BENTLY Nevada 330103-00-07-10-01-05 | Advanced Proximity Probe | Industrial Automation Solutions

Introducing the BENTLY Nevada: Your Premier Solution for Condition Monitoring and Asset Management

The BENTLY Nevada series stands as a hallmark of reliability and precision in the world of industrial automation. Renowned for its advanced technology and robust performance, the BENTLY Nevada is engineered to deliver unparalleled monitoring capabilities for critical machinery in various industries. This product is part of a comprehensive range of BENTLY automation products, designed to enhance operational efficiency and mitigate risks associated with equipment failure.

Key Technical Features

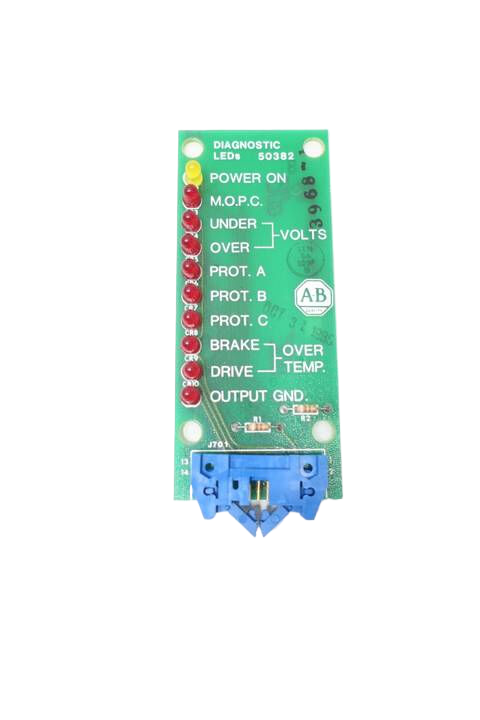

The BENTLY Nevada is equipped with a suite of technical features that set it apart from the competition. At its core, the system boasts a high-performance architecture that supports real-time data acquisition and analysis. This allows for continuous monitoring of machine health, ensuring that potential issues are identified before they escalate into costly downtime.

1. **Advanced Vibration Monitoring**: Utilizing sophisticated algorithms, the BENTLY Nevada provides precise vibration analysis, enabling users to detect anomalies and predict failures in rotating machinery.

2. **Flexible Configuration Options**: The system supports a wide variety of input channels and configurations, accommodating different sensor types and installation requirements. This adaptability makes it suitable for various applications, from turbines and compressors to pumps and motors.

3. **User-Friendly Interface**: The BENTLY Nevada features an intuitive user interface that simplifies navigation and data interpretation. Operators can easily access real-time insights and historical data, making it easier to make informed decisions.

4. **Integrated Diagnostics**: With built-in diagnostic capabilities, the BENTLY Nevada offers detailed reports and alerts, enabling users to address issues proactively and maintain optimal performance levels.

5. **Scalability**: As your operations grow, the BENTLY Nevada can seamlessly integrate with additional sensors and systems, providing a scalable solution for ongoing monitoring needs.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide range of industrial applications. For instance, in the oil and gas sector, the BENTLY Nevada is utilized to monitor the health of critical rotating equipment such as pumps and compressors, helping to ensure uninterrupted production and minimize the risk of environmental hazards.

In power generation, this advanced monitoring system is employed to oversee turbines and generators, providing crucial data that enhances reliability and efficiency. The BENTLY Nevada's capabilities extend to manufacturing facilities, where it monitors machinery to optimize production processes and reduce maintenance costs.

Moreover, in the mining industry, the BENTLY Nevada assists in monitoring heavy equipment, ensuring that operations run smoothly and safely. The flexibility and reliability of this system make it an indispensable tool across various sectors, contributing to better asset management and increased operational efficiency.

Comparison with Other Models

When comparing the BENTLY Nevada with other models within the BENTLY lineup, such as the BENTLY 3500/20 or BENTLY 3500/45, it becomes clear that the Nevada stands out with its enhanced features and broader application range.

For example, while the BENTLY 3500/20 focuses primarily on vibration monitoring, the BENTLY Nevada offers a more comprehensive suite of condition monitoring capabilities, including temperature and pressure analysis. Additionally, the BENTLY 3500/45, though effective, lacks the advanced diagnostics and user-friendly interface that are hallmarks of the Nevada model.

The BENTLY 3300 series, while also a strong contender in the field, does not provide the same level of integration and scalability as the BENTLY Nevada, making it less suitable for large-scale operations. The Nevada model’s ability to adapt to various configurations and expand as needed is a significant advantage for businesses looking to future-proof their monitoring systems.

Reference to Related Models

The BENTLY Nevada is part of a robust family of monitoring solutions that includes several related models, each designed to meet specific industrial needs. Here are ten noteworthy models within the BENTLY automation products portfolio:

1. BENTLY 3500/20 125744-02 – Ideal for basic vibration monitoring applications.

2. BENTLY 3500/45 176449-04 – Focuses on machinery protection and monitoring.

3. BENTLY 3500/34 – Offers comprehensive monitoring for various rotating equipment.

4. BENTLY 3500/42M – Designed for advanced machinery protection.

5. BENTLY 3500/50 – Provides extensive data collection capabilities.

6. BENTLY 3500/92 – Known for its enhanced diagnostic features.

7. BENTLY 3300/16-11-01-03-00-00-01 – A versatile option for vibration analysis.

8. BENTLY 3500/77M – Engineered for real-time condition monitoring.

9. BENTLY 3500/15 – A reliable choice for basic monitoring needs.

10. BENTLY 3500/64M – Supports multi-channel monitoring applications.

Conclusion

In a landscape where operational efficiency and equipment reliability are paramount, the BENTLY Nevada emerges as a leader in condition monitoring solutions. Its advanced features, adaptability, and user-friendly interface make it an ideal choice for industries ranging from oil and gas to manufacturing. By choosing the BENTLY Nevada, businesses can harness the power of cutting-edge technology to optimize asset management, reduce operational risks, and enhance overall productivity.

Invest in the future of your operations with the BENTLY Nevada, the premier solution in the realm of BENTLY automation products. Discover how this exceptional system can transform your approach to condition monitoring and help you achieve unparalleled operational success.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada series stands as a hallmark of reliability and precision in the world of industrial automation. Renowned for its advanced technology and robust performance, the BENTLY Nevada is engineered to deliver unparalleled monitoring capabilities for critical machinery in various industries. This product is part of a comprehensive range of BENTLY automation products, designed to enhance operational efficiency and mitigate risks associated with equipment failure.

Key Technical Features

The BENTLY Nevada is equipped with a suite of technical features that set it apart from the competition. At its core, the system boasts a high-performance architecture that supports real-time data acquisition and analysis. This allows for continuous monitoring of machine health, ensuring that potential issues are identified before they escalate into costly downtime.

1. **Advanced Vibration Monitoring**: Utilizing sophisticated algorithms, the BENTLY Nevada provides precise vibration analysis, enabling users to detect anomalies and predict failures in rotating machinery.

2. **Flexible Configuration Options**: The system supports a wide variety of input channels and configurations, accommodating different sensor types and installation requirements. This adaptability makes it suitable for various applications, from turbines and compressors to pumps and motors.

3. **User-Friendly Interface**: The BENTLY Nevada features an intuitive user interface that simplifies navigation and data interpretation. Operators can easily access real-time insights and historical data, making it easier to make informed decisions.

4. **Integrated Diagnostics**: With built-in diagnostic capabilities, the BENTLY Nevada offers detailed reports and alerts, enabling users to address issues proactively and maintain optimal performance levels.

5. **Scalability**: As your operations grow, the BENTLY Nevada can seamlessly integrate with additional sensors and systems, providing a scalable solution for ongoing monitoring needs.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide range of industrial applications. For instance, in the oil and gas sector, the BENTLY Nevada is utilized to monitor the health of critical rotating equipment such as pumps and compressors, helping to ensure uninterrupted production and minimize the risk of environmental hazards.

In power generation, this advanced monitoring system is employed to oversee turbines and generators, providing crucial data that enhances reliability and efficiency. The BENTLY Nevada's capabilities extend to manufacturing facilities, where it monitors machinery to optimize production processes and reduce maintenance costs.

Moreover, in the mining industry, the BENTLY Nevada assists in monitoring heavy equipment, ensuring that operations run smoothly and safely. The flexibility and reliability of this system make it an indispensable tool across various sectors, contributing to better asset management and increased operational efficiency.

Comparison with Other Models

When comparing the BENTLY Nevada with other models within the BENTLY lineup, such as the BENTLY 3500/20 or BENTLY 3500/45, it becomes clear that the Nevada stands out with its enhanced features and broader application range.

For example, while the BENTLY 3500/20 focuses primarily on vibration monitoring, the BENTLY Nevada offers a more comprehensive suite of condition monitoring capabilities, including temperature and pressure analysis. Additionally, the BENTLY 3500/45, though effective, lacks the advanced diagnostics and user-friendly interface that are hallmarks of the Nevada model.

The BENTLY 3300 series, while also a strong contender in the field, does not provide the same level of integration and scalability as the BENTLY Nevada, making it less suitable for large-scale operations. The Nevada model’s ability to adapt to various configurations and expand as needed is a significant advantage for businesses looking to future-proof their monitoring systems.

Reference to Related Models

The BENTLY Nevada is part of a robust family of monitoring solutions that includes several related models, each designed to meet specific industrial needs. Here are ten noteworthy models within the BENTLY automation products portfolio:

1. BENTLY 3500/20 125744-02 – Ideal for basic vibration monitoring applications.

2. BENTLY 3500/45 176449-04 – Focuses on machinery protection and monitoring.

3. BENTLY 3500/34 – Offers comprehensive monitoring for various rotating equipment.

4. BENTLY 3500/42M – Designed for advanced machinery protection.

5. BENTLY 3500/50 – Provides extensive data collection capabilities.

6. BENTLY 3500/92 – Known for its enhanced diagnostic features.

7. BENTLY 3300/16-11-01-03-00-00-01 – A versatile option for vibration analysis.

8. BENTLY 3500/77M – Engineered for real-time condition monitoring.

9. BENTLY 3500/15 – A reliable choice for basic monitoring needs.

10. BENTLY 3500/64M – Supports multi-channel monitoring applications.

Conclusion

In a landscape where operational efficiency and equipment reliability are paramount, the BENTLY Nevada emerges as a leader in condition monitoring solutions. Its advanced features, adaptability, and user-friendly interface make it an ideal choice for industries ranging from oil and gas to manufacturing. By choosing the BENTLY Nevada, businesses can harness the power of cutting-edge technology to optimize asset management, reduce operational risks, and enhance overall productivity.

Invest in the future of your operations with the BENTLY Nevada, the premier solution in the realm of BENTLY automation products. Discover how this exceptional system can transform your approach to condition monitoring and help you achieve unparalleled operational success.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.