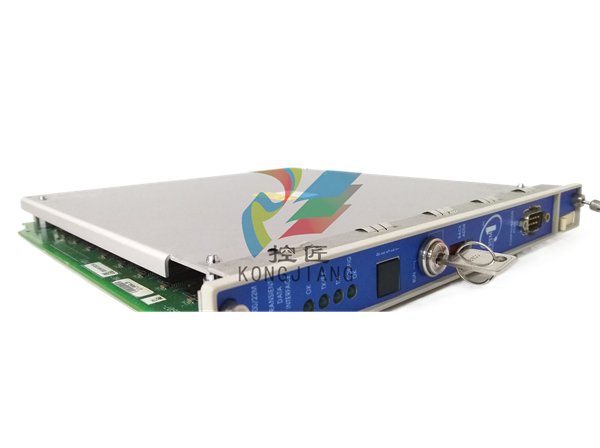

BENTLY Nevada 330130-085-00-CN Precision Control Solutions for Industrial Automation

Introducing the BENTLY Nevada 330130-085-00-CN: the pinnacle of precision in condition monitoring and vibration analysis from a renowned leader in industrial automation. This advanced model is engineered to enhance the reliability and efficiency of your machinery, ensuring optimal performance across various operational conditions.

**Key Technical Features**

The BENTLY Nevada 330130-085-00-CN stands out with its cutting-edge technology and robust design. It features a high-accuracy measurement system that allows for real-time monitoring of vibration levels. This model supports advanced signal processing algorithms, enabling it to detect even the slightest changes in machinery behavior. The unit is equipped with a wide frequency range, making it suitable for a diverse array of applications, from large turbines to smaller pumps.

One of the key highlights of the BENTLY Nevada 330130-085-00-CN is its support for multi-channel configurations, allowing users to monitor multiple points on a machine simultaneously. This capability is crucial for comprehensive analysis and troubleshooting. Furthermore, the model is designed for seamless integration with BENTLY automation products, providing a cohesive ecosystem for data collection and monitoring.

Another notable feature is its user-friendly interface, which simplifies setup and configuration. The device offers extensive diagnostics and reporting capabilities, ensuring that operators can quickly identify potential issues before they escalate into costly failures. Its rugged construction and high environmental rating make it suitable for harsh industrial environments, ensuring longevity and reliability.

**Usage Scenarios**

The BENTLY Nevada 330130-085-00-CN is versatile, making it ideal for various industries such as oil and gas, power generation, and manufacturing. In the oil and gas sector, for instance, it can be employed to monitor the health of critical equipment like compressors and turbines, where even minor faults can lead to significant downtime or safety hazards.

In power generation, the model can be used to ensure the optimal performance of generators and turbines, helping to maintain efficiency and reduce maintenance costs. Manufacturing facilities benefit from its application in monitoring rotating machinery, where early detection of wear or misalignment can prevent catastrophic failures and enhance overall productivity.

Additionally, the BENTLY Nevada 330130-085-00-CN is perfect for continuous monitoring applications, allowing businesses to implement predictive maintenance strategies that maximize uptime and reduce operational costs. Its ability to interface with various BENTLY automation products means that users can create a comprehensive monitoring system tailored to their specific needs.

**Comparison with Other Models**

When compared to other models within the BENTLY Nevada range, such as the BENTLY 3500 series, the 330130-085-00-CN excels in its multi-channel capabilities and advanced signal processing. While models like the BENTLY 3500/20 and BENTLY 3500/40M provide excellent monitoring solutions, the 330130-085-00-CN offers enhanced features for environments where comprehensive vibration analysis is critical.

For example, the BENTLY 3500/45 is designed for specific applications and may not provide the same level of flexibility as the 330130-085-00-CN. Similarly, the BENTLY 3500/92 is more specialized for certain types of machinery, whereas the 330130-085-00-CN’s versatility makes it a suitable choice for a wider range of industrial applications.

Another notable mention is the BENTLY 330500-00-00, which is a great option for basic vibration monitoring; however, it lacks the advanced features and user-friendly interface that the 330130-085-00-CN boasts. In contrast, the 330130-085-00-CN is designed for professionals who require a high level of accuracy and reliability in their monitoring solutions.

**Related Models**

To give you a broader perspective, here are ten related models from the BENTLY range that complement the features of the BENTLY Nevada 330130-085-00-CN:

1. BENTLY 3500/20 125744-02

2. BENTLY 3500/40M 176449-01

3. BENTLY 3500/45 176449-04

4. BENTLY 3500/34

5. BENTLY 3500/50

6. BENTLY 3500/92

7. BENTLY 330500-00-00

8. BENTLY 3500/53 133388-01

9. BENTLY 330130-040-00-00

10. BENTLY 3500/25

These models offer various functionalities that cater to specific monitoring needs, allowing you to choose the right equipment for your operational requirements.

**Conclusion**

The BENTLY Nevada 330130-085-00-CN is a powerful tool for industries that depend on the reliability of their machinery. Its advanced features, wide application range, and user-friendly design make it an indispensable addition to any condition monitoring program. By integrating this model with other BENTLY automation products, businesses can establish a comprehensive and effective monitoring system that enhances operational efficiency and minimizes downtime. Choose the BENTLY Nevada 330130-085-00-CN for unparalleled performance in vibration analysis and condition monitoring.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The BENTLY Nevada 330130-085-00-CN stands out with its cutting-edge technology and robust design. It features a high-accuracy measurement system that allows for real-time monitoring of vibration levels. This model supports advanced signal processing algorithms, enabling it to detect even the slightest changes in machinery behavior. The unit is equipped with a wide frequency range, making it suitable for a diverse array of applications, from large turbines to smaller pumps.

One of the key highlights of the BENTLY Nevada 330130-085-00-CN is its support for multi-channel configurations, allowing users to monitor multiple points on a machine simultaneously. This capability is crucial for comprehensive analysis and troubleshooting. Furthermore, the model is designed for seamless integration with BENTLY automation products, providing a cohesive ecosystem for data collection and monitoring.

Another notable feature is its user-friendly interface, which simplifies setup and configuration. The device offers extensive diagnostics and reporting capabilities, ensuring that operators can quickly identify potential issues before they escalate into costly failures. Its rugged construction and high environmental rating make it suitable for harsh industrial environments, ensuring longevity and reliability.

**Usage Scenarios**

The BENTLY Nevada 330130-085-00-CN is versatile, making it ideal for various industries such as oil and gas, power generation, and manufacturing. In the oil and gas sector, for instance, it can be employed to monitor the health of critical equipment like compressors and turbines, where even minor faults can lead to significant downtime or safety hazards.

In power generation, the model can be used to ensure the optimal performance of generators and turbines, helping to maintain efficiency and reduce maintenance costs. Manufacturing facilities benefit from its application in monitoring rotating machinery, where early detection of wear or misalignment can prevent catastrophic failures and enhance overall productivity.

Additionally, the BENTLY Nevada 330130-085-00-CN is perfect for continuous monitoring applications, allowing businesses to implement predictive maintenance strategies that maximize uptime and reduce operational costs. Its ability to interface with various BENTLY automation products means that users can create a comprehensive monitoring system tailored to their specific needs.

**Comparison with Other Models**

When compared to other models within the BENTLY Nevada range, such as the BENTLY 3500 series, the 330130-085-00-CN excels in its multi-channel capabilities and advanced signal processing. While models like the BENTLY 3500/20 and BENTLY 3500/40M provide excellent monitoring solutions, the 330130-085-00-CN offers enhanced features for environments where comprehensive vibration analysis is critical.

For example, the BENTLY 3500/45 is designed for specific applications and may not provide the same level of flexibility as the 330130-085-00-CN. Similarly, the BENTLY 3500/92 is more specialized for certain types of machinery, whereas the 330130-085-00-CN’s versatility makes it a suitable choice for a wider range of industrial applications.

Another notable mention is the BENTLY 330500-00-00, which is a great option for basic vibration monitoring; however, it lacks the advanced features and user-friendly interface that the 330130-085-00-CN boasts. In contrast, the 330130-085-00-CN is designed for professionals who require a high level of accuracy and reliability in their monitoring solutions.

**Related Models**

To give you a broader perspective, here are ten related models from the BENTLY range that complement the features of the BENTLY Nevada 330130-085-00-CN:

1. BENTLY 3500/20 125744-02

2. BENTLY 3500/40M 176449-01

3. BENTLY 3500/45 176449-04

4. BENTLY 3500/34

5. BENTLY 3500/50

6. BENTLY 3500/92

7. BENTLY 330500-00-00

8. BENTLY 3500/53 133388-01

9. BENTLY 330130-040-00-00

10. BENTLY 3500/25

These models offer various functionalities that cater to specific monitoring needs, allowing you to choose the right equipment for your operational requirements.

**Conclusion**

The BENTLY Nevada 330130-085-00-CN is a powerful tool for industries that depend on the reliability of their machinery. Its advanced features, wide application range, and user-friendly design make it an indispensable addition to any condition monitoring program. By integrating this model with other BENTLY automation products, businesses can establish a comprehensive and effective monitoring system that enhances operational efficiency and minimizes downtime. Choose the BENTLY Nevada 330130-085-00-CN for unparalleled performance in vibration analysis and condition monitoring.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.