, efficiency, and reliability. With its advanced features and robust design, the TB845 is engineered to meet the evolving needs of modern industrial applications, making it an indispensable tool for engineers and facility managers alike.

Key Technical Features

The ABB TB845 is packed with a suite of features that cater to various automation needs. Its compact design allows for seamless integration into existing systems, while its high-performance capabilities ensure optimal operation in demanding environments. Here are some of its key technical features:

1. **Versatile Input/Output Configuration**: The TB845 supports a wide range of I/O configurations, allowing users to customize setups according to specific application requirements. This flexibility ensures that it can handle various sensors, actuators, and other devices effortlessly.

2. **Robust Communication Protocols**: Equipped with multiple communication protocols such as Ethernet/IP, Modbus TCP, and Profibus, the TB845 facilitates smooth data exchange between devices and systems. This interoperability enhances system integration and promotes real-time data monitoring.

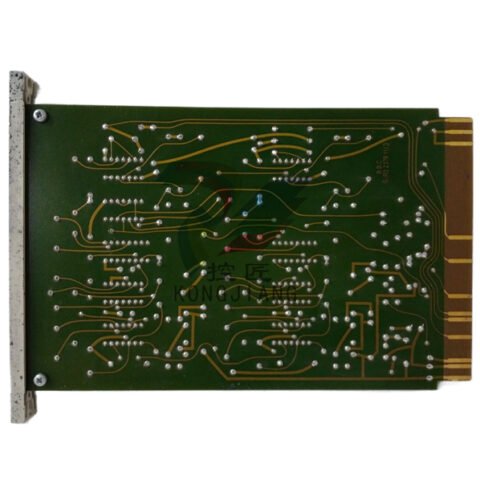

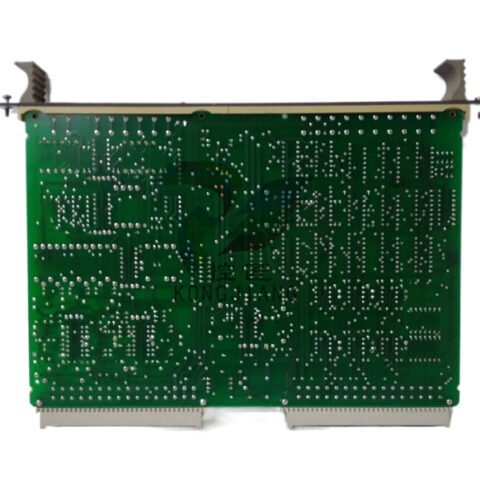

3. **High Reliability and Durability**: Designed to operate in harsh industrial conditions, the TB845 features rugged construction and components that provide exceptional durability. This ensures long-term reliability, reducing maintenance costs and downtime.

4. **User-Friendly Interface**: The TB845 comes with an intuitive user interface that simplifies setup and operation. Its graphical display provides real-time monitoring and diagnostics, enabling users to troubleshoot issues quickly and efficiently.

5. **Enhanced Safety Features**: With built-in safety protocols, the ABB TB845 ensures compliance with industry standards. These features safeguard both personnel and equipment, making it suitable for applications where safety is paramount.

Usage Scenarios

The versatility of the ABB TB845 makes it suitable for a myriad of usage scenarios across various industries. Whether you're in manufacturing, energy, or transportation, the TB845 can adapt to your needs. Here are some typical applications:

1. **Manufacturing Automation**: The TB845 can streamline production processes by automating machinery, reducing human error, and increasing output efficiency. Its robust I/O configuration allows for easy integration with existing manufacturing systems.

2. **Process Control**: In chemical and petrochemical industries, the TB845 can monitor and control process parameters, ensuring consistency and quality in production. Its real-time data capabilities allow for immediate adjustments, optimizing overall process performance.

3. **Building Management Systems**: The TB845 is ideal for use in smart buildings, where it can manage HVAC systems, lighting, and security protocols. Its communication capabilities enable seamless interaction with various building management technologies.

4. **Energy Management**: By integrating the TB845 into energy management systems, organizations can monitor energy usage, optimize consumption, and reduce costs. Its data analytics features help identify trends and make informed decisions.

5. **Transportation Systems**: The TB845 can be utilized in traffic control and public transport systems, where it can manage signals, monitor vehicle flow, and ensure safe operations.

Comparison with Other Models

When comparing the ABB TB845 with other models in the ABB portfolio, it becomes evident that the TB845 is designed for a wide array of applications while maintaining a competitive edge in performance and versatility.

For instance, the ABB TB852, while offering similar communication capabilities, is more specialized for specific industrial tasks and may not provide the same level of flexibility as the TB845. On the other hand, models like the ABB TU841 and ABB TU852 S800 I/O focus on specific input/output needs and may lack the broader functionality that the TB845 provides.

In contrast, models such as the ABB PM864AK01 and ABB PM511V16 are geared more towards specific process control applications, emphasizing computational power over I/O adaptability. The TB845’s ability to bridge various requirements makes it a more versatile choice for many users.

Related Models

To give a broader context for potential users, here are ten related models that complement the ABB TB845:

1. **ABB UNS1860B-P**: A reliable option for standard automation tasks.

2. **ABB PPE100A 3BHE037824R0101**: Ideal for power monitoring applications.

3. **ABB TU852 S800 I/O**: Focused on I/O operations with specific functionalities.

4. **ABB TB852 3BSC950263R1**: A close relative with enhanced input/output capabilities.

5. **ABB PM511V16 3BSE011181R1**: A robust solution for process control.

6. **ABB SDCS-PIN-51 3BSE004940R1**: Designed for safety-critical applications.

7. **ABB ACS880-01-246A-3 3ABD00035954-D**: A high-performance drive controller.

8. **ABB DSQC352B**: A versatile option for robotics integration.

9. **ABB 3HAC027569-001**: A reliable automation product for various control tasks.

10. **ABB IRB 2600**: A powerful robot controller for industrial applications.

SEO Keywords

In summary, the ABB TB845 is a premier choice among ABB automation products, offering unmatched flexibility, performance, and reliability across diverse industrial applications. Its extensive features, coupled with its ability to integrate seamlessly with existing systems, make it a vital component for any organization looking to enhance its automation capabilities. By choosing the ABB TB845, you are investing in a future-ready solution that can adapt to your evolving needs, ensuring your operations remain at the forefront of industrial innovation.

The above parameters are for reference only. Please contact our technical team for precise selection.

The ABB TB845 stands as a testament to ABB's commitment to delivering innovative automation products that empower industries to enhance productivity, efficiency, and reliability. With its advanced features and robust design, the TB845 is engineered to meet the evolving needs of modern industrial applications, making it an indispensable tool for engineers and facility managers alike.

Key Technical Features

The ABB TB845 is packed with a suite of features that cater to various automation needs. Its compact design allows for seamless integration into existing systems, while its high-performance capabilities ensure optimal operation in demanding environments. Here are some of its key technical features:

1. **Versatile Input/Output Configuration**: The TB845 supports a wide range of I/O configurations, allowing users to customize setups according to specific application requirements. This flexibility ensures that it can handle various sensors, actuators, and other devices effortlessly.

2. **Robust Communication Protocols**: Equipped with multiple communication protocols such as Ethernet/IP, Modbus TCP, and Profibus, the TB845 facilitates smooth data exchange between devices and systems. This interoperability enhances system integration and promotes real-time data monitoring.

3. **High Reliability and Durability**: Designed to operate in harsh industrial conditions, the TB845 features rugged construction and components that provide exceptional durability. This ensures long-term reliability, reducing maintenance costs and downtime.

4. **User-Friendly Interface**: The TB845 comes with an intuitive user interface that simplifies setup and operation. Its graphical display provides real-time monitoring and diagnostics, enabling users to troubleshoot issues quickly and efficiently.

5. **Enhanced Safety Features**: With built-in safety protocols, the ABB TB845 ensures compliance with industry standards. These features safeguard both personnel and equipment, making it suitable for applications where safety is paramount.

Usage Scenarios

The versatility of the ABB TB845 makes it suitable for a myriad of usage scenarios across various industries. Whether you're in manufacturing, energy, or transportation, the TB845 can adapt to your needs. Here are some typical applications:

1. **Manufacturing Automation**: The TB845 can streamline production processes by automating machinery, reducing human error, and increasing output efficiency. Its robust I/O configuration allows for easy integration with existing manufacturing systems.

2. **Process Control**: In chemical and petrochemical industries, the TB845 can monitor and control process parameters, ensuring consistency and quality in production. Its real-time data capabilities allow for immediate adjustments, optimizing overall process performance.

3. **Building Management Systems**: The TB845 is ideal for use in smart buildings, where it can manage HVAC systems, lighting, and security protocols. Its communication capabilities enable seamless interaction with various building management technologies.

4. **Energy Management**: By integrating the TB845 into energy management systems, organizations can monitor energy usage, optimize consumption, and reduce costs. Its data analytics features help identify trends and make informed decisions.

5. **Transportation Systems**: The TB845 can be utilized in traffic control and public transport systems, where it can manage signals, monitor vehicle flow, and ensure safe operations.

Comparison with Other Models

When comparing the ABB TB845 with other models in the ABB portfolio, it becomes evident that the TB845 is designed for a wide array of applications while maintaining a competitive edge in performance and versatility.

For instance, the ABB TB852, while offering similar communication capabilities, is more specialized for specific industrial tasks and may not provide the same level of flexibility as the TB845. On the other hand, models like the ABB TU841 and ABB TU852 S800 I/O focus on specific input/output needs and may lack the broader functionality that the TB845 provides.

In contrast, models such as the ABB PM864AK01 and ABB PM511V16 are geared more towards specific process control applications, emphasizing computational power over I/O adaptability. The TB845’s ability to bridge various requirements makes it a more versatile choice for many users.

Related Models

To give a broader context for potential users, here are ten related models that complement the ABB TB845:

1. **ABB UNS1860B-P**: A reliable option for standard automation tasks.

2. **ABB PPE100A 3BHE037824R0101**: Ideal for power monitoring applications.

3. **ABB TU852 S800 I/O**: Focused on I/O operations with specific functionalities.

4. **ABB TB852 3BSC950263R1**: A close relative with enhanced input/output capabilities.

5. **ABB PM511V16 3BSE011181R1**: A robust solution for process control.

6. **ABB SDCS-PIN-51 3BSE004940R1**: Designed for safety-critical applications.

7. **ABB ACS880-01-246A-3 3ABD00035954-D**: A high-performance drive controller.

8. **ABB DSQC352B**: A versatile option for robotics integration.

9. **ABB 3HAC027569-001**: A reliable automation product for various control tasks.

10. **ABB IRB 2600**: A powerful robot controller for industrial applications.

SEO Keywords

In summary, the ABB TB845 is a premier choice among ABB automation products, offering unmatched flexibility, performance, and reliability across diverse industrial applications. Its extensive features, coupled with its ability to integrate seamlessly with existing systems, make it a vital component for any organization looking to enhance its automation capabilities. By choosing the ABB TB845, you are investing in a future-ready solution that can adapt to your evolving needs, ensuring your operations remain at the forefront of industrial innovation.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.