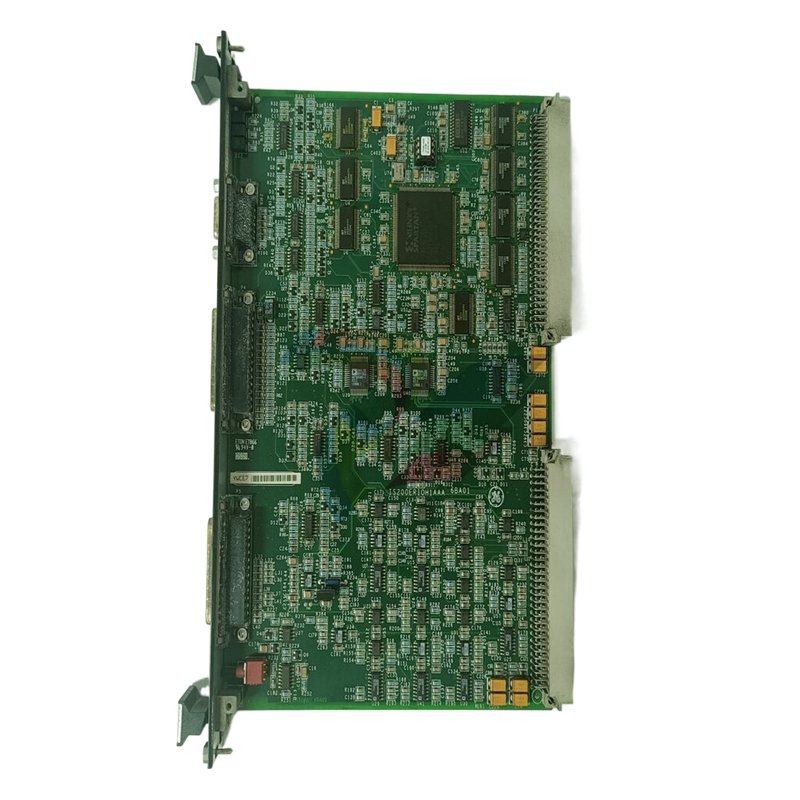

GE Fanuc IC693CBL301 PAC Systems RX3i

Introducing the GE Fanuc Model, a cutting-edge solution at the forefront of industrial automation technology. Renowned for its reliability and performance, GE Fanuc products are designed to meet the ever-evolving demands of modern industries. This model embodies the perfect blend of advanced features, flexibility, and performance, making it an essential component for systems requiring precise control and efficiency.

Key Technical Features:

The GE Fanuc Model boasts an array of technical specifications that set it apart in the realm of automation products. It features a robust processing unit optimized for real-time applications, enabling seamless data handling and rapid response to operational changes. With support for diverse input and output configurations, this model accommodates a wide range of sensors and actuators, offering unparalleled flexibility in system design.

One of its standout features is the integrated communication capabilities, supporting multiple industrial protocols such as Ethernet/IP, Modbus TCP, and Profinet. This ensures easy integration with existing systems and facilitates efficient data exchange across different devices. Additionally, the GE Fanuc Model is equipped with advanced diagnostic tools, providing users with comprehensive insights into system performance and enabling proactive maintenance.

Another notable feature is its rugged design, built to withstand harsh industrial environments. With a wide operating temperature range and resistance to dust and moisture, this model is ideal for applications in manufacturing, energy, and transportation sectors. Its modular architecture allows for easy scalability, making it suitable for both small-scale operations and large industrial setups.

Usage Scenarios:

The versatility of the GE Fanuc Model makes it a perfect fit for various applications across different industries. In manufacturing, it can be utilized for process automation, controlling machinery, and monitoring production lines to ensure optimal efficiency. The model's real-time data processing capability allows for immediate adjustments, reducing downtime and enhancing productivity.

In the energy sector, the GE Fanuc Model plays a critical role in managing power distribution and monitoring renewable energy sources. Its robust communication features enable seamless integration with smart grid technologies, ensuring reliable operation and efficient energy management. Furthermore, in the transportation industry, this model is instrumental in automating control systems for trains, traffic signals, and other critical infrastructure, enhancing safety and operational efficiency.

Comparison with Other Models:

When compared to other models within the GE lineup, such as the GE SR750 and GE IC697MDL740, the GE Fanuc Model stands out due to its advanced communication capabilities and enhanced processing power. While the SR750 is known for its reliability in basic automation tasks, the GE Fanuc Model offers greater flexibility and performance for complex applications.

In comparison to the GE IS200DSPXH2DBD, which excels in motion control, the GE Fanuc Model provides a more comprehensive solution for various automation needs, making it suitable for diverse industrial settings. Additionally, when looking at the GE IC200CPU005, which is primarily focused on small-scale applications, the GE Fanuc Model offers greater scalability and robustness for larger industrial environments.

Related Models:

To give you a broader perspective on the GE automation products available, here are ten related models worth considering:

1. GE SR750 – A reliable controller designed for basic automation tasks.

2. GE IS200DSPXH2DBD – Focused on motion control applications with precision.

3. GE IC200CPU005 – Ideal for small-scale automation needs.

4. GE IC697MDL740 – A modular design with extensive I/O options.

5. GE IS200EDFFH1ABA – Known for its versatility in various control applications.

6. GE IC660BBA020 – A reliable solution for process automation.

7. GE IS200JPDMG1ADC – Specialized in digital process control.

8. GE IC694PWR331 – A power supply module supporting various GE Fanuc controllers.

9. GE IS200TRPGH1BDE – Designed for advanced communications and control.

10. GE DS200DDTBG2A – A digital input/output terminal board for enhanced connectivity.

In summary, the GE Fanuc Model is a powerful and versatile solution that stands at the pinnacle of GE automation products. Its array of advanced features, adaptability to various industrial applications, and superior performance make it an invaluable asset for any organization looking to enhance their automation capabilities. With its robust design and comprehensive support for modern communication protocols, the GE Fanuc Model is engineered to meet the demands of today’s complex industrial environments, ensuring long-term reliability and efficiency. Whether you're in manufacturing, energy, or transportation, integrating the GE Fanuc Model into your operations will undoubtedly pave the way for increased productivity and streamlined processes. Explore the full range of GE automation products today and discover how they can transform your industrial landscape.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc Model boasts an array of technical specifications that set it apart in the realm of automation products. It features a robust processing unit optimized for real-time applications, enabling seamless data handling and rapid response to operational changes. With support for diverse input and output configurations, this model accommodates a wide range of sensors and actuators, offering unparalleled flexibility in system design.

One of its standout features is the integrated communication capabilities, supporting multiple industrial protocols such as Ethernet/IP, Modbus TCP, and Profinet. This ensures easy integration with existing systems and facilitates efficient data exchange across different devices. Additionally, the GE Fanuc Model is equipped with advanced diagnostic tools, providing users with comprehensive insights into system performance and enabling proactive maintenance.

Another notable feature is its rugged design, built to withstand harsh industrial environments. With a wide operating temperature range and resistance to dust and moisture, this model is ideal for applications in manufacturing, energy, and transportation sectors. Its modular architecture allows for easy scalability, making it suitable for both small-scale operations and large industrial setups.

Usage Scenarios:

The versatility of the GE Fanuc Model makes it a perfect fit for various applications across different industries. In manufacturing, it can be utilized for process automation, controlling machinery, and monitoring production lines to ensure optimal efficiency. The model's real-time data processing capability allows for immediate adjustments, reducing downtime and enhancing productivity.

In the energy sector, the GE Fanuc Model plays a critical role in managing power distribution and monitoring renewable energy sources. Its robust communication features enable seamless integration with smart grid technologies, ensuring reliable operation and efficient energy management. Furthermore, in the transportation industry, this model is instrumental in automating control systems for trains, traffic signals, and other critical infrastructure, enhancing safety and operational efficiency.

Comparison with Other Models:

When compared to other models within the GE lineup, such as the GE SR750 and GE IC697MDL740, the GE Fanuc Model stands out due to its advanced communication capabilities and enhanced processing power. While the SR750 is known for its reliability in basic automation tasks, the GE Fanuc Model offers greater flexibility and performance for complex applications.

In comparison to the GE IS200DSPXH2DBD, which excels in motion control, the GE Fanuc Model provides a more comprehensive solution for various automation needs, making it suitable for diverse industrial settings. Additionally, when looking at the GE IC200CPU005, which is primarily focused on small-scale applications, the GE Fanuc Model offers greater scalability and robustness for larger industrial environments.

Related Models:

To give you a broader perspective on the GE automation products available, here are ten related models worth considering:

1. GE SR750 – A reliable controller designed for basic automation tasks.

2. GE IS200DSPXH2DBD – Focused on motion control applications with precision.

3. GE IC200CPU005 – Ideal for small-scale automation needs.

4. GE IC697MDL740 – A modular design with extensive I/O options.

5. GE IS200EDFFH1ABA – Known for its versatility in various control applications.

6. GE IC660BBA020 – A reliable solution for process automation.

7. GE IS200JPDMG1ADC – Specialized in digital process control.

8. GE IC694PWR331 – A power supply module supporting various GE Fanuc controllers.

9. GE IS200TRPGH1BDE – Designed for advanced communications and control.

10. GE DS200DDTBG2A – A digital input/output terminal board for enhanced connectivity.

In summary, the GE Fanuc Model is a powerful and versatile solution that stands at the pinnacle of GE automation products. Its array of advanced features, adaptability to various industrial applications, and superior performance make it an invaluable asset for any organization looking to enhance their automation capabilities. With its robust design and comprehensive support for modern communication protocols, the GE Fanuc Model is engineered to meet the demands of today’s complex industrial environments, ensuring long-term reliability and efficiency. Whether you're in manufacturing, energy, or transportation, integrating the GE Fanuc Model into your operations will undoubtedly pave the way for increased productivity and streamlined processes. Explore the full range of GE automation products today and discover how they can transform your industrial landscape.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.