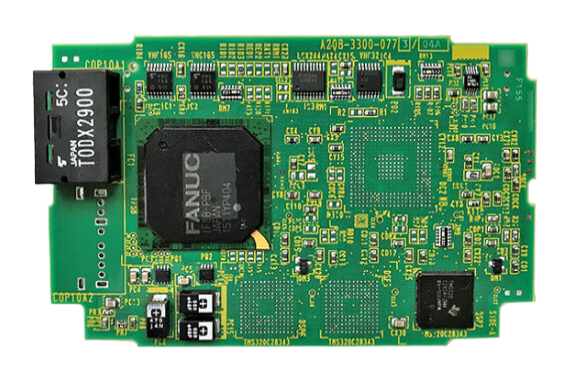

GE Fanuc IC200MDL650D Process Module Industrial Control Solution

Introducing the GE Fanuc: A Pinnacle of Industrial Automation Technology

In the ever-evolving world of industrial automation, GE Fanuc stands out as a trusted name synonymous with innovation, reliability, and performance. The GE Fanuc model is engineered to meet the rigorous demands of modern manufacturing and process control, ensuring that your operations run smoothly and efficiently. Below, we delve into the key technical features of the GE Fanuc, explore various usage scenarios, compare it with other models, and highlight related products within the extensive GE automation products lineup.

Key Technical Features

The GE Fanuc model brings together cutting-edge technology and user-centric design to deliver exceptional performance. Here are some of its key technical features:

1. **High Performance Processing**: Equipped with advanced processors, the GE Fanuc model ensures rapid data processing and response times, crucial for real-time applications in industrial settings.

2. **Robust Connectivity Options**: This model supports multiple communication protocols, making it compatible with a wide range of devices and systems. Its Ethernet and serial communication capabilities allow seamless integration into existing networks.

3. **Scalability**: Designed to grow with your business, the GE Fanuc model offers scalable solutions that can be easily expanded to accommodate increased production demands or additional functionalities.

4. **Versatile I/O Configuration**: With a variety of input and output modules, this model can be tailored to meet specific application requirements, ensuring flexibility in both configuration and deployment.

5. **User-Friendly Interface**: The GE Fanuc features an intuitive interface that simplifies programming and monitoring, empowering operators to efficiently manage processes and quickly respond to any issues that arise.

6. **Enhanced Reliability**: Built with industrial-grade components, the GE Fanuc model is designed to withstand harsh operating conditions, ensuring minimal downtime and maximum productivity.

Usage Scenarios

The GE Fanuc model is ideal for a variety of applications across different industries. Here are some typical usage scenarios:

1. **Manufacturing Automation**: In factories, the GE Fanuc can control robotic arms, conveyor systems, and assembly lines, facilitating streamlined production processes and enhancing operational efficiency.

2. **Process Control**: In chemical and petrochemical industries, the GE Fanuc excels at monitoring and controlling complex processes, managing variables such as temperature, pressure, and flow rates to ensure product quality and safety.

3. **Energy Management**: The GE Fanuc is utilized in energy management systems, allowing for real-time monitoring of energy consumption and automating controls to optimize energy use and reduce costs.

4. **Water Treatment**: In municipal water treatment facilities, this model aids in managing water purification processes, ensuring compliance with environmental regulations while maintaining operational efficiency.

5. **Building Automation**: The GE Fanuc is integrated into building management systems, controlling HVAC systems, lighting, and security, thereby enhancing comfort while maximizing energy savings.

Comparison with Other Models

When compared to other models within the GE automation products lineup, the GE Fanuc distinguishes itself through its balance of performance and versatility. For instance:

– **GE SR750**: While the SR750 is known for its superior processing speed, the GE Fanuc offers a broader range of I/O options, making it more adaptable for diverse applications.

– **GE IS200DSPXH2DBD**: The IS200DSPXH2DBD model specializes in digital signal processing, but the GE Fanuc provides a more comprehensive set of features for general automation tasks.

– **GE IC695CPE310-ABAH**: Although the IC695CPE310-ABAH is a robust PLC with excellent communication capabilities, the GE Fanuc’s user-friendly interface often makes it a preferred choice for operators seeking ease of use.

– **GE IS200JPDMG1ADC**: This model focuses on specific control tasks, while the GE Fanuc is more versatile, capable of handling a wider array of control and monitoring functions.

Overall, the GE Fanuc is a well-rounded solution that can effectively address the needs of various industries while competing favorably against other models.

Related Models

To further illustrate the extensive range of GE automation products, here are ten related models that complement the GE Fanuc and cater to specialized needs:

1. **GE IS200DSFCG1AEB**: A digital signal processor for complex control applications.

2. **GE IC660BBA020**: A versatile I/O module that expands functionality in automation systems.

3. **GE DS200DDTBG2A**: A digital output terminal board for precise control operations.

4. **GE IS200TRPGH1BDE**: Designed for turbine control, providing specialized functionalities for power generation.

5. **GE IC200CPU005**: A powerful CPU for small to medium-sized automation tasks.

6. **GE IC693APU301**: An analog processing unit that enhances the GE Fanuc's capabilities in handling analog signals.

7. **GE VMIVME-7671-421000**: A versatile VME interface module that can be integrated with the GE Fanuc for greater flexibility.

8. **GE HE693RTM705**: A remote terminal module that enhances connectivity and control.

9. **GE IS220PPDAH1A**: A process controller that offers additional control functionalities.

10. **GE DS200SIOCG1A**: A serial I/O module that complements the GE Fanuc’s communication capabilities.

In conclusion, the GE Fanuc is a powerful and versatile industrial automation solution that meets the diverse needs of today’s manufacturing and process control environments. Its robust performance, scalability, and user-friendly design make it an ideal choice for businesses looking to enhance their operational efficiency. With its extensive compatibility and integration capabilities, the GE Fanuc ensures seamless connectivity within the broader range of GE automation products, making it a cornerstone of modern industrial automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the ever-evolving world of industrial automation, GE Fanuc stands out as a trusted name synonymous with innovation, reliability, and performance. The GE Fanuc model is engineered to meet the rigorous demands of modern manufacturing and process control, ensuring that your operations run smoothly and efficiently. Below, we delve into the key technical features of the GE Fanuc, explore various usage scenarios, compare it with other models, and highlight related products within the extensive GE automation products lineup.

Key Technical Features

The GE Fanuc model brings together cutting-edge technology and user-centric design to deliver exceptional performance. Here are some of its key technical features:

1. **High Performance Processing**: Equipped with advanced processors, the GE Fanuc model ensures rapid data processing and response times, crucial for real-time applications in industrial settings.

2. **Robust Connectivity Options**: This model supports multiple communication protocols, making it compatible with a wide range of devices and systems. Its Ethernet and serial communication capabilities allow seamless integration into existing networks.

3. **Scalability**: Designed to grow with your business, the GE Fanuc model offers scalable solutions that can be easily expanded to accommodate increased production demands or additional functionalities.

4. **Versatile I/O Configuration**: With a variety of input and output modules, this model can be tailored to meet specific application requirements, ensuring flexibility in both configuration and deployment.

5. **User-Friendly Interface**: The GE Fanuc features an intuitive interface that simplifies programming and monitoring, empowering operators to efficiently manage processes and quickly respond to any issues that arise.

6. **Enhanced Reliability**: Built with industrial-grade components, the GE Fanuc model is designed to withstand harsh operating conditions, ensuring minimal downtime and maximum productivity.

Usage Scenarios

The GE Fanuc model is ideal for a variety of applications across different industries. Here are some typical usage scenarios:

1. **Manufacturing Automation**: In factories, the GE Fanuc can control robotic arms, conveyor systems, and assembly lines, facilitating streamlined production processes and enhancing operational efficiency.

2. **Process Control**: In chemical and petrochemical industries, the GE Fanuc excels at monitoring and controlling complex processes, managing variables such as temperature, pressure, and flow rates to ensure product quality and safety.

3. **Energy Management**: The GE Fanuc is utilized in energy management systems, allowing for real-time monitoring of energy consumption and automating controls to optimize energy use and reduce costs.

4. **Water Treatment**: In municipal water treatment facilities, this model aids in managing water purification processes, ensuring compliance with environmental regulations while maintaining operational efficiency.

5. **Building Automation**: The GE Fanuc is integrated into building management systems, controlling HVAC systems, lighting, and security, thereby enhancing comfort while maximizing energy savings.

Comparison with Other Models

When compared to other models within the GE automation products lineup, the GE Fanuc distinguishes itself through its balance of performance and versatility. For instance:

– **GE SR750**: While the SR750 is known for its superior processing speed, the GE Fanuc offers a broader range of I/O options, making it more adaptable for diverse applications.

– **GE IS200DSPXH2DBD**: The IS200DSPXH2DBD model specializes in digital signal processing, but the GE Fanuc provides a more comprehensive set of features for general automation tasks.

– **GE IC695CPE310-ABAH**: Although the IC695CPE310-ABAH is a robust PLC with excellent communication capabilities, the GE Fanuc’s user-friendly interface often makes it a preferred choice for operators seeking ease of use.

– **GE IS200JPDMG1ADC**: This model focuses on specific control tasks, while the GE Fanuc is more versatile, capable of handling a wider array of control and monitoring functions.

Overall, the GE Fanuc is a well-rounded solution that can effectively address the needs of various industries while competing favorably against other models.

Related Models

To further illustrate the extensive range of GE automation products, here are ten related models that complement the GE Fanuc and cater to specialized needs:

1. **GE IS200DSFCG1AEB**: A digital signal processor for complex control applications.

2. **GE IC660BBA020**: A versatile I/O module that expands functionality in automation systems.

3. **GE DS200DDTBG2A**: A digital output terminal board for precise control operations.

4. **GE IS200TRPGH1BDE**: Designed for turbine control, providing specialized functionalities for power generation.

5. **GE IC200CPU005**: A powerful CPU for small to medium-sized automation tasks.

6. **GE IC693APU301**: An analog processing unit that enhances the GE Fanuc's capabilities in handling analog signals.

7. **GE VMIVME-7671-421000**: A versatile VME interface module that can be integrated with the GE Fanuc for greater flexibility.

8. **GE HE693RTM705**: A remote terminal module that enhances connectivity and control.

9. **GE IS220PPDAH1A**: A process controller that offers additional control functionalities.

10. **GE DS200SIOCG1A**: A serial I/O module that complements the GE Fanuc’s communication capabilities.

In conclusion, the GE Fanuc is a powerful and versatile industrial automation solution that meets the diverse needs of today’s manufacturing and process control environments. Its robust performance, scalability, and user-friendly design make it an ideal choice for businesses looking to enhance their operational efficiency. With its extensive compatibility and integration capabilities, the GE Fanuc ensures seamless connectivity within the broader range of GE automation products, making it a cornerstone of modern industrial automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.