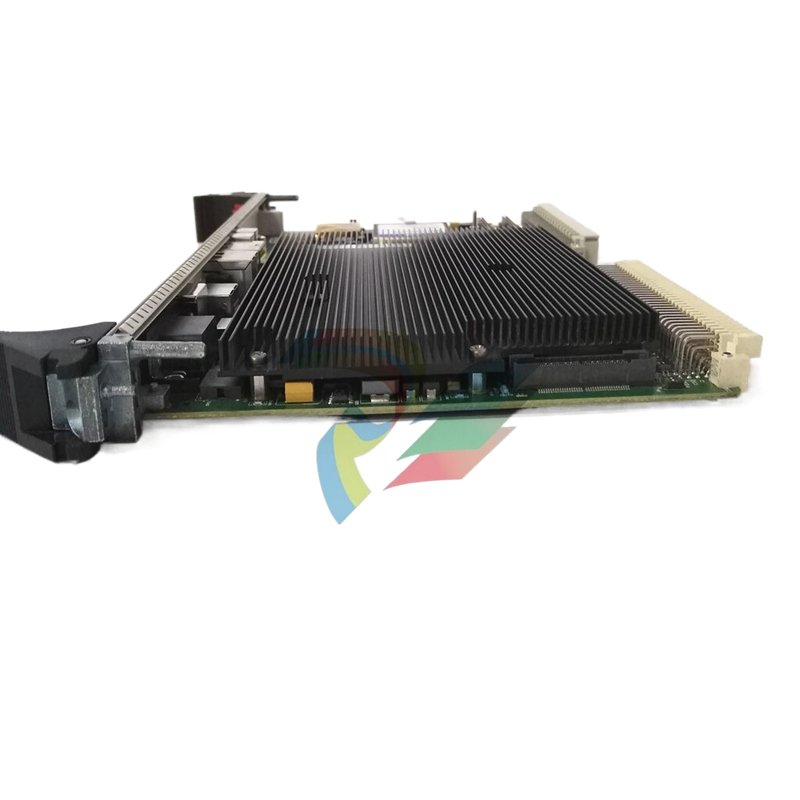

GE Electric DS3800HCMC Gas Turbine Daughter Board For Enhanced Control & Efficiency

Introducing the GE Electric, a pinnacle of innovation and reliability in the world of automation products. This model exemplifies GE's commitment to delivering cutting-edge technology designed to meet the diverse needs of industrial operations. With its advanced features and robust performance, the GE Electric stands out as a vital component for manufacturers and engineers seeking to enhance their automation processes.

Key Technical Features

At the heart of the GE Electric is a powerful processing unit that guarantees swift and efficient control of complex operations. It boasts a high-performance CPU, optimized for speed and responsiveness, ensuring that your automation tasks are executed seamlessly. The device offers extensive I/O capabilities, accommodating a wide array of input and output modules, which allows for greater flexibility in application design.

The GE Electric is equipped with advanced communication interfaces, including Ethernet and serial connections, enabling real-time data exchange with other devices and systems. This connectivity is essential for industries that rely on rapid response times and synchronized operations. Additionally, the model supports various protocols, ensuring compatibility with existing systems and facilitating integration into your current automation infrastructure.

A standout feature is its built-in diagnostics and monitoring tools, which provide real-time insights into system performance. These tools help to identify potential issues before they escalate, minimizing downtime and enhancing operational efficiency. The GE Electric is also designed with user-friendly software, allowing for easy programming and configuration, making it accessible for both seasoned professionals and those new to automation technology.

Usage Scenarios

The versatility of the GE Electric makes it ideal for a variety of applications across multiple industries. In manufacturing, it can streamline production processes by coordinating machinery and ensuring that all components work in harmony. This is particularly beneficial in assembly lines where precision and timing are critical.

In the energy sector, the GE Electric can monitor and control power generation and distribution systems. Its ability to handle high-load applications makes it suitable for managing renewable energy sources, such as wind and solar farms, where efficient energy management is essential.

The model is also well-suited for water treatment facilities, where it can automate processes such as pumping, filtration, and chemical dosing. By utilizing the GE Electric, operators can enhance the accuracy and reliability of their water management systems while reducing labor costs.

Comparison with Other Models

When comparing the GE Electric to other models within the GE family, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, it becomes evident that the GE Electric offers superior processing capabilities and flexibility. While the IS200TBCIH1BBC is known for its robust performance in specific applications, the GE Electric excels in versatility, making it a better choice for multi-faceted operations.

In contrast to the GE CT7P70500470CW24, which is tailored for specialized control applications, the GE Electric provides broader compatibility with various automation products. This makes it an ideal choice for organizations looking to future-proof their operations with a device that can adapt to evolving technology and industry demands.

For users who may consider the GE IS215UCVEH2AB or GE IC697MDL250, the GE Electric offers enhanced communication features, allowing for easier integration with modern industrial networks. This capability ensures that businesses can achieve a higher level of automation and real-time data management compared to other models.

Reference to Related Models

The GE Electric is part of a comprehensive lineup of GE automation products that includes models such as the GE IC660ELB912G, known for its reliability in harsh environments, and the GE IS200TPROH1BCB, which is widely used for process control. Other related models include the GE DS200CTBAG1ADD, a favorite for its diagnostics features, and the GE IS230SNIDH1A, which offers advanced safety functions.

For those interested in communication-focused solutions, the GE PRG-MODEM provides essential connectivity options, while the GE IC670MDL740J is recognized for its extensive I/O capabilities. The GE IC693CPU374 serves as an excellent option for users needing a balance of performance and cost-effectiveness, while the GE IC698ACC701 stands out for its high-speed processing abilities.

In addition, models like the GE 531X307LTBAJG1 and GE DS200SDCCG5AHD are vital for users requiring specific industry certifications and customization options. Each model within the GE automation product range complements the GE Electric, providing businesses with numerous choices to tailor their automation solutions according to their unique requirements.

Conclusion

The GE Electric is a powerful and adaptable solution tailored for modern industrial automation needs. With its advanced features, versatility in application, and a solid foundation within the GE family of automation products, it is designed to enhance operational efficiency and reliability. Whether you are in manufacturing, energy, or water treatment, the GE Electric is equipped to handle your automation challenges with ease. By choosing the GE Electric, you are investing in a future-proof solution that stands ready to evolve alongside your business. Experience the difference with GE Electric and elevate your automation processes today.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

At the heart of the GE Electric is a powerful processing unit that guarantees swift and efficient control of complex operations. It boasts a high-performance CPU, optimized for speed and responsiveness, ensuring that your automation tasks are executed seamlessly. The device offers extensive I/O capabilities, accommodating a wide array of input and output modules, which allows for greater flexibility in application design.

The GE Electric is equipped with advanced communication interfaces, including Ethernet and serial connections, enabling real-time data exchange with other devices and systems. This connectivity is essential for industries that rely on rapid response times and synchronized operations. Additionally, the model supports various protocols, ensuring compatibility with existing systems and facilitating integration into your current automation infrastructure.

A standout feature is its built-in diagnostics and monitoring tools, which provide real-time insights into system performance. These tools help to identify potential issues before they escalate, minimizing downtime and enhancing operational efficiency. The GE Electric is also designed with user-friendly software, allowing for easy programming and configuration, making it accessible for both seasoned professionals and those new to automation technology.

Usage Scenarios

The versatility of the GE Electric makes it ideal for a variety of applications across multiple industries. In manufacturing, it can streamline production processes by coordinating machinery and ensuring that all components work in harmony. This is particularly beneficial in assembly lines where precision and timing are critical.

In the energy sector, the GE Electric can monitor and control power generation and distribution systems. Its ability to handle high-load applications makes it suitable for managing renewable energy sources, such as wind and solar farms, where efficient energy management is essential.

The model is also well-suited for water treatment facilities, where it can automate processes such as pumping, filtration, and chemical dosing. By utilizing the GE Electric, operators can enhance the accuracy and reliability of their water management systems while reducing labor costs.

Comparison with Other Models

When comparing the GE Electric to other models within the GE family, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, it becomes evident that the GE Electric offers superior processing capabilities and flexibility. While the IS200TBCIH1BBC is known for its robust performance in specific applications, the GE Electric excels in versatility, making it a better choice for multi-faceted operations.

In contrast to the GE CT7P70500470CW24, which is tailored for specialized control applications, the GE Electric provides broader compatibility with various automation products. This makes it an ideal choice for organizations looking to future-proof their operations with a device that can adapt to evolving technology and industry demands.

For users who may consider the GE IS215UCVEH2AB or GE IC697MDL250, the GE Electric offers enhanced communication features, allowing for easier integration with modern industrial networks. This capability ensures that businesses can achieve a higher level of automation and real-time data management compared to other models.

Reference to Related Models

The GE Electric is part of a comprehensive lineup of GE automation products that includes models such as the GE IC660ELB912G, known for its reliability in harsh environments, and the GE IS200TPROH1BCB, which is widely used for process control. Other related models include the GE DS200CTBAG1ADD, a favorite for its diagnostics features, and the GE IS230SNIDH1A, which offers advanced safety functions.

For those interested in communication-focused solutions, the GE PRG-MODEM provides essential connectivity options, while the GE IC670MDL740J is recognized for its extensive I/O capabilities. The GE IC693CPU374 serves as an excellent option for users needing a balance of performance and cost-effectiveness, while the GE IC698ACC701 stands out for its high-speed processing abilities.

In addition, models like the GE 531X307LTBAJG1 and GE DS200SDCCG5AHD are vital for users requiring specific industry certifications and customization options. Each model within the GE automation product range complements the GE Electric, providing businesses with numerous choices to tailor their automation solutions according to their unique requirements.

Conclusion

The GE Electric is a powerful and adaptable solution tailored for modern industrial automation needs. With its advanced features, versatility in application, and a solid foundation within the GE family of automation products, it is designed to enhance operational efficiency and reliability. Whether you are in manufacturing, energy, or water treatment, the GE Electric is equipped to handle your automation challenges with ease. By choosing the GE Electric, you are investing in a future-proof solution that stands ready to evolve alongside your business. Experience the difference with GE Electric and elevate your automation processes today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.