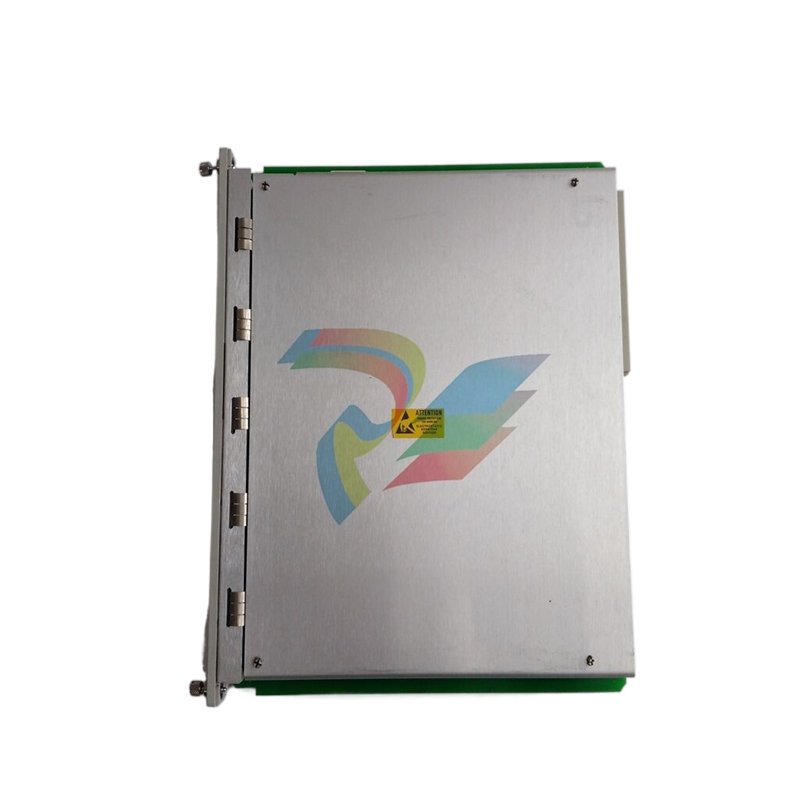

BENTLY Nevada 330104-00-05-05-01-05 Proximity Probes, Advanced Industrial Control Solutions

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring Technology

In the world of industrial automation and condition monitoring, BENTLY Nevada stands as a beacon of innovation and reliability. Designed for the most demanding environments, the BENTLY Nevada series embodies the perfect blend of cutting-edge technology and user-friendly operation. This product is engineered to provide comprehensive monitoring solutions that ensure optimal performance and longevity of your machinery.

Key Technical Features

At the heart of the BENTLY Nevada is its advanced sensor technology, delivering precise vibration and temperature measurements. The system is equipped with high-resolution data acquisition capabilities, allowing for real-time monitoring and analysis of critical machine health parameters. The key technical features include:

1. **Multi-channel Capability**: The BENTLY Nevada supports multiple input channels, enabling simultaneous monitoring of various parameters across different machines.

2. **Robust Data Analysis Tools**: Built-in data analysis software aids in identifying trends and potential failures before they escalate, offering predictive maintenance insights.

3. **Flexible Configuration**: The system allows for customized configurations tailored to specific applications, ensuring maximum efficiency based on operational needs.

4. **User-friendly Interface**: With an intuitive interface, users can easily navigate through the system's functionalities, simplifying the setup and monitoring processes.

5. **Durability and Reliability**: Designed to withstand harsh industrial environments, the BENTLY Nevada is built with rugged materials that ensure longevity and consistent performance in challenging conditions.

6. **Integration with BENTLY Automation Products**: Seamlessly integrates with other BENTLY automation products, allowing for a comprehensive monitoring and control solution across your operations.

Usage Scenarios

The BENTLY Nevada is perfect for various industries, including oil and gas, power generation, manufacturing, and mining. Its versatility makes it suitable for a wide range of applications, such as:

– **Rotating Equipment Monitoring**: Ideal for pumps, compressors, and turbines, the BENTLY Nevada provides continuous monitoring to prevent unexpected downtime due to mechanical failures.

– **Condition-Based Maintenance**: By utilizing real-time data and analytic capabilities, the system supports a shift from time-based maintenance to condition-based maintenance, optimizing resource allocation and reducing costs.

– **Operational Safety Enhancements**: The system’s predictive capabilities help identify potential issues before they lead to catastrophic failures, significantly enhancing workplace safety.

– **Process Optimization**: By ensuring that equipment operates at peak efficiency, the BENTLY Nevada contributes to improved overall operational performance, reducing waste and increasing productivity.

Comparison with Other Models

When comparing the BENTLY Nevada with other models in the BENTLY lineup, such as the BENTLY 3500 series or the BENTLY 3300 series, several distinctions emerge. While the BENTLY 3500 series is renowned for its versatility in monitoring a wide range of applications, the BENTLY Nevada excels in advanced data analysis, providing deeper insights into machine health.

The BENTLY 3300 series, on the other hand, is more focused on basic condition monitoring and vibration analysis, making the BENTLY Nevada a superior choice for industries where predictive maintenance and detailed analytics are essential. Additionally, the BENTLY Nevada’s ability to integrate seamlessly with other BENTLY automation products provides a distinct advantage, ensuring a comprehensive solution for end-users.

Related Models

For those exploring options within the BENTLY brand, here are ten related models worth considering:

1. **BENTLY 3500/20 125744-02**: A versatile monitoring solution for various applications.

2. **BENTLY 3500/45 176449-04**: Designed for advanced vibration monitoring.

3. **BENTLY 3500/40M**: Focused on machinery protection and condition monitoring.

4. **BENTLY 3500/50**: Offers comprehensive monitoring capabilities with enhanced analytics.

5. **BENTLY 3500/34**: Known for its reliability in rotating machinery applications.

6. **BENTLY 330500-00-00**: A robust solution for basic condition monitoring.

7. **BENTLY 3500/22M**: Ideal for monitoring a variety of critical machinery.

8. **BENTLY 3500/25**: Offers detailed monitoring and alarm capabilities.

9. **BENTLY 3500/53**: A specialized model for machine health diagnostics.

10. **BENTLY 3500/40M 176449-01**: Focuses on machinery protection and predictive maintenance.

Conclusion

The BENTLY Nevada represents the future of condition monitoring and predictive maintenance in industrial settings. With its impressive technical features, user-friendly interface, and robust durability, it stands out as the preferred choice for organizations aiming to enhance operational efficiency and equipment reliability. Whether you are looking to integrate it into a new system or upgrade an existing one, the BENTLY Nevada, alongside other BENTLY automation products, ensures you are well-equipped to face the challenges of modern industrial operations. Invest in the BENTLY Nevada today and experience unparalleled monitoring solutions that keep your machinery running smoothly and your operations thriving.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation and condition monitoring, BENTLY Nevada stands as a beacon of innovation and reliability. Designed for the most demanding environments, the BENTLY Nevada series embodies the perfect blend of cutting-edge technology and user-friendly operation. This product is engineered to provide comprehensive monitoring solutions that ensure optimal performance and longevity of your machinery.

Key Technical Features

At the heart of the BENTLY Nevada is its advanced sensor technology, delivering precise vibration and temperature measurements. The system is equipped with high-resolution data acquisition capabilities, allowing for real-time monitoring and analysis of critical machine health parameters. The key technical features include:

1. **Multi-channel Capability**: The BENTLY Nevada supports multiple input channels, enabling simultaneous monitoring of various parameters across different machines.

2. **Robust Data Analysis Tools**: Built-in data analysis software aids in identifying trends and potential failures before they escalate, offering predictive maintenance insights.

3. **Flexible Configuration**: The system allows for customized configurations tailored to specific applications, ensuring maximum efficiency based on operational needs.

4. **User-friendly Interface**: With an intuitive interface, users can easily navigate through the system's functionalities, simplifying the setup and monitoring processes.

5. **Durability and Reliability**: Designed to withstand harsh industrial environments, the BENTLY Nevada is built with rugged materials that ensure longevity and consistent performance in challenging conditions.

6. **Integration with BENTLY Automation Products**: Seamlessly integrates with other BENTLY automation products, allowing for a comprehensive monitoring and control solution across your operations.

Usage Scenarios

The BENTLY Nevada is perfect for various industries, including oil and gas, power generation, manufacturing, and mining. Its versatility makes it suitable for a wide range of applications, such as:

– **Rotating Equipment Monitoring**: Ideal for pumps, compressors, and turbines, the BENTLY Nevada provides continuous monitoring to prevent unexpected downtime due to mechanical failures.

– **Condition-Based Maintenance**: By utilizing real-time data and analytic capabilities, the system supports a shift from time-based maintenance to condition-based maintenance, optimizing resource allocation and reducing costs.

– **Operational Safety Enhancements**: The system’s predictive capabilities help identify potential issues before they lead to catastrophic failures, significantly enhancing workplace safety.

– **Process Optimization**: By ensuring that equipment operates at peak efficiency, the BENTLY Nevada contributes to improved overall operational performance, reducing waste and increasing productivity.

Comparison with Other Models

When comparing the BENTLY Nevada with other models in the BENTLY lineup, such as the BENTLY 3500 series or the BENTLY 3300 series, several distinctions emerge. While the BENTLY 3500 series is renowned for its versatility in monitoring a wide range of applications, the BENTLY Nevada excels in advanced data analysis, providing deeper insights into machine health.

The BENTLY 3300 series, on the other hand, is more focused on basic condition monitoring and vibration analysis, making the BENTLY Nevada a superior choice for industries where predictive maintenance and detailed analytics are essential. Additionally, the BENTLY Nevada’s ability to integrate seamlessly with other BENTLY automation products provides a distinct advantage, ensuring a comprehensive solution for end-users.

Related Models

For those exploring options within the BENTLY brand, here are ten related models worth considering:

1. **BENTLY 3500/20 125744-02**: A versatile monitoring solution for various applications.

2. **BENTLY 3500/45 176449-04**: Designed for advanced vibration monitoring.

3. **BENTLY 3500/40M**: Focused on machinery protection and condition monitoring.

4. **BENTLY 3500/50**: Offers comprehensive monitoring capabilities with enhanced analytics.

5. **BENTLY 3500/34**: Known for its reliability in rotating machinery applications.

6. **BENTLY 330500-00-00**: A robust solution for basic condition monitoring.

7. **BENTLY 3500/22M**: Ideal for monitoring a variety of critical machinery.

8. **BENTLY 3500/25**: Offers detailed monitoring and alarm capabilities.

9. **BENTLY 3500/53**: A specialized model for machine health diagnostics.

10. **BENTLY 3500/40M 176449-01**: Focuses on machinery protection and predictive maintenance.

Conclusion

The BENTLY Nevada represents the future of condition monitoring and predictive maintenance in industrial settings. With its impressive technical features, user-friendly interface, and robust durability, it stands out as the preferred choice for organizations aiming to enhance operational efficiency and equipment reliability. Whether you are looking to integrate it into a new system or upgrade an existing one, the BENTLY Nevada, alongside other BENTLY automation products, ensures you are well-equipped to face the challenges of modern industrial operations. Invest in the BENTLY Nevada today and experience unparalleled monitoring solutions that keep your machinery running smoothly and your operations thriving.

The above parameters are for reference only. Please contact our technical team for precise selection.

.jpg)

There are no reviews yet.