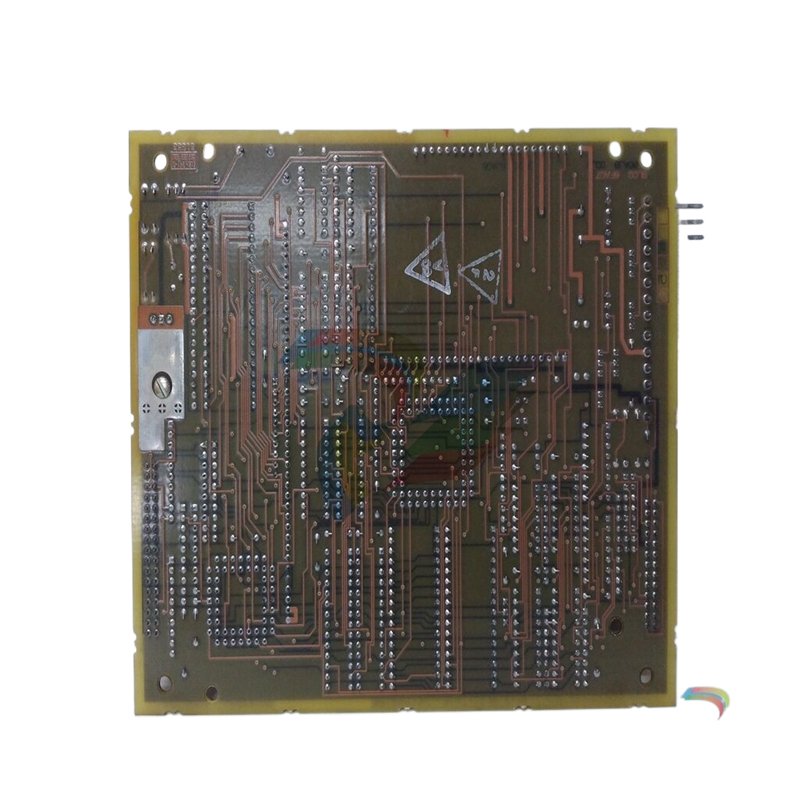

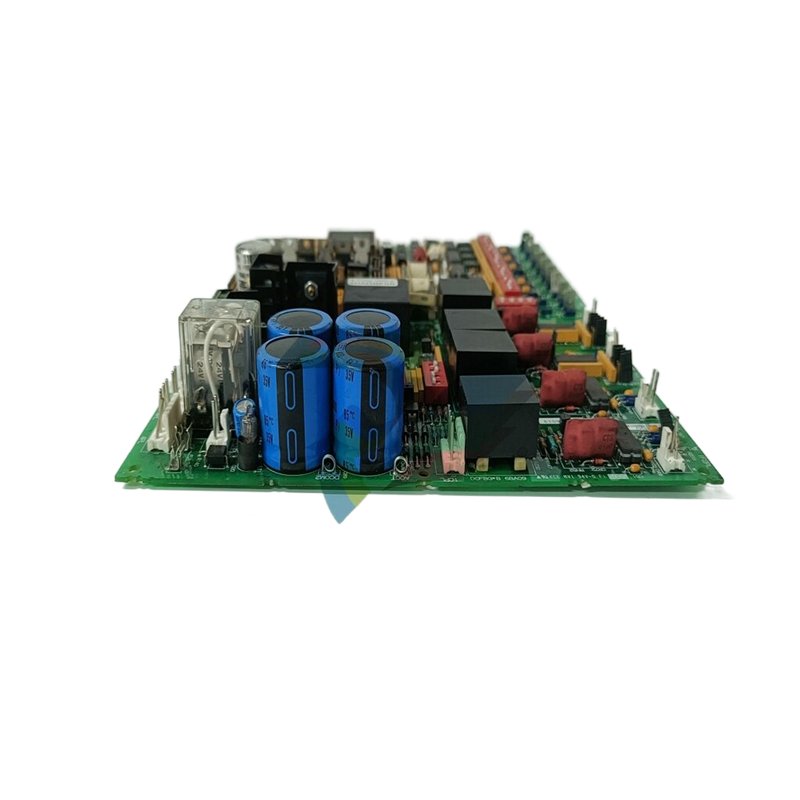

GE Electric IS200STAIH2A Analog I/O Terminal Board Precision Control Module

Introducing the GE Electric: A Comprehensive Solution for Modern Automation Needs

In today's fast-paced industrial landscape, the need for reliable and efficient automation products is paramount. The GE Electric model stands out as a leading solution, offering a blend of advanced technology and user-friendly features tailored for a variety of applications. This description delves into the key technical features of the GE Electric, explores its usage scenarios, compares it with other models, and highlights related products in the GE automation portfolio.

Key Technical Features

The GE Electric is engineered with cutting-edge technology to ensure optimal performance in demanding environments. Among its standout features are:

1. **Robust Processing Power**: The GE Electric is equipped with a powerful CPU that enhances processing speed, allowing for quick decision-making in automation tasks. This ensures real-time monitoring and control, essential for industries that require immediate data processing.

2. **Modular Design**: The model supports a modular architecture, enabling users to customize their configuration based on specific needs. This flexibility allows for easy upgrades and maintenance, ensuring longevity and scalability.

3. **Advanced Communication Protocols**: The GE Electric supports various communication protocols, including Ethernet and serial communication, facilitating seamless integration with other GE automation products and third-party devices. This feature is crucial for creating a cohesive automation environment.

4. **High-Performance I/O Modules**: With a range of input/output modules available, the GE Electric allows for extensive connectivity options, accommodating everything from simple sensors to complex machinery. This versatility makes it suitable for diverse industrial applications.

5. **User-Friendly Interface**: The intuitive interface provides users with easy access to system information and control options, minimizing training time and enhancing operational efficiency.

6. **Robust Safety Features**: Safety is a top priority in industrial automation. The GE Electric incorporates advanced safety features to protect both personnel and equipment from potential hazards, ensuring compliance with industry standards.

Usage Scenarios

The GE Electric is designed for a myriad of applications, making it a versatile choice for numerous industries. Some common usage scenarios include:

1. **Manufacturing Automation**: In manufacturing plants, the GE Electric can control assembly lines, monitor machinery performance, and optimize production processes, resulting in improved efficiency and reduced downtime.

2. **Energy Management**: The model is well-suited for energy management applications, allowing for the monitoring and control of energy consumption in facilities, contributing to sustainability efforts and cost savings.

3. **Process Control**: Industries such as oil and gas, pharmaceuticals, and chemicals leverage the GE Electric for precise process control, ensuring quality and consistency in production.

4. **Transportation Systems**: The GE Electric can be integrated into transportation systems for traffic management, ensuring smooth operations and enhancing safety across roadways and railways.

5. **Building Automation**: In smart buildings, the GE Electric facilitates systems integration for lighting, HVAC, and security, delivering a comprehensive solution for building management.

Comparison with Other Models

When comparing the GE Electric with other models from the GE automation products lineup, several distinctions become apparent. For instance, while models like the GE IS200TBCIH1BBC and GE IS220PPROS1B are tailored for specific industrial applications, the GE Electric offers a more general-purpose platform with greater adaptability.

The GE CT7P70500470CW24, known for its compact design, is ideal for space-constrained environments but may lack the extensive I/O options available in the GE Electric. Conversely, models like the GE IS215UCVEH2AB and GE IS230SNIDH1A focus on specialized control tasks, whereas the GE Electric provides a broader scope for diverse automation needs.

In terms of processing capabilities, the GE IC697MDL250 and GE 369-HI-0-M-0-0-0 excel in specific control applications, but the GE Electric's robust CPU ensures superior performance across multiple functions. This makes it a preferred choice for businesses seeking a versatile and powerful automation solution.

Related Models

The GE Electric is part of a comprehensive suite of GE automation products designed to enhance industrial efficiency. Here are ten related models that complement the GE Electric:

1. **GE IS200TBCIH1BBC** – A specialized control system for critical applications.

2. **GE IS220PPROS1B** – Known for its precision in data processing tasks.

3. **GE CT7P70500470CW24** – A compact model ideal for limited spaces.

4. **GE EVMECNTM13** – Targeted for advanced motion control applications.

5. **GE IC697MDL250** – Offers reliable I/O capabilities for various industrial needs.

6. **GE PRG-MODEM** – Facilitates communication for remote access and monitoring.

7. **GE IS215UCVEH2AB** – Focuses on user-friendly interfaces for enhanced control.

8. **GE IC660EBD020** – Known for its robust performance in demanding environments.

9. **GE IS200DSPXH1DBC** – A digital signal processor for specialized automation tasks.

10. **GE DS200CTBAG1ADD** – A versatile controller designed for a wide range of industrial applications.

Conclusion

The GE Electric is a premier choice for businesses looking to enhance their automation systems. With its powerful processing capabilities, modular design, and extensive communication options, it meets the diverse needs of modern industries. Whether you’re in manufacturing, energy management, or building automation, the GE Electric, combined with its related models, provides a comprehensive solution that drives efficiency, safety, and performance. By choosing the GE Electric, you are investing in a future-ready automation product that adapts to your evolving industrial landscape.

The above parameters are for reference only. Please contact our technical team for precise selection.

In today's fast-paced industrial landscape, the need for reliable and efficient automation products is paramount. The GE Electric model stands out as a leading solution, offering a blend of advanced technology and user-friendly features tailored for a variety of applications. This description delves into the key technical features of the GE Electric, explores its usage scenarios, compares it with other models, and highlights related products in the GE automation portfolio.

Key Technical Features

The GE Electric is engineered with cutting-edge technology to ensure optimal performance in demanding environments. Among its standout features are:

1. **Robust Processing Power**: The GE Electric is equipped with a powerful CPU that enhances processing speed, allowing for quick decision-making in automation tasks. This ensures real-time monitoring and control, essential for industries that require immediate data processing.

2. **Modular Design**: The model supports a modular architecture, enabling users to customize their configuration based on specific needs. This flexibility allows for easy upgrades and maintenance, ensuring longevity and scalability.

3. **Advanced Communication Protocols**: The GE Electric supports various communication protocols, including Ethernet and serial communication, facilitating seamless integration with other GE automation products and third-party devices. This feature is crucial for creating a cohesive automation environment.

4. **High-Performance I/O Modules**: With a range of input/output modules available, the GE Electric allows for extensive connectivity options, accommodating everything from simple sensors to complex machinery. This versatility makes it suitable for diverse industrial applications.

5. **User-Friendly Interface**: The intuitive interface provides users with easy access to system information and control options, minimizing training time and enhancing operational efficiency.

6. **Robust Safety Features**: Safety is a top priority in industrial automation. The GE Electric incorporates advanced safety features to protect both personnel and equipment from potential hazards, ensuring compliance with industry standards.

Usage Scenarios

The GE Electric is designed for a myriad of applications, making it a versatile choice for numerous industries. Some common usage scenarios include:

1. **Manufacturing Automation**: In manufacturing plants, the GE Electric can control assembly lines, monitor machinery performance, and optimize production processes, resulting in improved efficiency and reduced downtime.

2. **Energy Management**: The model is well-suited for energy management applications, allowing for the monitoring and control of energy consumption in facilities, contributing to sustainability efforts and cost savings.

3. **Process Control**: Industries such as oil and gas, pharmaceuticals, and chemicals leverage the GE Electric for precise process control, ensuring quality and consistency in production.

4. **Transportation Systems**: The GE Electric can be integrated into transportation systems for traffic management, ensuring smooth operations and enhancing safety across roadways and railways.

5. **Building Automation**: In smart buildings, the GE Electric facilitates systems integration for lighting, HVAC, and security, delivering a comprehensive solution for building management.

Comparison with Other Models

When comparing the GE Electric with other models from the GE automation products lineup, several distinctions become apparent. For instance, while models like the GE IS200TBCIH1BBC and GE IS220PPROS1B are tailored for specific industrial applications, the GE Electric offers a more general-purpose platform with greater adaptability.

The GE CT7P70500470CW24, known for its compact design, is ideal for space-constrained environments but may lack the extensive I/O options available in the GE Electric. Conversely, models like the GE IS215UCVEH2AB and GE IS230SNIDH1A focus on specialized control tasks, whereas the GE Electric provides a broader scope for diverse automation needs.

In terms of processing capabilities, the GE IC697MDL250 and GE 369-HI-0-M-0-0-0 excel in specific control applications, but the GE Electric's robust CPU ensures superior performance across multiple functions. This makes it a preferred choice for businesses seeking a versatile and powerful automation solution.

Related Models

The GE Electric is part of a comprehensive suite of GE automation products designed to enhance industrial efficiency. Here are ten related models that complement the GE Electric:

1. **GE IS200TBCIH1BBC** – A specialized control system for critical applications.

2. **GE IS220PPROS1B** – Known for its precision in data processing tasks.

3. **GE CT7P70500470CW24** – A compact model ideal for limited spaces.

4. **GE EVMECNTM13** – Targeted for advanced motion control applications.

5. **GE IC697MDL250** – Offers reliable I/O capabilities for various industrial needs.

6. **GE PRG-MODEM** – Facilitates communication for remote access and monitoring.

7. **GE IS215UCVEH2AB** – Focuses on user-friendly interfaces for enhanced control.

8. **GE IC660EBD020** – Known for its robust performance in demanding environments.

9. **GE IS200DSPXH1DBC** – A digital signal processor for specialized automation tasks.

10. **GE DS200CTBAG1ADD** – A versatile controller designed for a wide range of industrial applications.

Conclusion

The GE Electric is a premier choice for businesses looking to enhance their automation systems. With its powerful processing capabilities, modular design, and extensive communication options, it meets the diverse needs of modern industries. Whether you’re in manufacturing, energy management, or building automation, the GE Electric, combined with its related models, provides a comprehensive solution that drives efficiency, safety, and performance. By choosing the GE Electric, you are investing in a future-ready automation product that adapts to your evolving industrial landscape.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.